- Turning and sizing ring blanks and bands

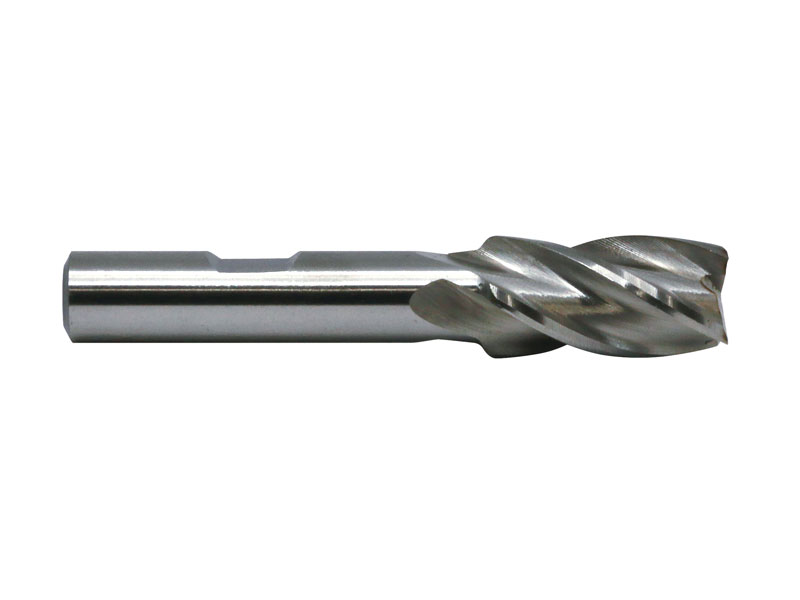

- Machining ring mandrels and expanding mandrels

- Cutting and finishing bezels, settings, and prongs

- Making collet-held parts and small precision components

- Truing and modifying stone setting tools

- Fabricating custom jigs, fixtures, and specialty tools

- Light turning of precious and non-precious metals

- Working with wax, plastic, aluminum, and steel for prototypes and tooling

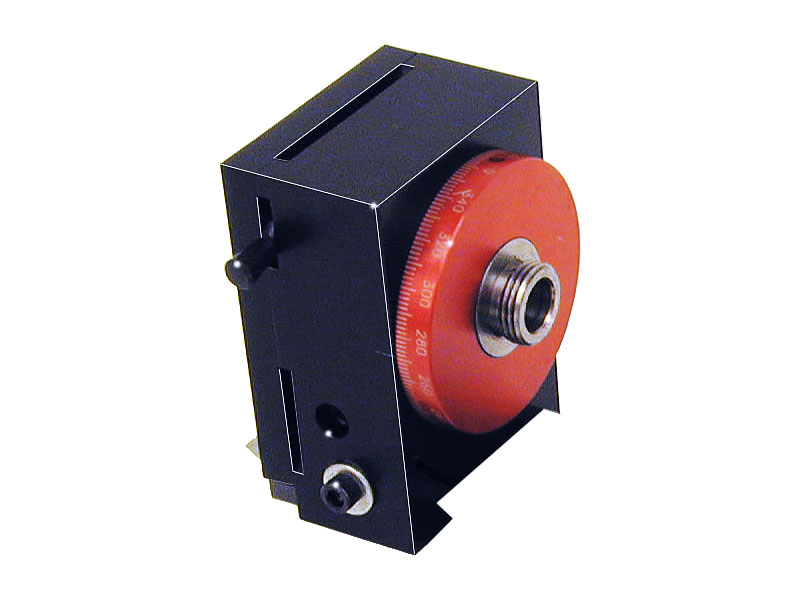

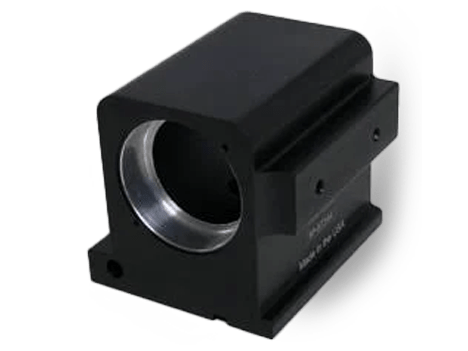

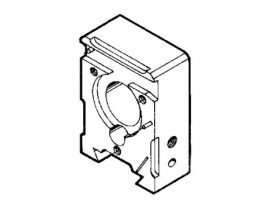

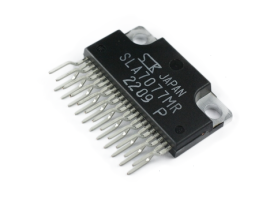

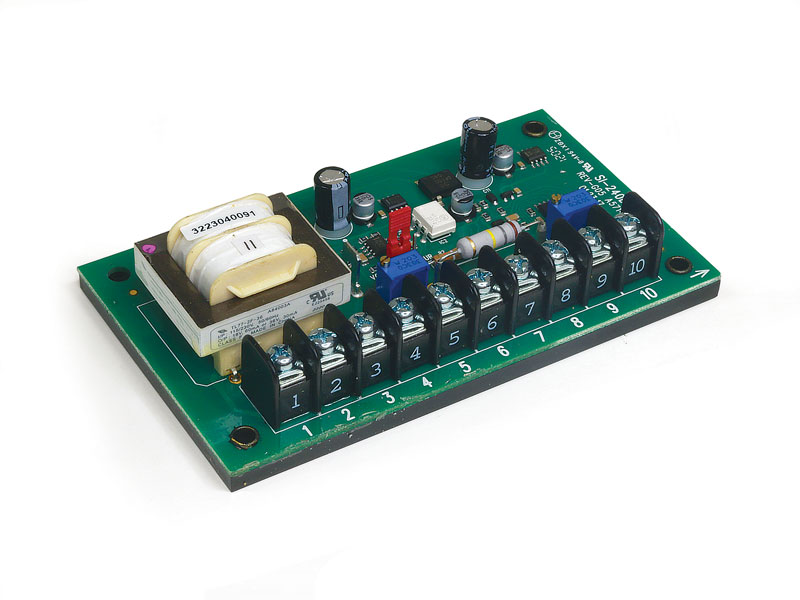

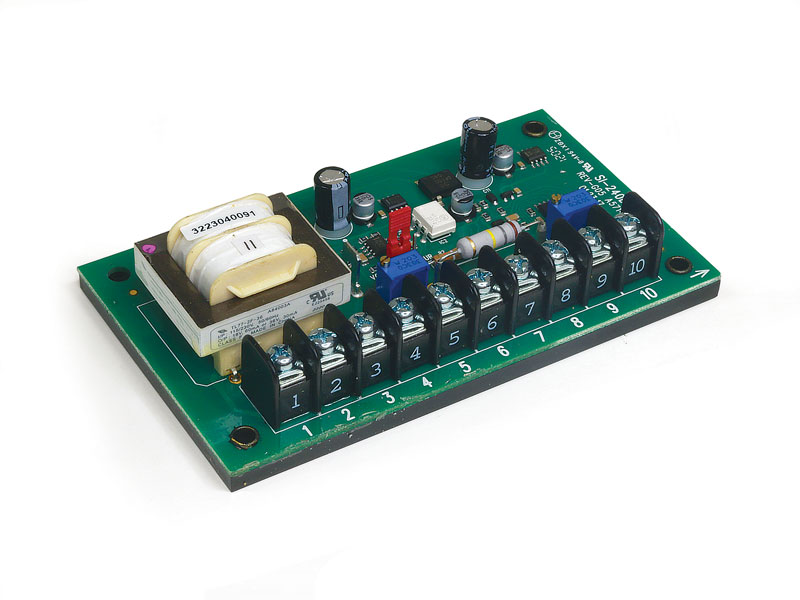

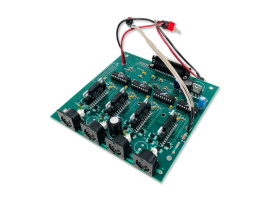

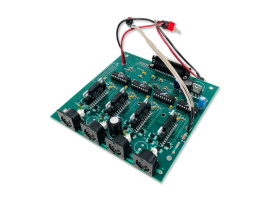

- Centroid Acorn CNC control board

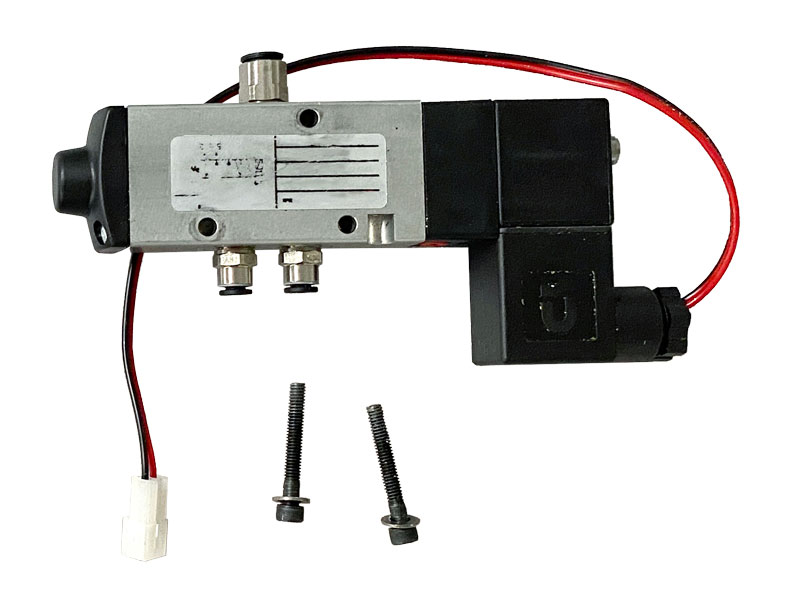

- Acorn plug-and-play relay module (mounted and pre-wired)

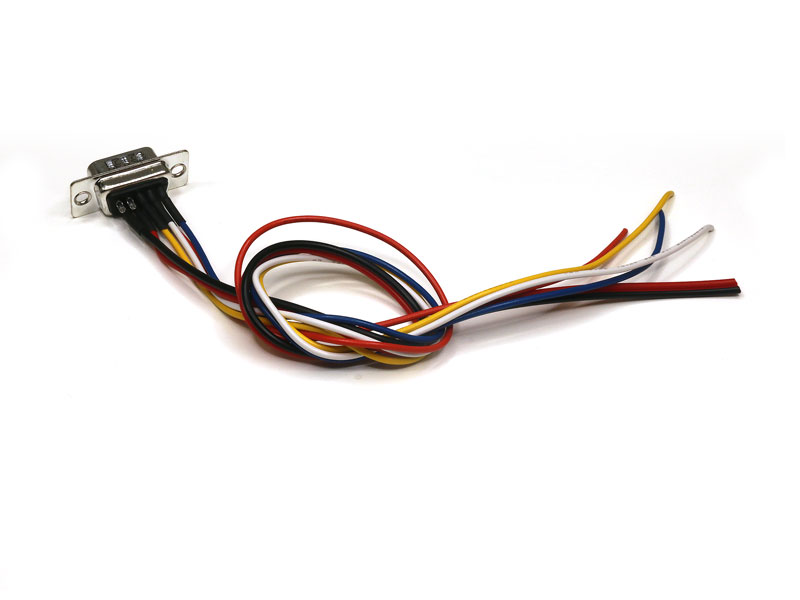

- Internal wiring to DB9, DB25, and 2-wire Molex connectors

- Power supply, push-to-reset circuit breaker, and cooling fan

- External Ethernet port, power switch, and power LED

- Ethernet connection

- Power switch and power LED

- Cooling fan

- Three DB25 connectors:

- Sherline 4-axis driver box

- Aux 4-axis control for additional drives/axes

- Relay card

- Three DB9 connectors:

- Limit switches

- External encoder*

- Aux tool setter or touch probe (one at a time)

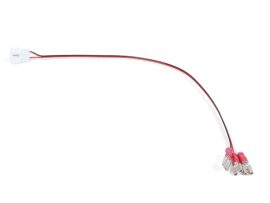

- Three 2-wire Molex connectors:

- E-stop button

- Spindle control

- Laser

- Dual logic power: 5 VDC and 24 VDC

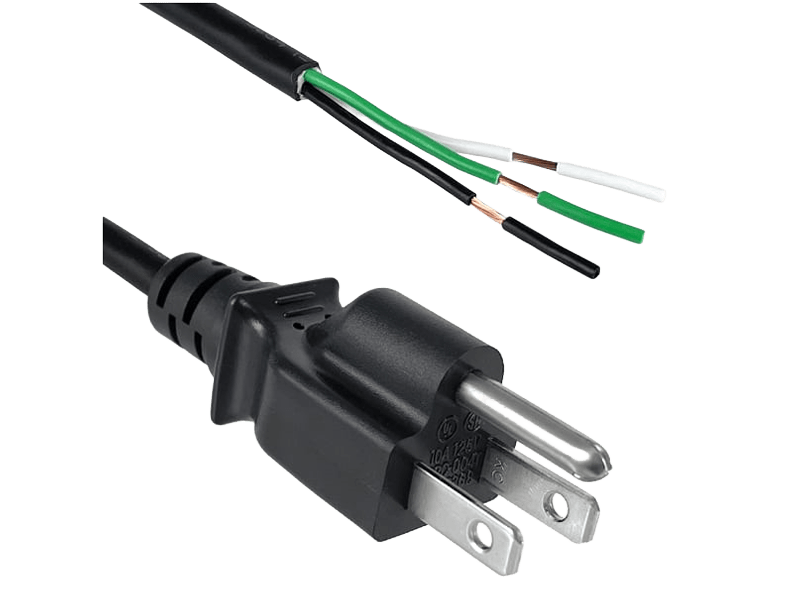

- Input power: 100–120 VAC or 208–240 VAC, 50/60 Hz

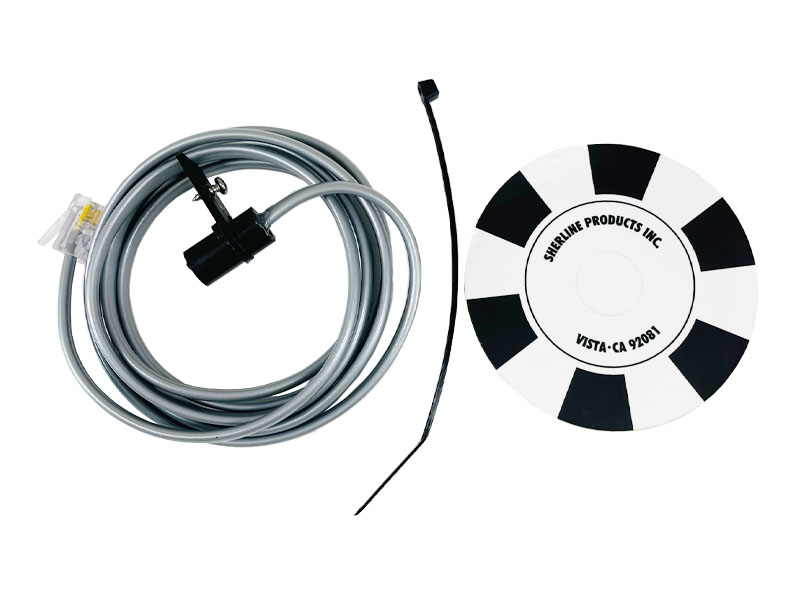

- 15 ft shielded Ethernet cable (controller to PC)

- External E-stop with 2 ft cord

- The controller connects directly to Sherline 24 V stepper motors via the Sherline 4-axis driver box (P/N 8760).

- Not compatible with MASSO 36 V closed-loop stepper motors.

- For DIY users with their own motors/drives, use the “Aux 4-axis” DB25 connector. Wiring information for DIY customers is available under the Specifications/Downloads.

- Program directly from hand sketches or prints

- Import DXF files and generate G-code without separate CAD/CAM

- Ideal for new CNC users and those unfamiliar with traditional G-code programming

- Buys CNC-ready Sherline machines and installs their own motors, drives, and encoders.

- Purchase the base Sherline/Acorn CNC Controller (P/N 9400) without options and wire to your own hardware.

- Upgrading an existing Sherline CNC system including older OEM systems such as Denford, D&M, LabVolt, Paxton-Patterson, or Light Machines. For a sample Denford/Sherline Microlathe conversion using Acorn, see: Centroid Denford/Sherline Microlathe Conversion

- If you already have a Sherline Linux PC or 4-axis driver box, configure the controller

with:

- Spindle Control Isolator Board

- External Encoder kit for your headstock (Standard or 3C)

- Wants a complete Sherline system: CNC-ready machine, 24 V stepper motors, 4-axis driver box, spindle control isolator board, and external encoder.

- The Sherline/Acorn Controller is designed to support all of these configurations.

- To control spindle speed via G-code, you must have a motor drive or the Spindle Control Isolator Board and an external encoder installed.

- These components work together to accurately acquire and control spindle RPM.

- If you do not include the Spindle Control Isolator Board at the time of purchase, adding it later will require returning the controller to Sherline for installation. Email orders@sherline.com for return instructions.

-

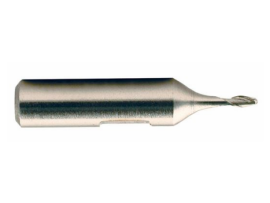

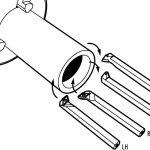

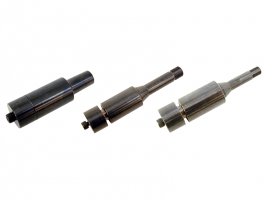

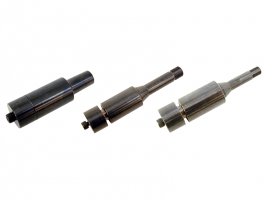

P/N 2078 holds jeweler’s burrs with a 3/32" shank.

-

P/N 2079 is designed for Dremel® tools and other cutters with a 1/8" shank.

- P/N 2080 holds jeweler’s burrs with a 3mm shank.

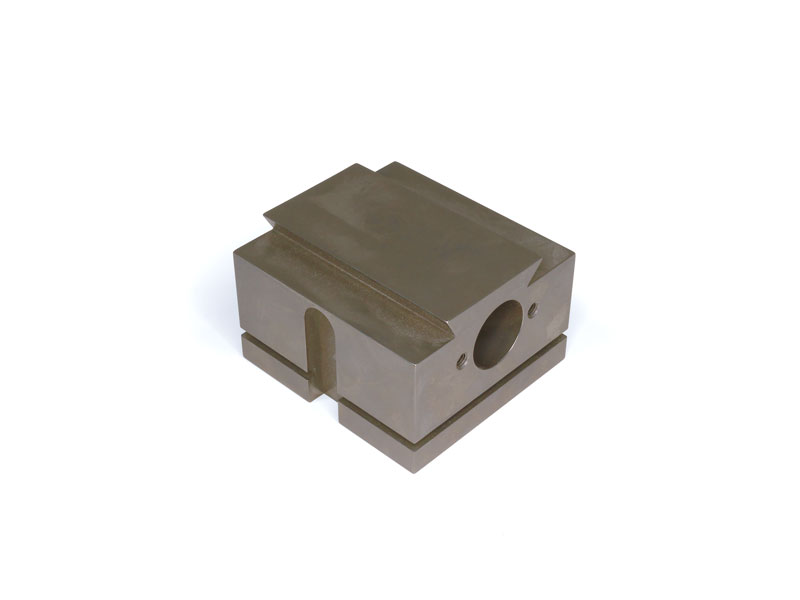

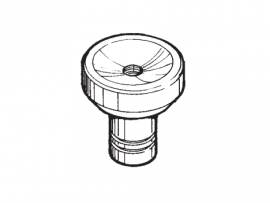

- Made from 12L14 steel with electroless nickel plating for corrosion resistance

- Tapered body provides greater visual access to the stone during cutting

- ¼" dop hole with 10-32 set screw to secure the dop

- 3/32" locating pin for alignment of angle-cut dops

- Precision-machined with tight tolerances for a secure, accurate fit

- Keyed dop system ensures repeatable orientation and alignment

- Fully compatible with Ultra Tec® brand dops and machines

- High-quality construction - Made in the USA

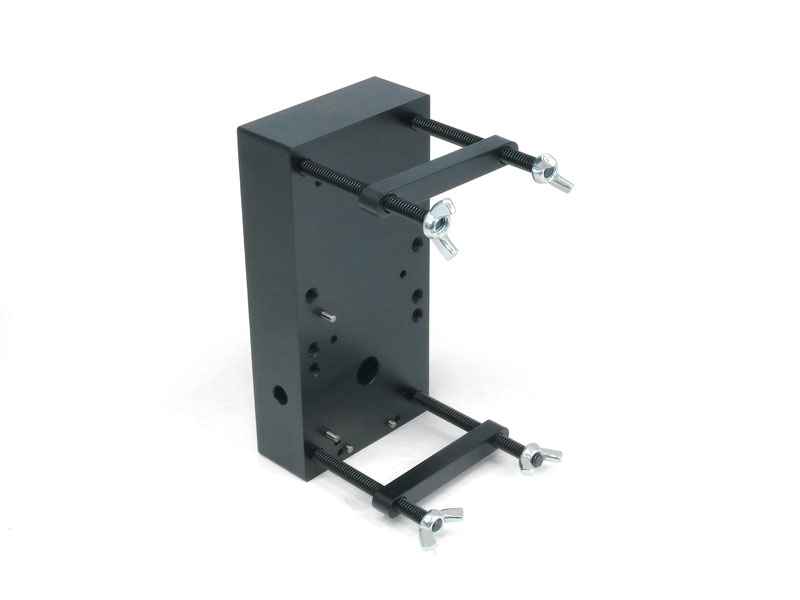

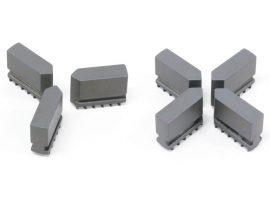

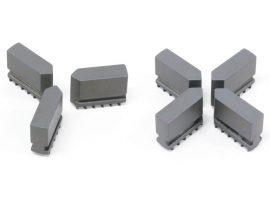

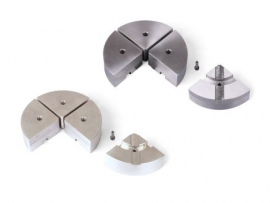

- Four Versagrip jaw inserts

- Four socket head cap screws (not shown)

- Two Versagrip top jaws

- Four 82° screws

-

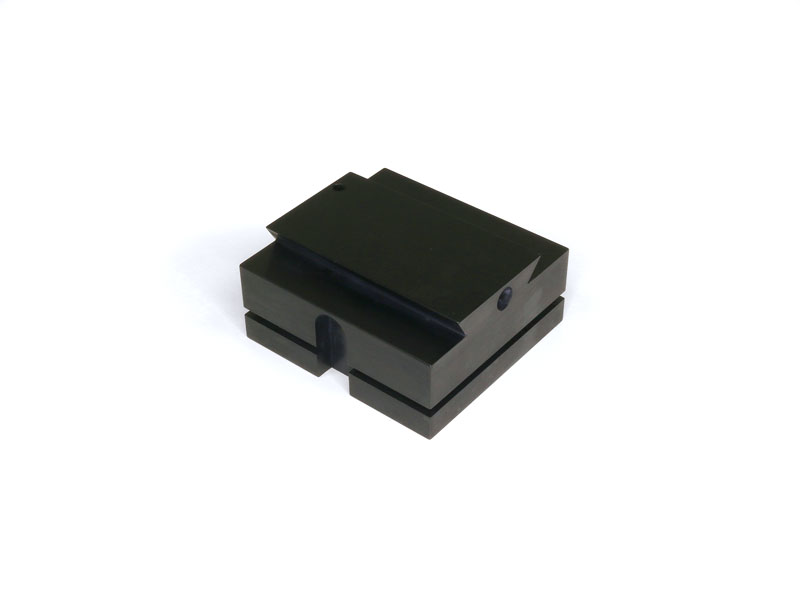

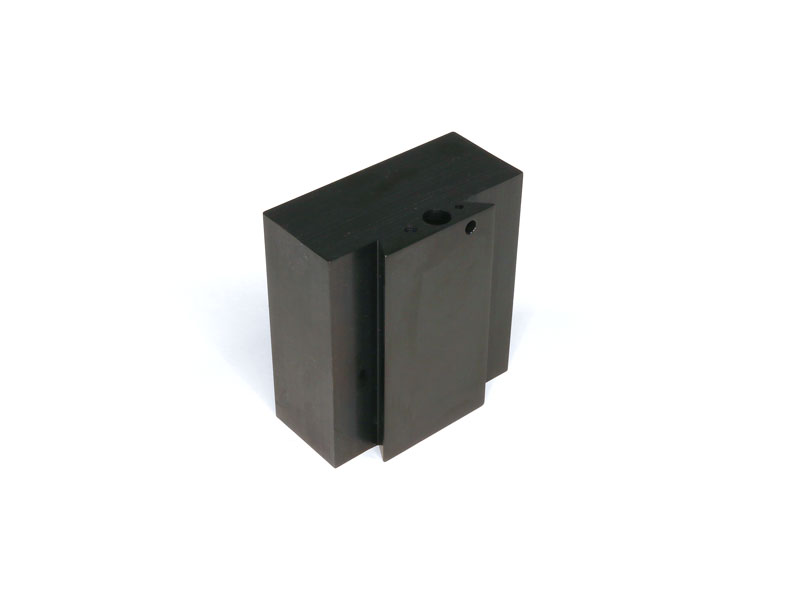

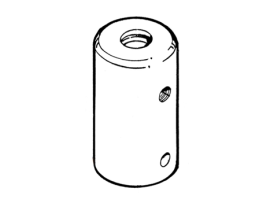

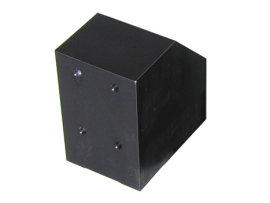

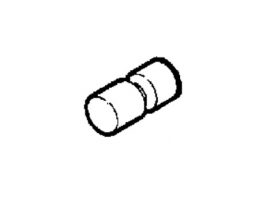

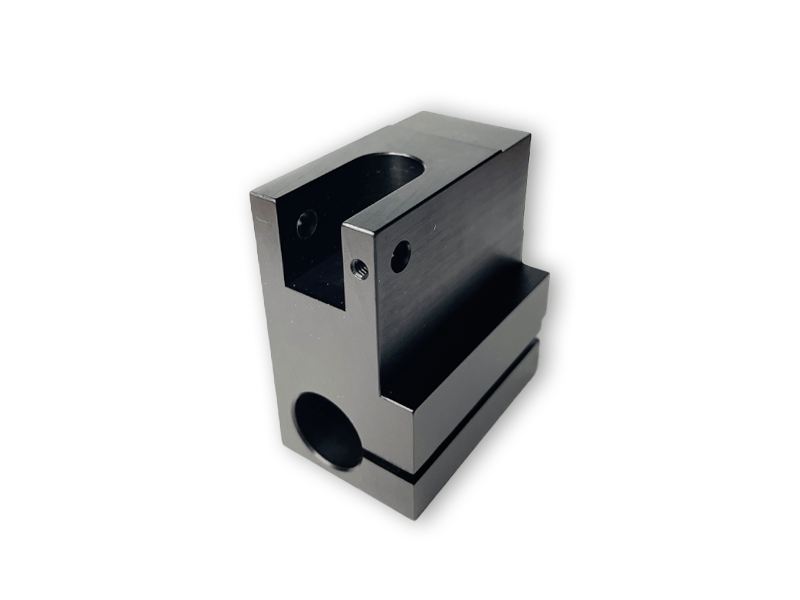

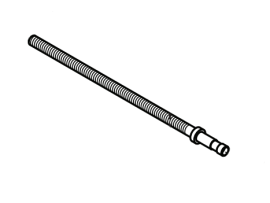

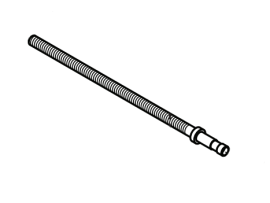

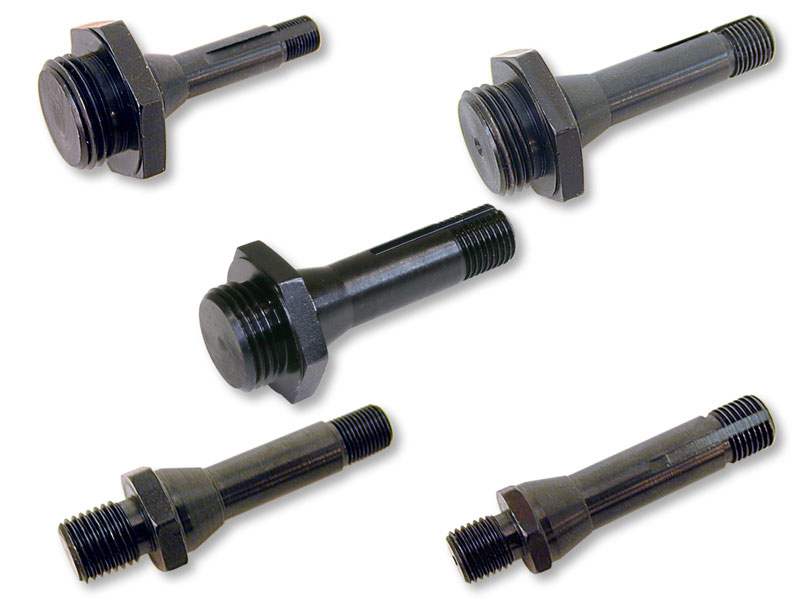

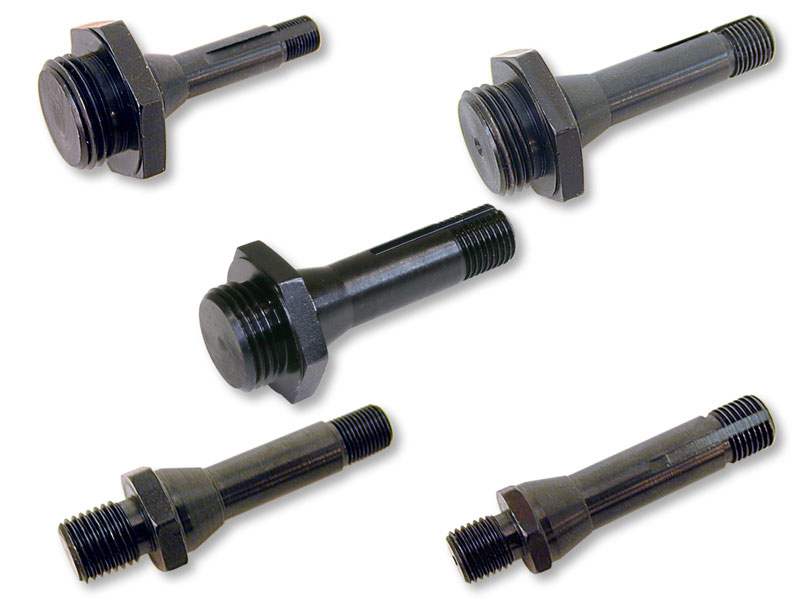

Each holder is 3-1/4" long and can bore to a depth of just over 2" when secured with two set screws.

-

Constructed from 1144 Stressproof® steel with a black oxide finish for strength and corrosion resistance.

-

Each holder is 3-1/4" long and can bore to a depth of just over 2" when secured with two set screws.

-

Constructed from 1144 Stressproof® steel with a black oxide finish for strength and corrosion resistance.

-

Each holder is 3-1/4" long and can bore to a depth of just over 2" when secured with two set screws.

-

Constructed from 1144 Stressproof® steel with a black oxide finish for strength and corrosion resistance.

-

Each holder is 3-1/4" long and can bore to a depth of just over 2" when secured with two set screws.

-

Constructed from 1144 Stressproof® steel with a black oxide finish for strength and corrosion resistance.

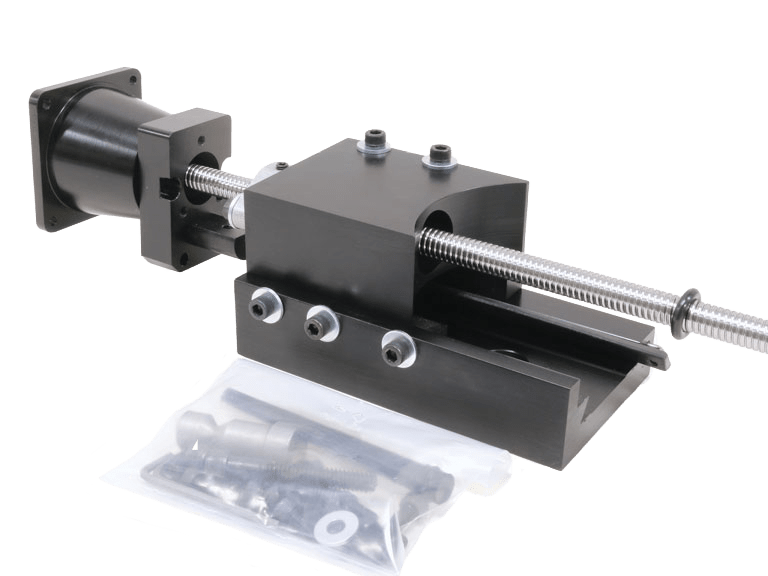

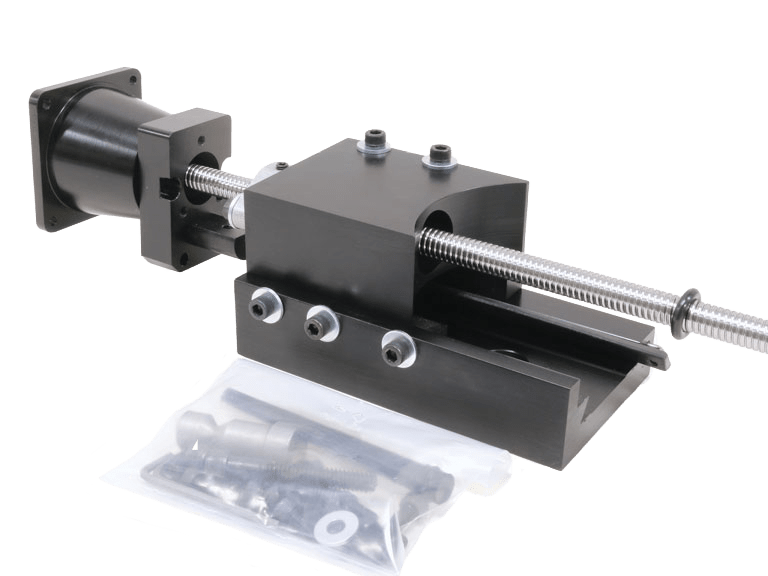

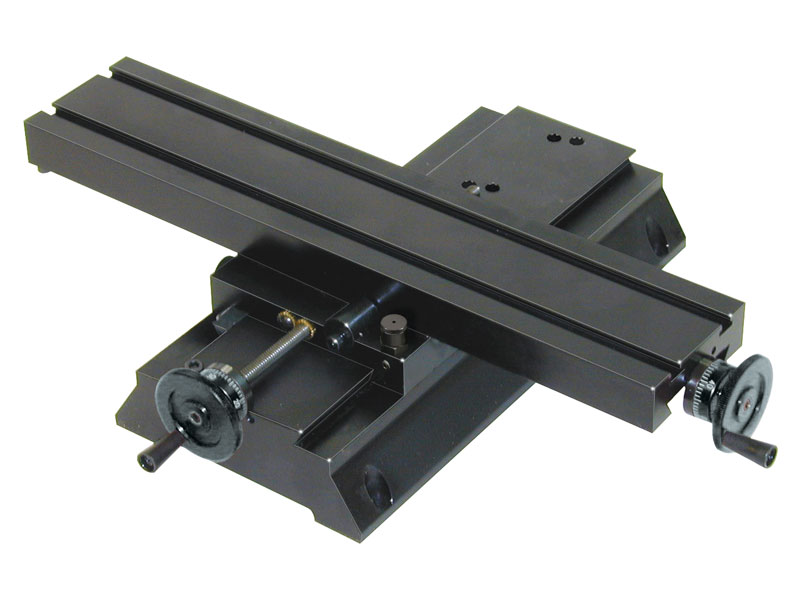

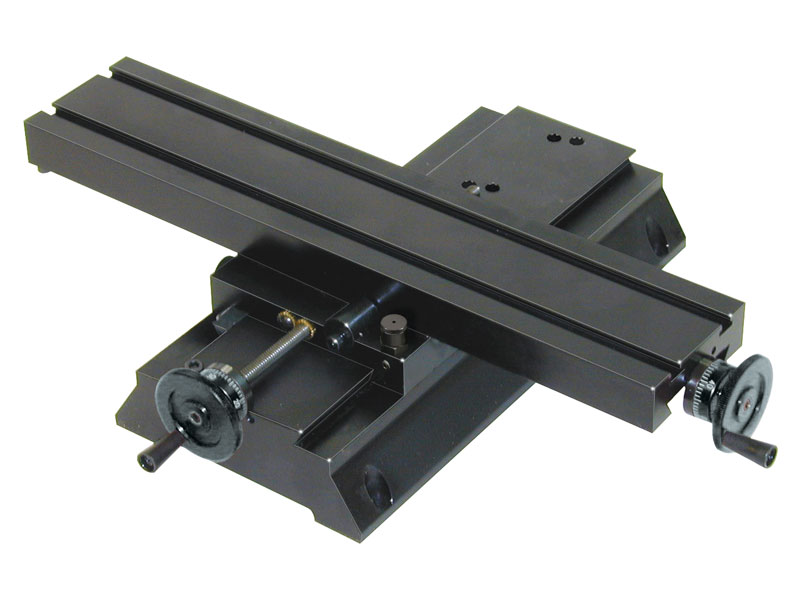

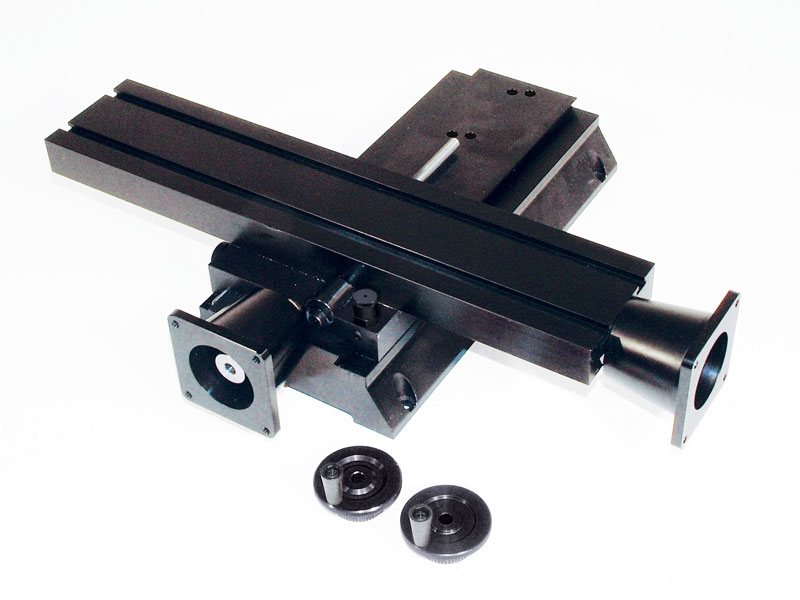

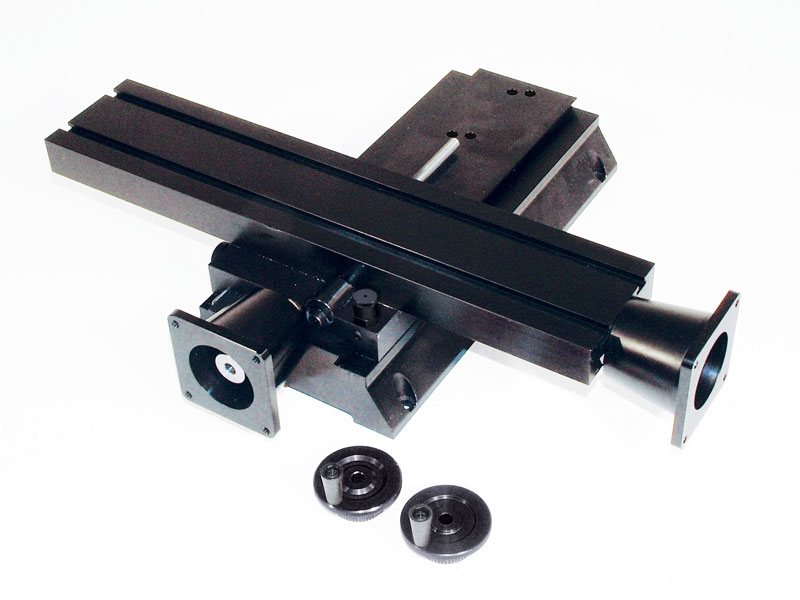

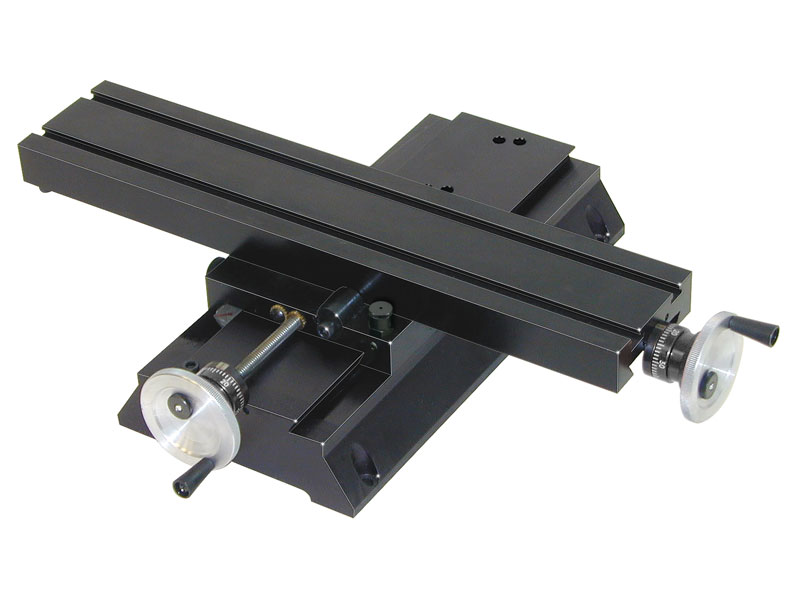

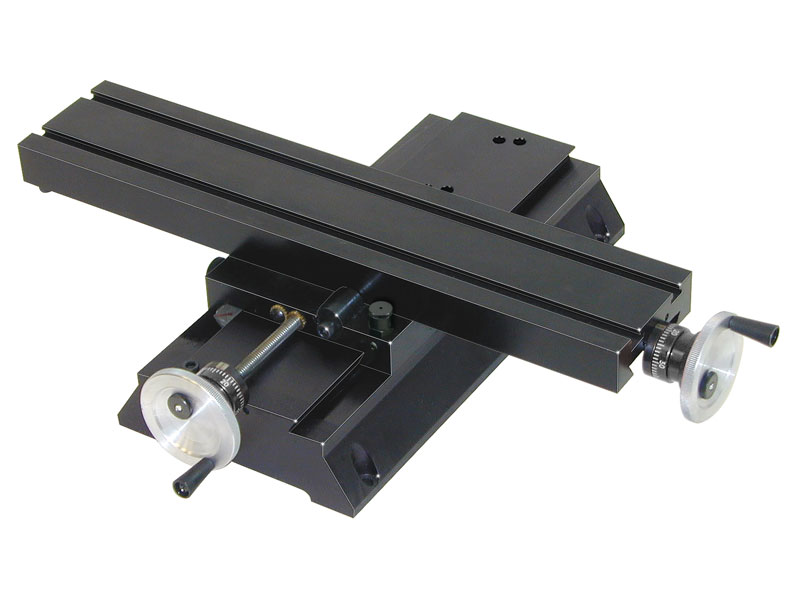

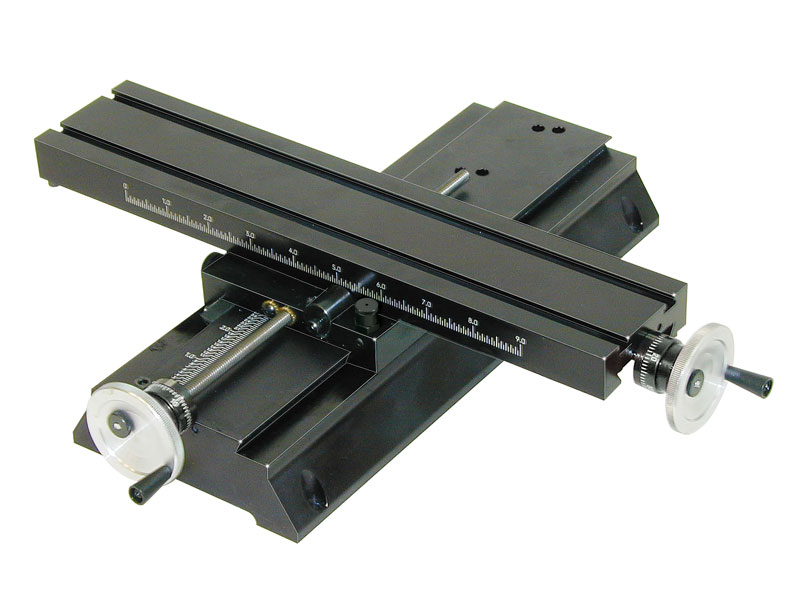

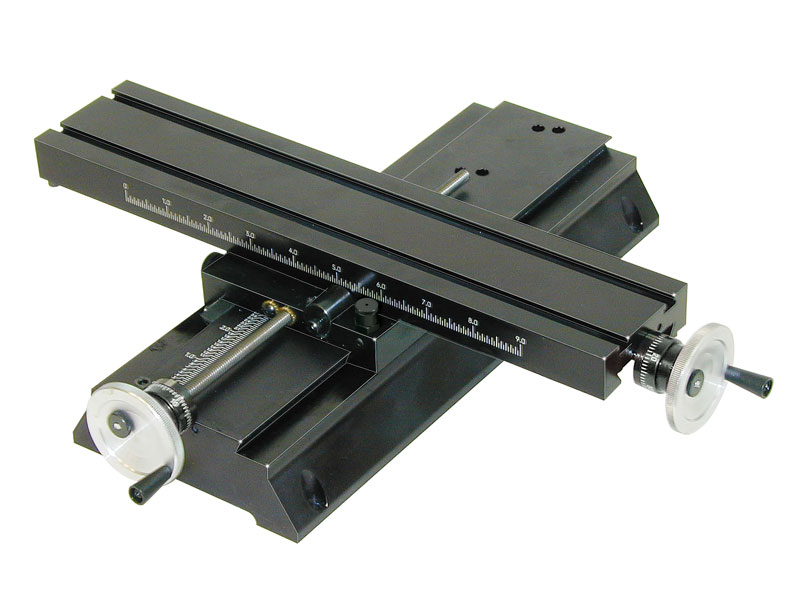

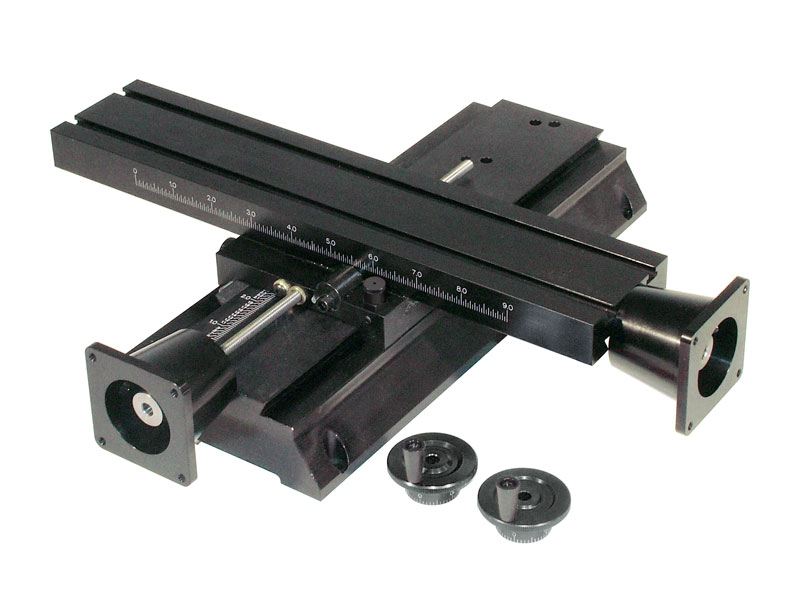

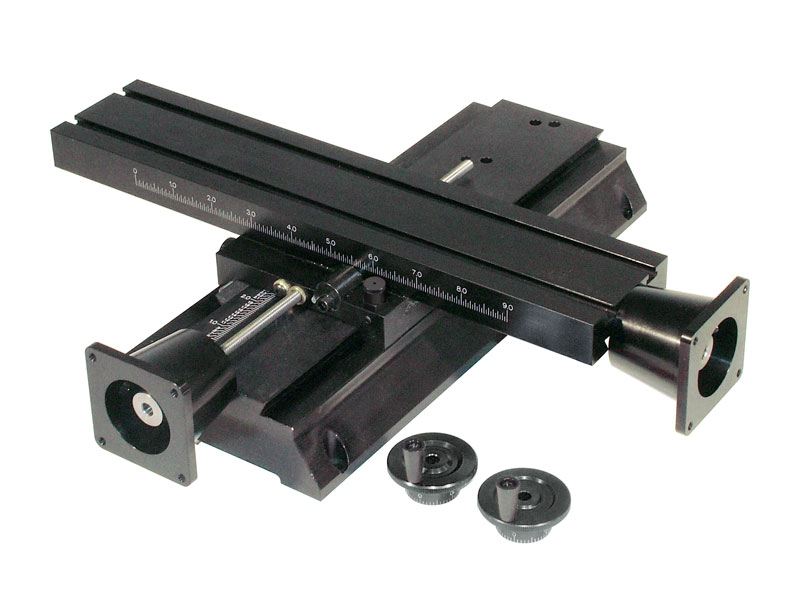

- Better positional accuracy and smoother CNC motion on the X and Y axes

- Fully assembled components ready to install

- Works with high-torque stepper motors for improved performance

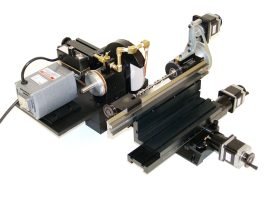

- Built-in Driver box (Converts g-code to steps to run DC stepper motors)

- Output cables for X, Y, Z, and A pre-wired with DIN plugs for stepper motors

- Keyboard and mouse (you supply the monitor)

- Processor Speed: 2 GHz or faster

- RAM: 2 GB

- Hard Drive: 500 GB

- Internal drive: DVD-RW

- External drive: 4 GB USB Flash drive for transferring g-code files

- Current: Internal switches are set to 110VAC but can be reset for operation with 230 VAC

- Installed software: Ubuntu 12.04 Linux-based OS with Linux CNC 2.6.11 4-axis CNC software.

- 90-day warranty on CNC and computer-related components.

- Keyboard and mouse (you supply the monitor)

- Processor Speed: 2 GHz or faster

- RAM: 2 GB

- Hard Drive: 500 GB

- Internal drive: DVD-RW

- External drive: 4 GB USB Flash drive for transferring g-code files

- Current: Internal switches are set to 110VAC but can be reset for operation with 230 VAC

- Installed software: Ubuntu 12.04 Linux-based OS with Linux CNC 2.6.11 4-axis CNC software.

- 90-day warranty on CNC and computer-related components.

-

3/8" square shank, compatible with standard 3/8" insert tool posts

-

5° offset angle provides better tool clearance for complex operations

-

Tip height is 0.375" from the base, meeting industry standards

-

Constructed from case-hardened steel with a durable black oxide finish

-

80° inserts are ideal for roughing cuts

-

55° insert holders are also available for sharper corner access

-

Each insert can be rotated 180°, giving you two cutting edges per insert

-

Maintain a sharp edge when cutting exotic alloys or abrasive materials

-

Enable faster cutting speeds and improved surface finishes

-

A 55° right-hand insert, suitable for starting holes as small as 3/4", ideal for reaching sharp internal corners

-

An 80° insert, which fits into a smaller 1/2" hole and offers added strength for roughing operations

-

Longer-lasting edges when cutting hard metals like stainless steel, titanium, or abrasive materials such as carbon fiber

-

Faster cutting speeds and greater efficiency

-

Each insert can be rotated 180°, effectively giving you two cutting edges per insert

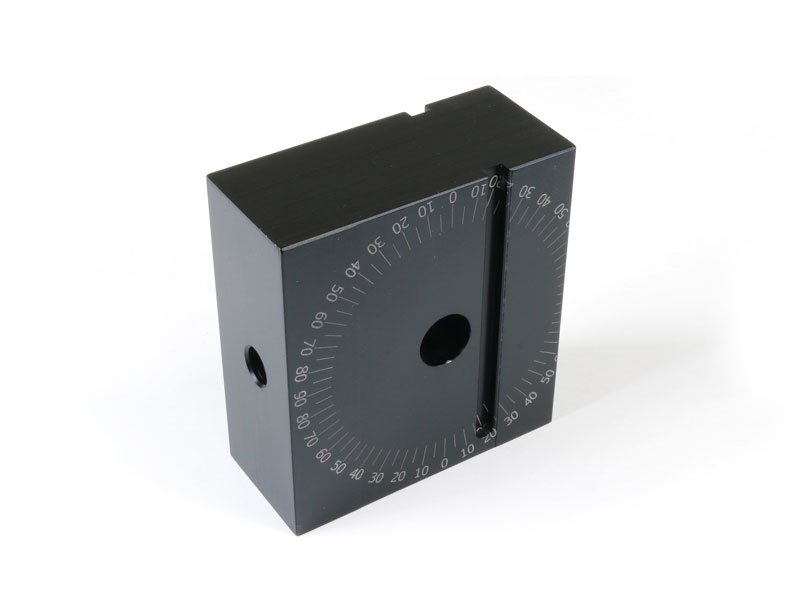

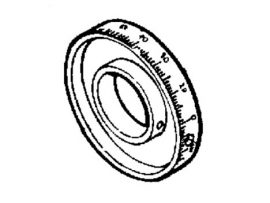

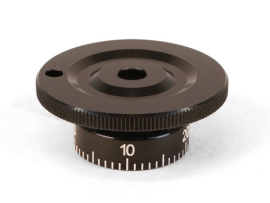

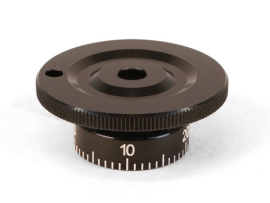

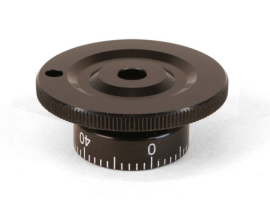

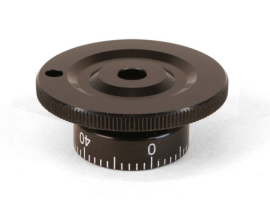

- Inch: 50-divisions

- Metric: 100-divisions

- Inch: 50-divisions

- Metric: 100-divisions

- 60° threading insert for cutting outside threads (P/N 22675)

- .031" insert (P/N 2269)

- .062" insert (P/N 2270)

- .094" insert (P/N 22694)

- .125" insert (P/N 22695)

- .031" radius insert (P/N 22692)

- .062" radius insert (P/N 22693)

-

#1 drill: 1/8" shank

-

#2 drill: 3/16" shank

-

#3 drill: 1/4" shank

-

P/N 3061 is suited for holes with a minimum diameter of 1/4" (6.4 mm) and a maximum cutting depth of 0.600" (15.2 mm).

-

P/N 3063 works with a minimum hole diameter of 5/16" (7.9 mm) and provides up to 1.00" (25 mm) of cutting depth.

-

P/N 3064 also fits a 5/16" (7.9 mm) minimum hole but offers an extended 1.5" (38.1 mm) reach.

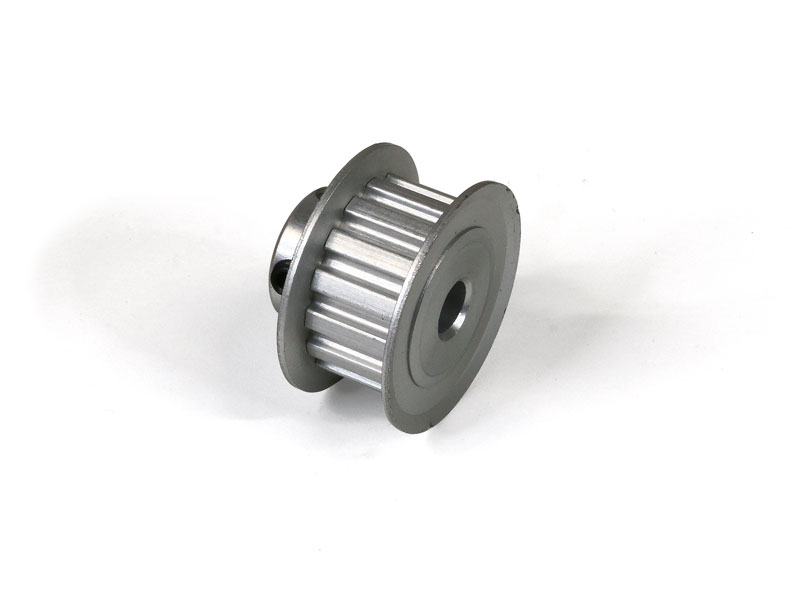

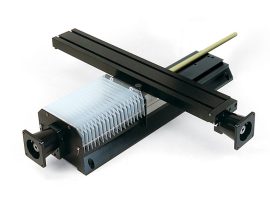

- 15 aluminum gears

- Mounting brackets

- Engagement mechanism

- 4.00" (102 mm) handwheel

-

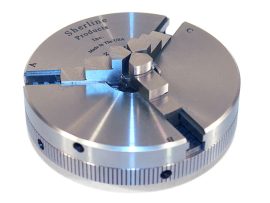

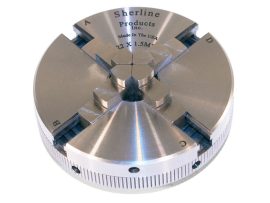

If you prefer jaws with a looser fit for faster operation (where maximum accuracy isn’t critical), add a note requesting “loose jaws” below.

-

Soft steel jaws (unhardened and unmachined) are also available when building your own chuck.

- Inch: 50-divisions

- Metric: 100-divisions

-

Each insert offers six usable cutting edges:

-

Rotate 120° to access a new edge (3 per side), then

-

Flip the insert for 3 more cutting points on the opposite face

-

-

In comparison, traditional carbide inserts offer only 2–4 cutting edges, making ceramic inserts cost-effective over time, despite the higher upfront cost.

-

Ceramic inserts are brittle and should be used with proper technique to avoid chipping or breakage.

-

Caution: Chips produced during cutting can be extremely hot—even red-hot. Use protective eyewear, gloves, and fire-safe clothing when operating.

-

Some materials, such as tool steel, may form long, stringy chips that wrap around the part ("bird’s nest" effect).

Use a chip brush and stop the machine frequently to clear chips. These chip clusters can ignite if they come in contact with hot chips. -

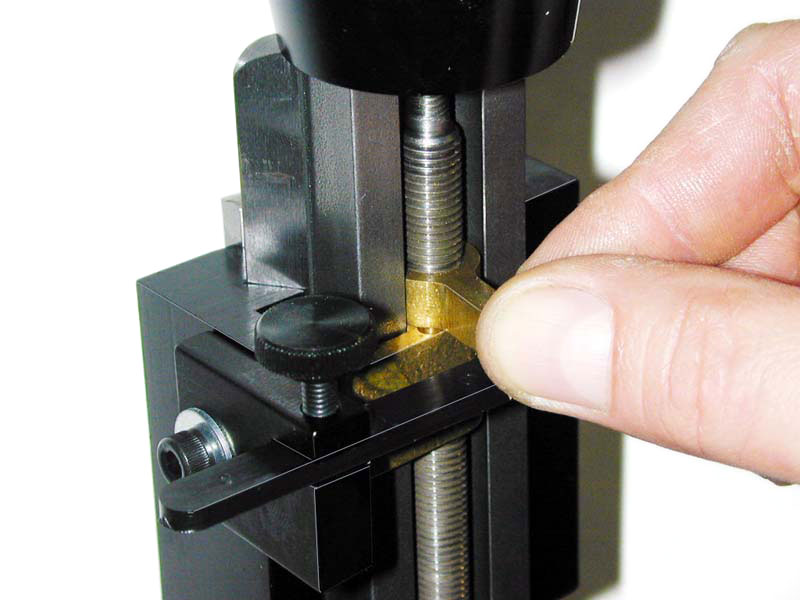

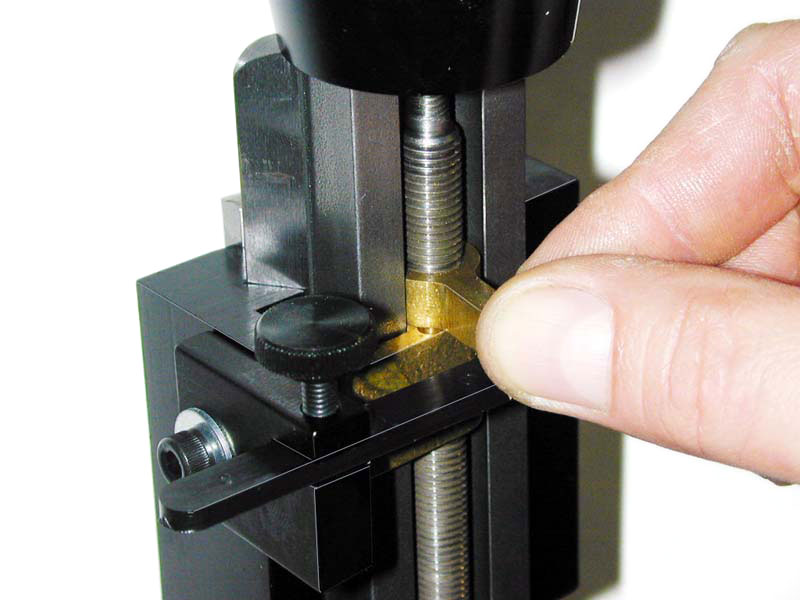

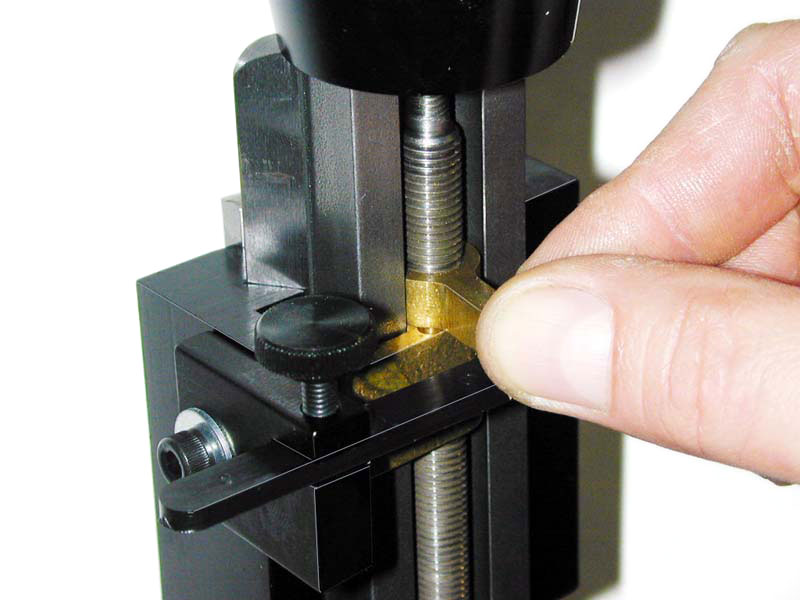

Use a bench grinder or file to slightly grind down the back side of the clamp (see blue circle in the image).

-

This will allow the clamp tip to clear the step (indicated by the red arrow), ensuring full contact and proper clamping of the insert.

-

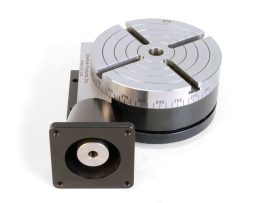

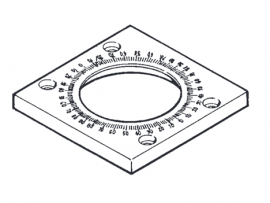

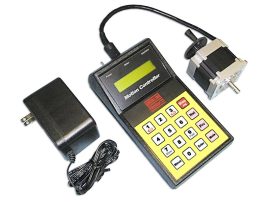

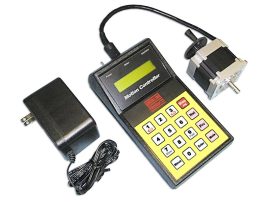

4" Sherline rotary table with pre-installed stepper motor

-

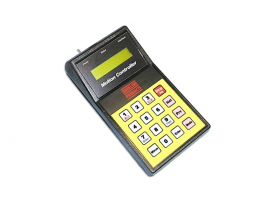

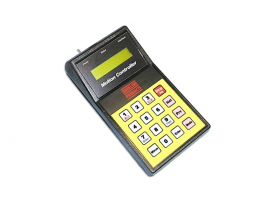

Microprocessor unit with numeric keypad

-

115 VAC power supply (universal 110–240 VAC compatible)

-

All required connecting cables

-

Right-Angle Attachment: Holds the table vertically at a 2.7" center height. A matching right-angle tailstock is also available for supporting long workpieces.

-

Tilting Angle Table: Allows mounting at any angle from 0° to 90°. At 90°, the center height remains 2.7", compatible with the right-angle tailstock.

-

Resolution: 28,800 steps per revolution

-

Accuracy: ±0.006° per step

-

Accepts input signals from an external CNC controller

-

Sends “completion” signals back to the master controller

-

Can be daisy-chained with other units for coordinated actions

-

Horizontal orientation: 50 lbs

-

Vertical orientation: 30 lbs

-

Vertical rotational torque: 6 ft-lbs (e.g., able to lift a 6 lb. weight 12" from the center)

-

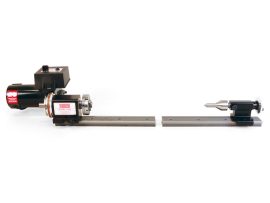

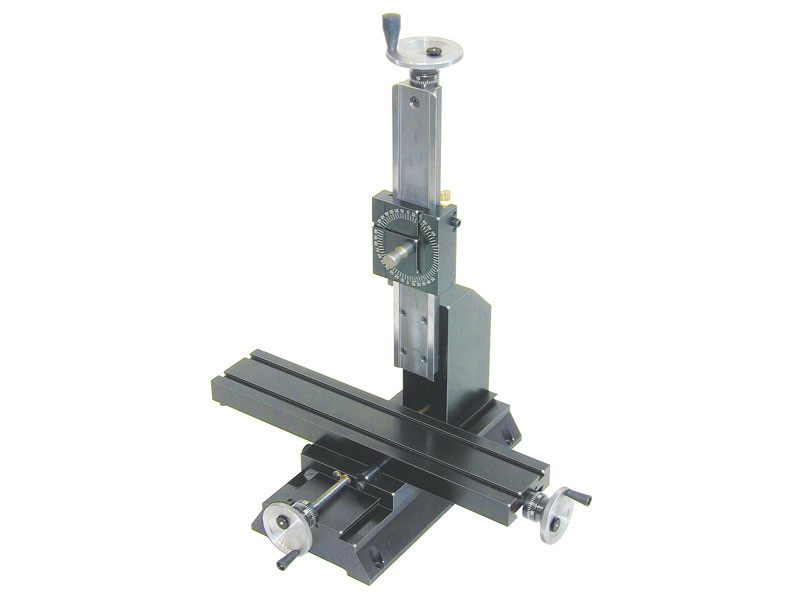

Linear controller with integrated keypad

-

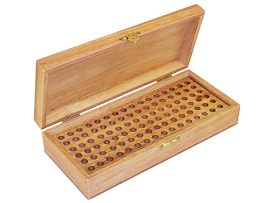

Inch Collets: Part numbers begin with 1160, followed by two digits representing the size in 64ths of an inch.

-

Example: P/N 116013 is 13/64"; P/N 116016 is 1/4" (16/64").

-

-

Metric Collets: Part numbers begin with 1178, followed by two digits representing the size in 0.1 mm increments.

-

Example: P/N 117813 is 1.3 mm.

-

-

Inch sizes from 1/64" to 5/16", in 64th-inch increments.

-

Metric sizes from 0.3 mm to 8.0 mm, in 0.1 mm increments.

-

Linear Controller with Keypad

-

Power Supply

-

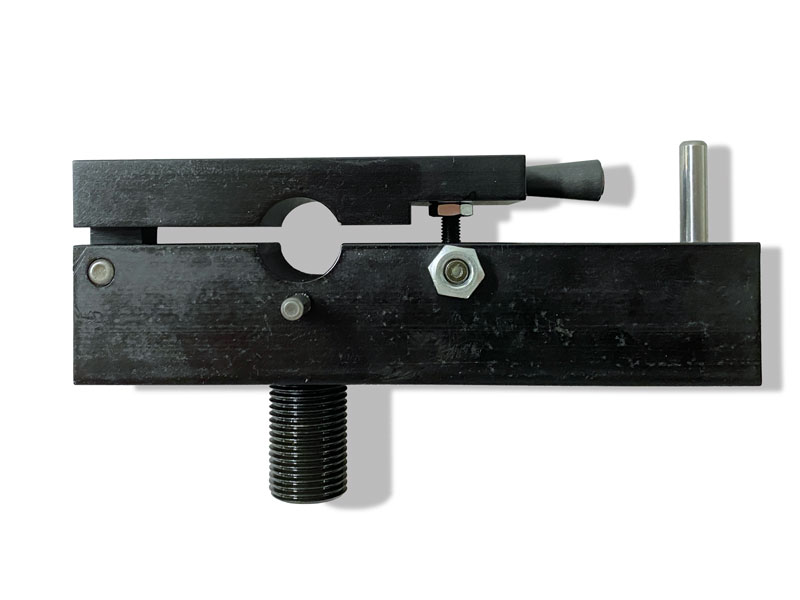

Talon Grip Vise Jaw Inserts by Mitee-Bite

-

Reversible Jaw Inserts (smooth/serrated) by Saunders

-

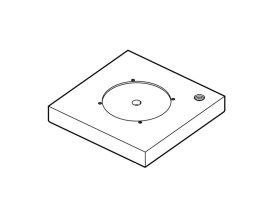

Fixed base plate

-

Movable base plate

-

Adjustable stop

-

3 hex keys (7/32", 5/32", 3/32")

-

Mounting screws and T-nuts

-

Reversible Jaw Inserts:

One side is serrated for gripping raw stock, and the other is smooth for holding finished parts with minimal marking. Easily reversible in the top jaw (includes 1 insert and 4 screws). -

Talon Grip Vise Jaw Inserts:

Double-sided serrated inserts for aggressive holding of raw stock. The serrated edge enhances grip strength (includes 2 inserts and 2 screws). -

MB Versagrip Vise Jaws & Inserts:

Serrated on both sides for secure gripping of raw or irregular material. Compatible only with the Versagrip jaws (includes 4 inserts and 4 screws). -

MB Hard Stop:

Designed to fit in the fixed jaw insert slot and used alongside the Talon Grip Inserts for repeatable part positioning. -

Jaw inserts are sold separately. The Standard MB Vise Fixture Base Plates are required to mount any jaw inserts.

-

Although the serrated inserts are intended for raw stock, they may be used on finished surfaces if light clamping pressure is applied and only light machining or engraving is performed.

-

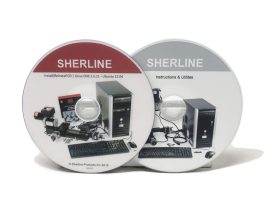

DVD: Linux operating system (Ubuntu v12.04) with LinuxCNC software (v2.6.11)

-

CD: Installation and troubleshooting instructions, along with free or low-cost utilities, including AutoEditNC, ACE Converter, MeshCAM, DeskEngrave, Freemill, Inkscape, and FreeCAD

-

Inch: 1/4-20 leadscrew, 50 divisions

-

Metric: 6.3 x 1 mm leadscrew, 100 divisions

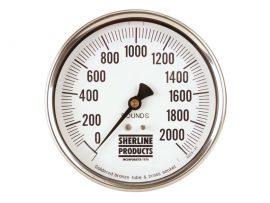

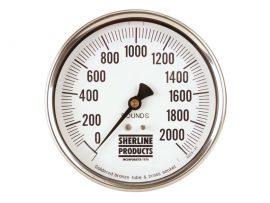

- 80290 - is used the on LM2-2000 scale (0-2000 lbs.)

- 80300 - is used on the LM2-5000 scale (0-5000 lbs.)

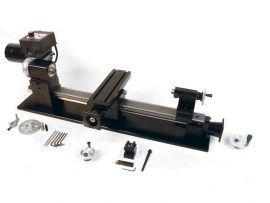

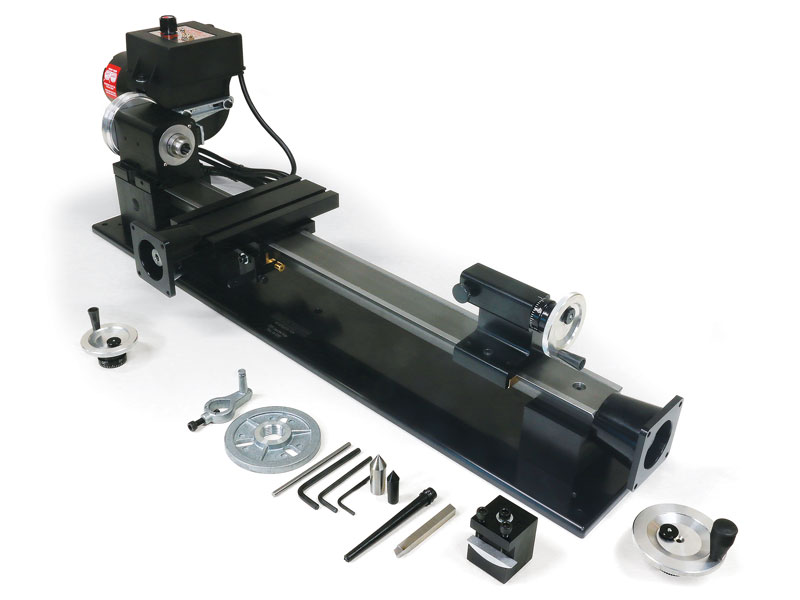

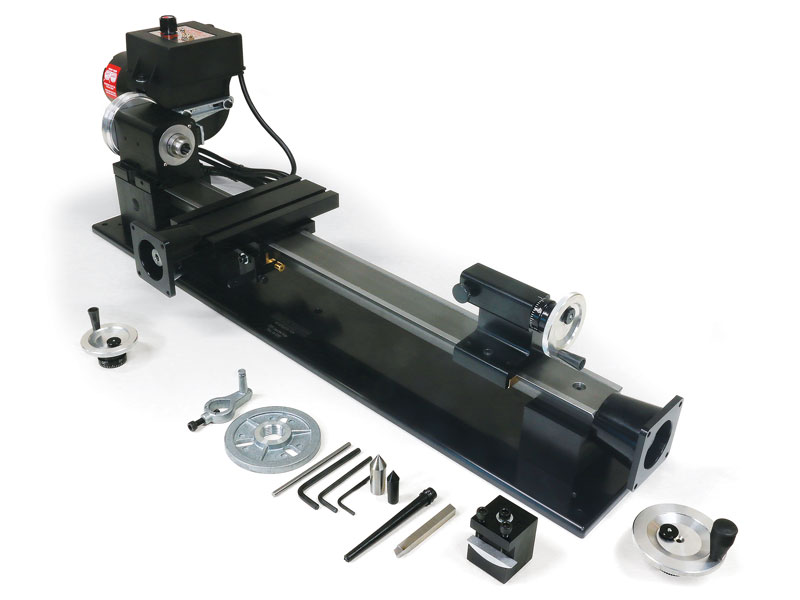

- A powerful 90V DC motor with electronic speed controller*

- 2.75" (70mm) x 6.0" (152mm) crosslide

- 15" (381mm) steel bed to allow 8" (203mm) between centers

- Standard 1-5/8" (41mm) laser-engraved aluminum handwheels

- Pulleys, drive belt, faceplate, lathe dog, two dead centers, three hexagonal keys, tool post, sharpened high-speed steel cutting tool, eight-foot three-wire power cord, and instruction manual

-

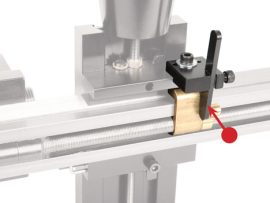

Maintains a constant feed rate for smoother, more consistent surface finishes

-

Minimizes errors from miscounting handwheel revolutions

-

Eliminates physical effort during long cuts or when returning the saddle to the starting position

-

Linear controller with keypad

-

Power supply

-

#23 frame size stepper motor

-

Cables

-

Stepper motor mount

-

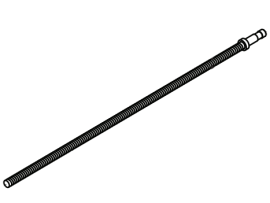

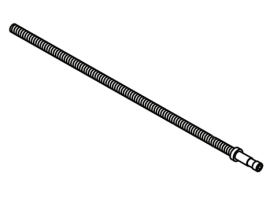

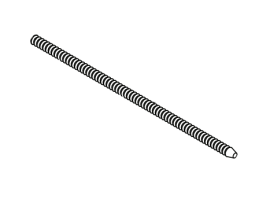

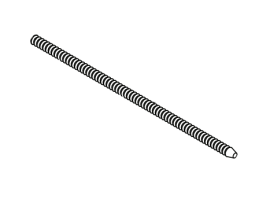

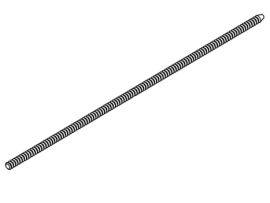

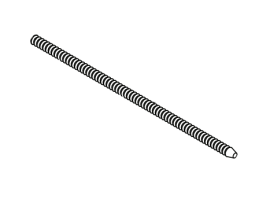

15" leadscrew

-

Dampened coupling

-

Preload nuts

-

Drill guide block

-

Complete installation and operating instructions

-

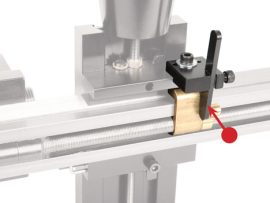

Provides a constant feed rate for a smoother, more consistent surface finish

-

Reduces the chance of errors caused by miscounting handwheel revolutions

-

Eliminates physical effort for long cuts or returning the saddle to the starting position

-

Linear controller with integrated keypad

-

Power supply

-

#23 frame size stepper motor

-

Cables

-

Stepper motor mount

-

24" leadscrew

-

Dampened coupling

-

Preload nuts

-

Drill guide block

-

Complete installation and operating instructions

-

Linear controller with integrated keypad

-

Power supply

-

#23 frame size stepper motor

-

Cables

-

Stepper motor mount

-

Dampened coupling

-

Preload nuts

-

Drill guide block

-

Complete installation and operation instructions

- A constant feed rate gives a smoother, more consistent final finish

- The chance of errors due to miscounting handwheel revolutions is reduced

- No physical effort is needed for long cuts or returning the saddle to its starting position after a cut is complete

- Linear Controller w/Keypad

- Power Supply

- #23 Frame Size Stepper Motor

- Cables

- Stepper motor mount

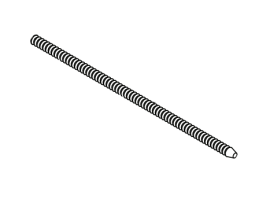

- Z-axis Leadscrew

- Dampened coupling

- Preload nuts

- Drill guide block and complete installation and use instructions

-

Linear controller with keypad

-

Power supply

-

#23 frame size stepper motor

-

Cables

-

Complete instructions

- NEMA 23 frame size – fits Sherline CNC-ready mills, lathes, and rotary tables.

- Dual-shaft design – both ends of the shaft are usable; flats are ground on each end for secure attachment of handwheels and couplings.

- Standard step angle – 1.8° per step (200 steps/rev) for precise motion control.

- 2.0 A/phase – both motors are rated at 2.0 amps and work with existing Sherline CNC power supplies and driver electronics.

- 6-lead wiring – allows use in a variety of bipolar or unipolar configurations (see spec sheets for wiring diagrams).

- Designed for Sherline CNC – plug-and-play with Sherline driver boxes and motion controllers when used with the supplied connectors.

- Coupler requirement: Because of the increased torque, the high-torque motor (P/N 67126) must be used with the updated CNC coupling (P/N 671052). This coupling replaces the older 3-slot coupling (P/N 67105).

- Motor mounts: When used with a Sherline stepper motor mount (P/N 67101), be sure that the shaft entering the coupling has a flat aligned with the set screw. Tightening against the round shaft can damage the shaft and make removal difficult.

- Handwheel use: The dual-shaft design lets you mount a handwheel on the rear shaft for manual operation when the drivers are powered down. When the motors are energized, they hold position and cannot be moved easily by hand.

- Controller compatibility: P/N 67127 with the 5-pin DIN plug is designed to plug directly into Sherline’s 4-axis driver box, CNC systems, and linear and rotary controllers. P/N 67130 (no plug) is intended for non-Sherline or custom controllers.

- Inch models show position to 0.0005″ (three and a half decimal places)

- Metric models show position to 0.01 mm

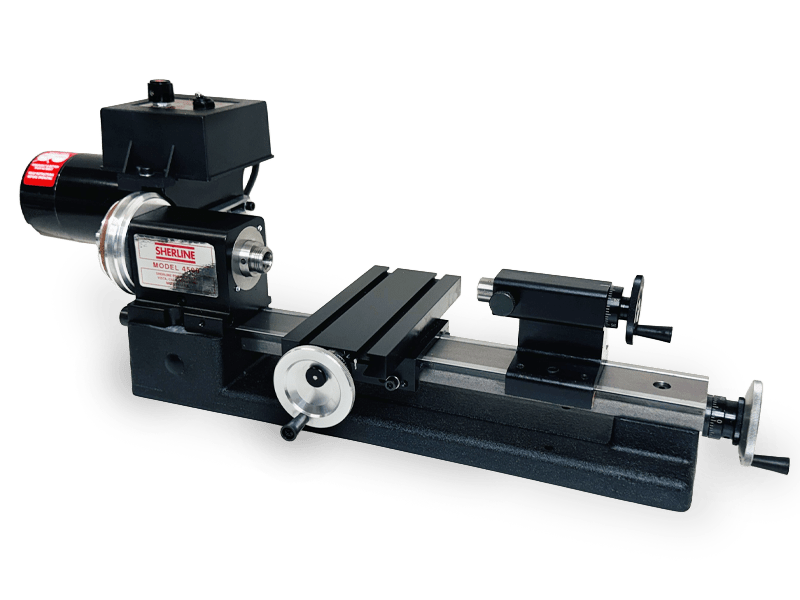

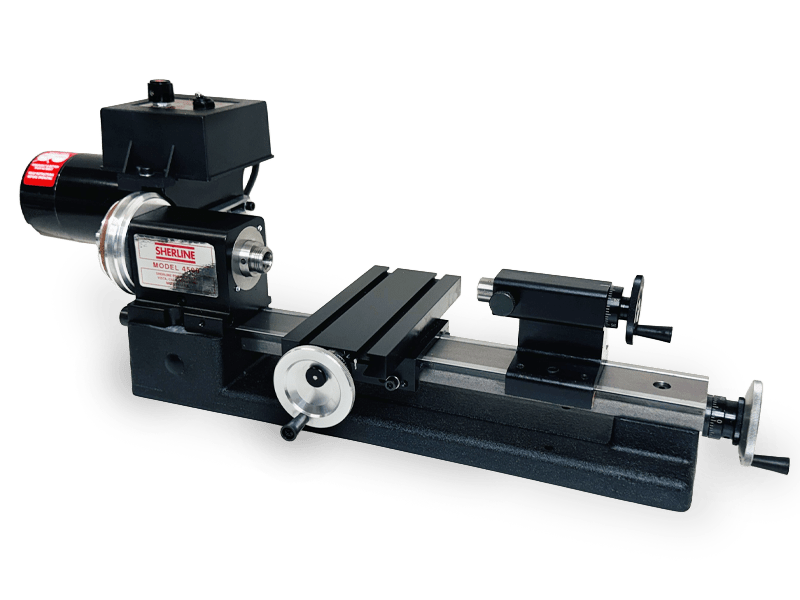

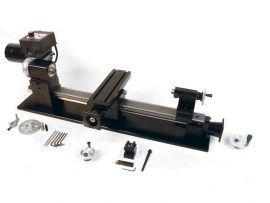

- 15″ (381 mm) steel bed giving 8″ (203 mm) between centers

- Maximum diameter over bed: 3.50″ (90 mm)

- Crosslide travel: 2.75″ × 6.00″ (70 mm × 152 mm)

- 90 V DC motor with electronic speed control – continuously variable 70–2,800 RPM (no belt changes required)*

- DRO handwheels on leadscrew and crosslide

- DRO (Digital Readout) – precise, repeatable positioning, improving accuracy over handwheel-only control

- DRO readout box, DRO-compatible handwheels / encoder setup

- Pulleys, drive belt, faceplate, lathe dog

- Two dead centers

- Three hex keys

- Standard tool post

- Sharpened high-speed steel cutting tool

- Grounded 3-wire power cord (8 ft)

- Instruction manual

- CNC-ready with factory-installed stepper motor mounts (X and Z axes)

- Turns parts up to 3.5″ (90 mm) diameter over the bed

- 15″ (381 mm) bed provides extended travel for longer workpieces

- 6″ (152 mm) crosslide for increased tool reach

- Precision-machined dovetail slides with adjustable gibs and backlash

- High-accuracy spindle and headstock used across all Sherline lathes

- Manual control possible with included handwheels

- Compatible with Sherline’s full line of accessories

- Made in the USA

- Model making and miniatures

- Prototyping and custom part production

- Educational CNC training programs

- Hobbyist and light industrial use

- Adjustable resettable “zero” handwheels: 2.5″ (63 mm) on the leadscrew, 2″ (51 mm) on both the crosslide feed screw and the tailstock - each handwheel has laser-engraved aluminum handwheel collars

- Turns parts up to 3.5″ (90 mm) diameter over the bed and 1.75" (45 mm) over the carriage without riser blocks; with riser blocks, up to 6″ over the bed

- 17″ (430 mm) bed provides extended travel for longer workpieces

- 6″ (152 mm) crosslide for increased tool reach

- Precision-machined dovetail slides with adjustable gibs and backlash

- High-accuracy spindle and headstock used across all Sherline lathes

- Spindle speed: continuously variable from 70 to 2,800 RPM via electronic control (no belt changes required). A second pulley position offers more torque at low RPM if needed

- Rocker-style tool post (replacing the standard post used on shorter lathes)*

- Comes with pulleys, drive belt, faceplate, lathe dog, two dead centers, three hex keys, rocker tool post, a sharpened high-speed steel cutting tool, a grounded 3-wire power cord (8 ft), and instruction manual

- Compatible with Sherline’s full line of accessories

- Made in the USA

- Inch models show position to 0.0005″ (three and a half decimal places)

- Metric models show position to 0.01 mm

- 24″ (610 mm) steel bed giving 17″ (431 mm) between centers

- Maximum diameter over bed: 3.50″ (90 mm)

- Crosslide travel: 2.75″ × 6.00″ (70 mm × 152 mm)

- 90 V DC motor with electronic speed control - continuously variable 70–2,800 RPM (no belt changes required)*

- DRO handwheels on leadscrew and crosslide

- Rocker-style tool post included

- DRO (Digital Readout) - precise, repeatable positioning, improving accuracy over handwheel-only control

- DRO readout box, DRO-compatible handwheels / encoder setup

- Pulleys, drive belt, faceplate, lathe dog

- Two dead centers

- Three hex keys

- Rocker tool post

- Sharpened high-speed steel cutting tool

- Grounded 3-wire power cord (8 ft)

- Instruction manual

- CNC-ready with factory-installed stepper motor mounts (X and Z axes)

- Turns parts up to 3.5″ (90 mm) diameter over the bed

- 17″ (430 mm) bed provides extended travel for longer workpieces

- 8″ (200 mm) crosslide for increased tool reach

- Precision-machined dovetail slides with adjustable gibs and backlash

- High-accuracy spindle and headstock used across all Sherline lathes

- Manual control possible with included handwheels

- Compatible with Sherline’s full line of accessories

- Made in the USA

- Model making and miniatures

- Prototyping and custom part production

- Educational CNC training programs

- Hobbyist and light industrial use

- A powerful 90V DC motor with electronic speed controller

- 10″ base with laser-engraved scales

- Brass leadscrew cover that keeps chips off the rear of the Y-axis leadscrew

- 2.75″ (70 mm) x 13.0″ (330 mm) table with two T-slots

- Standard handwheels:

- (2) 1-5/8″ (41 mm) handwheels on the X- and Y-axes

- (1) 2-1/2″ (63 mm) handwheel with thrust bearings on the Z-axis

- All with laser-engraved aluminum collars

- Pulleys, drive belt, three hexagonal keys, spindle bars, gib removal tool, eight-foot three-wire power cord, and instruction manual

- Oil reservoirs on the X/Y axes and the Z axis help keep critical parts lubricated. These were initially developed for CNC machines that run constantly for hours on end but can benefit manual machines as well

- Inch models show position to 0.0005″ (three and a half decimal places)

- Metric models show position to 0.01 mm

- Powerful 90V DC motor with electronic speed control

- 10″ base with laser-engraved scales

- Brass leadscrew cover that keeps chips off the rear of the Y-axis leadscrew

- 2.75″ (70 mm) x 13.0″ (330 mm) table with laser-engraved scales and two T-slots

- 1.235″ headstock spacer block

- Digital readout box with LCD display, RPM sensor, power supply, cables, stand, and all necessary mounting hardware. No hole drilling is required to mount.

- DRO handwheels that can be reset to zero electronically with the push of a button on the DRO display box.

- (2) 2″ (51 mm) DRO handwheels on X- and Y-axes

- (1) 2-1/2″ (63 mm) DRO handwheel on Z-axis

- All with laser-engraved aluminum collars

- ¼” Drill Chuck w/ key, #1 Morse arbor with drawbolt

- Pulleys, drive belt, three hexagonal keys, spindle bars, gib removal tool, eight-foot three-wire power cord, and instruction manual

- Oil reservoirs on the X/Y axes and the Z axis help keep critical parts lubricated. These were initially developed for CNC machines that run constantly for hours on end but can benefit manual machines as well

- A powerful 90V DC motor with electronic speed controller

- 10″ base

- Brass leadscrew cover that keeps chips off the rear of the Y-axis leadscrew

- 2.75″ (70 mm) x 13.0″ (330 mm) table with laser-engraved scales and two T-slots

- Standard handwheels that can be mounted to the end of the stepper motors to maintain manual control when needed:

- (2) 2″ (51 mm) handwheels on X- and Y-axes

- (1) 2-1/2″ (63 mm) handwheel on Z-axis

- All with laser-engraved aluminum collars

- NOTE: CNC-ready machines cannot be operated manually unless double-shaft stepper motors are installed.

- Pulleys, drive belt, three hexagonal keys, spindle bars, gib removal tool, eight-foot three-wire power cord, and instruction manual

- Oil reservoirs on the X/Y axes and the Z axis help keep critical parts lubricated. These were initially developed for CNC machines that run constantly for hours on end but can benefit manual machines as well

- Precision-machined dovetailed slides with adjustable gibs

- Permanently lubricated spindle bearings

- Adjustable preload, anti-backlash leadscrews

- A high-torque 90V DC motor with electronic speed control

- 12″ base with laser-engraved scales

- Brass leadscrew cover that keeps chips off the rear of the Y-axis leadscrew

- 2.75″ (70 mm) x 13.0″ (330 mm) table with laser-engraved scales and two T-slots

- 1.235″ headstock spacer block

- Resettable, zero-adjustable handwheels:

- (2) 2″ (51 mm) handwheels on X- and Y-axes

- (1) 2-1/2″ (63 mm) handwheel on Z-axis

- All with laser-engraved aluminum collars

- ¼” Drill Chuck w/ key, #1 Morse arbor with drawbolt

- Pulleys, drive belt, three hexagonal keys, spindle bars, gib removal tool, eight-foot three-wire power cord, and instruction manual

- Oil reservoirs on the X/Y axes and the Z axis help keep critical parts lubricated. These were initially developed for CNC machines that run constantly for hours on end but can benefit manual machines as well

- Inch models show position to 0.0005″ (three and a half decimal places)

- Metric models show position to 0.01 mm

- Powerful 90V DC motor with electronic speed control

- 12″ base with laser-engraved scales

- Brass leadscrew cover that keeps chips off the rear of the Y-axis leadscrew

- 2.75″ (70 mm) x 13.0″ (330 mm) table with laser-engraved scales and two T-slots

- 1.235″ headstock spacer block

- Digital readout box with LCD display, RPM sensor, power supply, cables, stand, and all necessary mounting hardware. No hole drilling is required to mount.

- DRO handwheels that can be reset to zero electronically with the push of a button on the DRO display box.

- (2) 2″ (51 mm) DRO handwheels on X- and Y-axes

- (1) 2-1/2″ (63 mm) DRO handwheel on Z-axis

- All with laser-engraved aluminum collars

- ¼” Drill Chuck w/ key, #1 Morse arbor with drawbolt

- Pulleys, drive belt, three hexagonal keys, spindle bars, gib removal tool, eight-foot three-wire power cord, and instruction manual

- Oil reservoirs on the X/Y axes and the Z axis help keep critical parts lubricated. These were initially developed for CNC machines that run constantly for hours on end but can benefit manual machines as well

- A powerful 90V DC motor with electronic speed controller

- 12″ base with laser-engraved scales

- Brass leadscrew cover that keeps chips off the rear of the Y-axis leadscrew

- 2.75″ (70 mm) x 13.0″ (330 mm) table with laser-engraved scales and two T-slots

- 1.235″ headstock spacer block

- Resettable, zero-adjustable handwheels that can be mounted to the end of the stepper motors to maintain manual control when needed:

- (2) 2″ (51 mm) handwheels on X- and Y-axes

- (1) 2-1/2″ (63 mm) handwheel on Z-axis

- All with laser-engraved aluminum collars

- NOTE: CNC-ready machines cannot be operated manually unless double-shaft stepper motors are installed.

- ¼” Drill Chuck w/ key, #1 Morse arbor with drawbolt

- Pulleys, drive belt, three hexagonal keys, spindle bars, gib removal tool, eight-foot three-wire power cord, and instruction manual

- Oil reservoirs on the X/Y axes and the Z axis help keep critical parts lubricated. These were initially developed for CNC machines that run constantly for hours on end but can benefit manual machines as well

- The headstock pivots up to 90° left or right.

- The column bed also rotates side to side up to 90°, enabling angled drilling.

- A specialized knuckle joint allows the column to tilt front to back.

- The ram-style column base can swing side to side up to 90°, offering even greater flexibility.

- Loosening the column cap lets the ram move in and out, providing over 5.5″ of additional travel.

- A powerful 90V DC motor with electronic speed controller

- 14″ base with laser-engraved scales

- Brass leadscrew cover that keeps chips off the rear of the Y-axis leadscrew

- 2.75″ (70 mm) x 13.0″ (330 mm) table with laser-engraved scales and two T-slots

- 2″ column riser block

- Resettable, zero-adjustable handwheels:

- (2) 2″ (51 mm) handwheels on X- and Y-axes

- (1) 2-1/2″ (63 mm) handwheel on Z-axis

- All with laser-engraved aluminum collars

- ¼” Drill Chuck w/ key, #1 Morse arbor with drawbolt

- Pulleys, drive belt, three hexagonal keys, spindle bars, gib removal tool, eight-foot three-wire power cord, and instruction manual

- Oil reservoirs on the X/Y axes and the Z axis help keep critical parts lubricated. These were initially developed for CNC machines that run constantly for hours on end but can benefit manual machines as well

- Inch models show position to 0.0005″ (three and a half decimal places)

- Metric models show position to 0.01 mm

- Powerful 90V DC motor with electronic speed control

- 14″ base with laser-engraved scales

- Brass leadscrew cover that keeps chips off the rear of the Y-axis leadscrew

- 2.75″ (70 mm) x 13.0″ (330 mm) table with laser-engraved scales and two T-slots

- 2″ column riser block

- Digital readout box with LCD display, RPM sensor, power supply, cables, stand, and all necessary mounting hardware. No hole drilling is required to mount.

- DRO handwheels that can be reset to zero electronically with the push of a button on the DRO display box.

- (2) 2″ (51 mm) DRO handwheels on X- and Y-axes

- (1) 2-1/2″ (63 mm) DRO handwheel on Z-axis

- All with laser-engraved aluminum collars

- ¼” Drill Chuck w/ key, #1 Morse arbor with drawbolt

- Pulleys, drive belt, three hexagonal keys, spindle bars, gib removal tool, eight-foot three-wire power cord, and instruction manual

- Oil reservoirs on the X/Y axes and the Z axis help keep critical parts lubricated. These were initially developed for CNC machines that run constantly for hours on end but can benefit manual machines as well

- The headstock pivots up to 90° left or right.

- The column bed also rotates side to side up to 90°, enabling angled drilling.

- A specialized knuckle joint allows the column to tilt front to back.

- The ram-style column base can swing side to side up to 90°, offering even greater flexibility.

- Loosening the column cap lets the ram move in and out, providing over 5.5″ of additional travel.

- A powerful 90V DC motor with electronic speed controller

- 14″ base with laser-engraved scales

- Brass leadscrew cover that keeps chips off the rear of the Y-axis leadscrew

- 2.75″ (70 mm) x 13.0″ (330 mm) table with laser-engraved scales and two T-slots

- 2" column riser block

- Resettable, zero-adjustable handwheels that can be mounted to the end of the stepper motors to maintain manual control when needed:

- (2) 2″ (51 mm) handwheels on X- and Y-axes

- (1) 2-1/2″ (63 mm) handwheel on Z-axis

- All with laser-engraved aluminum collars

- NOTE: CNC-ready machines cannot be operated manually unless double-shaft stepper motors are installed.

- ¼” Drill Chuck w/ key, #1 Morse arbor with drawbolt

- Pulleys, drive belt, three hexagonal keys, spindle bars, gib removal tool, eight-foot three-wire power cord, and instruction manual

- Oil reservoirs on the X/Y axes and the Z axis help keep critical parts lubricated. These were initially developed for CNC machines that run constantly for hours on end but can benefit manual machines as well

- Powerful 90V DC motor with electronic speed control

- 18″ mill base with Y-axis leadscrew protection

- 2.75″ (70 mm) × 18.0″ (457 mm) extended mill table with two T-slots

- 7″ × 13″ tooling plate

- 15″ (63 mm) extended column bed

- Extra-rigid column base

- Resettable, zero-adjustable handwheels:

- (2) 2″ (51 mm) handwheels on X- and Y-axes

- (1) 2-1/2″ (63 mm) handwheel on Z-axis

- All with laser-engraved aluminum collars

- ¼” drill chuck with key, #1 Morse arbor, and drawbolt

- Oil reservoirs on the X-, Y-, and Z-axes

- Pulleys, drive belt, three hex keys, spindle bars, gib removal tool, 8-foot three-wire power cord, and instruction manual

- Inch models show position to 0.0005" (three and a half decimal places)

- Metric models show position to 0.01 mm

- Powerful 90V DC motor with electronic speed control

- 18″ mill base with Y-axis leadscrew protection

- 2.75″ (70 mm) × 18.0″ (457 mm) extended mill table with two T-slots

- 7″ × 13″ tooling plate

- 15″ (63 mm) extended column bed

- Extra-rigid column base

- Digital readout box with LCD display, RPM sensor, power supply, cables, stand, and all necessary mounting hardware. No hole drilling is required to mount.

- DRO handwheels that can be reset to zero electronically with the push of a button on the DRO display box.

- (2) 2″ (51 mm) DRO handwheels on X- and Y-axes

- (1) 2-1/2″ (63 mm) DRO handwheel on Z-axis

- All with laser-engraved aluminum collars

- ¼” drill chuck with key, #1 Morse arbor, and drawbolt

- Oil reservoirs on the X-, Y-, and Z-axes

- Pulleys, drive belt, three hex keys, spindle bars, gib removal tool, 8-foot three-wire power cord, and instruction manual

- A powerful 90V DC motor with electronic speed controller

- 18″ mill base with Y-axis leadscrew protection

- 2.75″ (70 mm) × 18.0″ (457 mm) extended mill table with two T-slots

- 7″ × 13″ tooling plate

- 15″ (63 mm) extended column bed

- Extra-rigid column base

- Resettable, zero-adjustable handwheels that can be mounted to the end of the stepper motors to maintain manual control when needed:

- (2) 2″ (51 mm) handwheels on X- and Y-axes

- (1) 2-1/2″ (63 mm) handwheel on Z-axis

- All with laser-engraved aluminum collars

- NOTE: CNC-ready machines cannot be operated manually unless double-shaft stepper motors are installed.

- ¼” Drill Chuck w/ key, #1 Morse arbor with drawbolt

- Pulleys, drive belt, three hexagonal keys, spindle bars, gib removal tool, eight-foot three-wire power cord, and instruction manual

- Oil reservoirs on the X/Y axes and the Z axis help keep critical parts lubricated. These were initially developed for CNC machines that run constantly for hours on end but can benefit manual machines as well

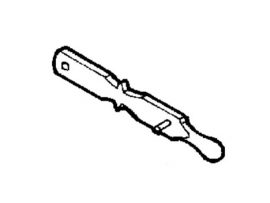

1/4″ HSS Tool Blank

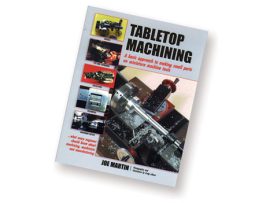

Lathe tools—also known as tool bits—are the cutting tools used for turning, facing, and other operations on a lathe. The most commonly used are high-speed steel (HSS) tools, which are suitable for machining a wide range of materials including wood, plastic, aluminum, brass, and steel. HSS tools maintain their hardness at temperatures up to 1000°F (588°C), making proper depth of cut, cutting speed, and feed rate essential for optimal performance.

One of the key advantages of HSS tools is how easily they can be resharpened using a standard aluminum oxide grinding wheel. Once sharpened, they retain a keen cutting edge through extended use.

Each Sherline lathe comes with a pre-sharpened 1/4″ HSS cutting tool. Pre-ground tool sets—featuring right-hand, left-hand, and boring tools—are also available. However, for long-term savings and flexibility, learning to grind your own tools from blanks is recommended. Custom-shaped tools can be saved for repeat jobs or re-ground for new applications.

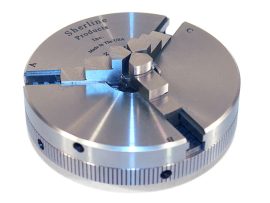

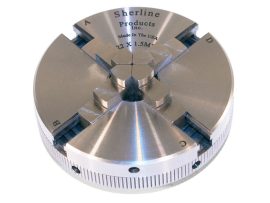

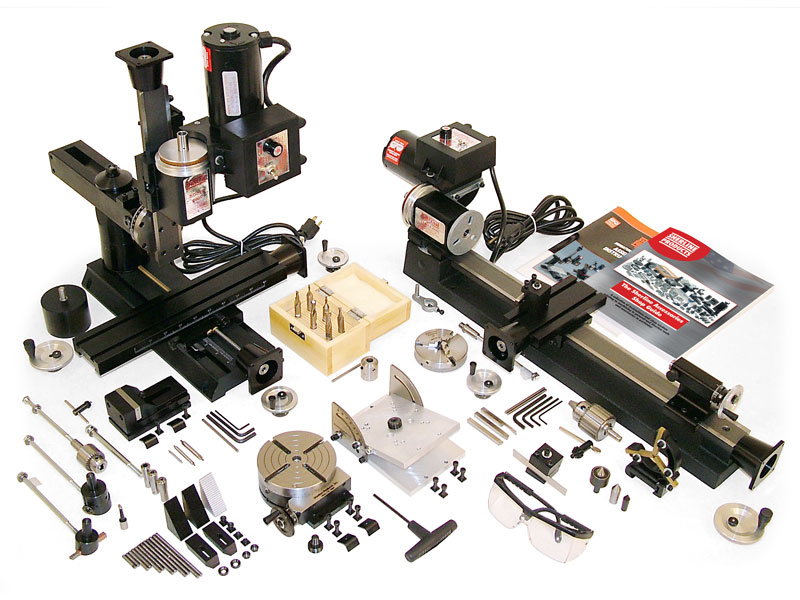

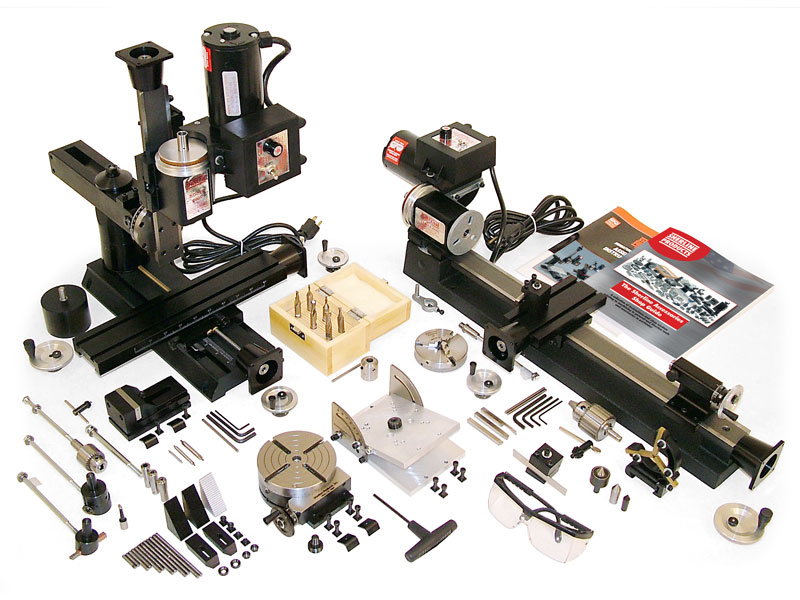

Sherline Precision Jewelers Lathe

Typical Jewelry & Gem-Cutting Applications

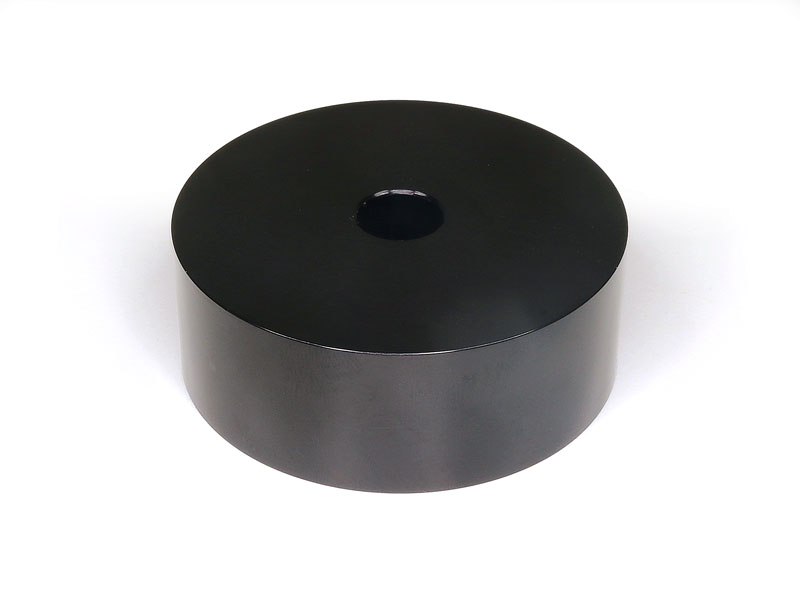

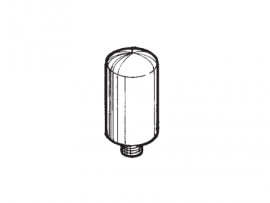

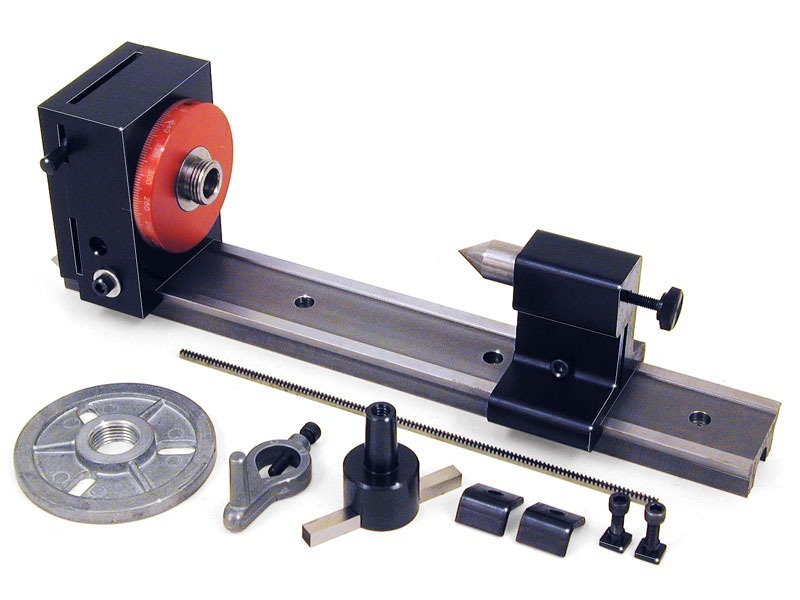

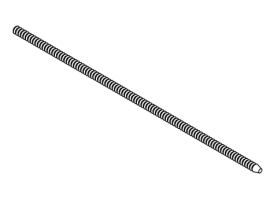

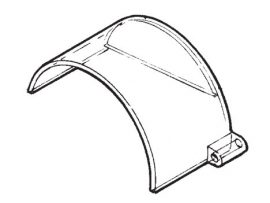

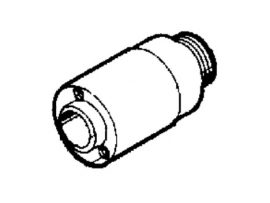

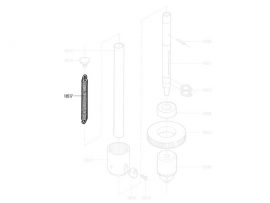

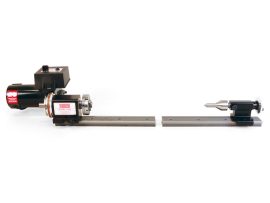

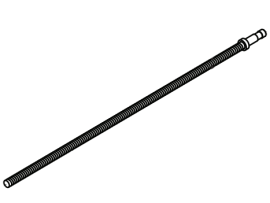

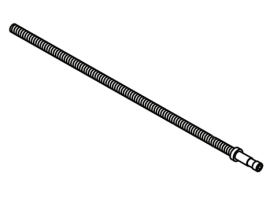

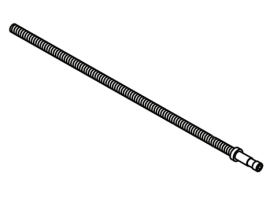

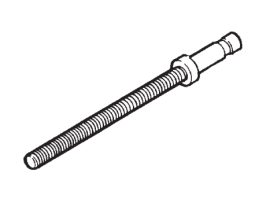

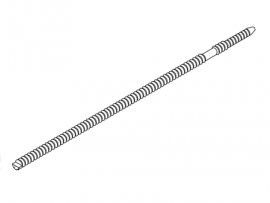

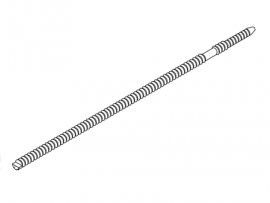

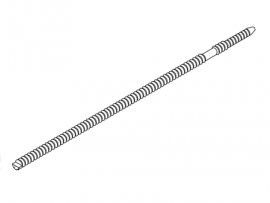

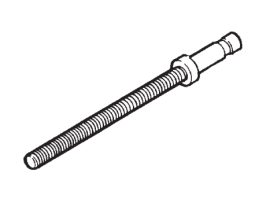

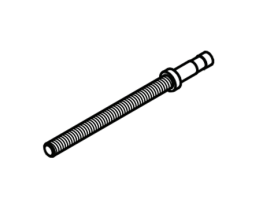

Expanding Ring Mandrel

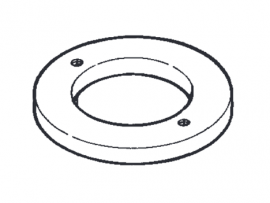

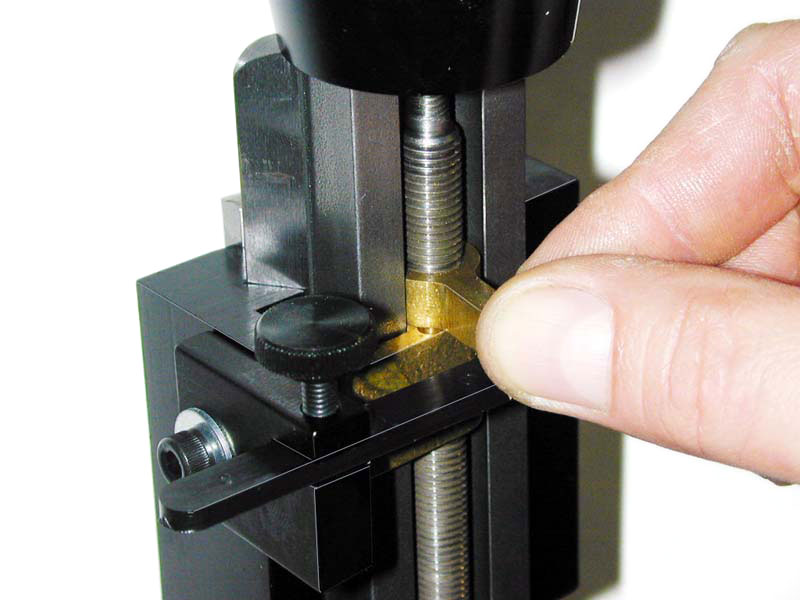

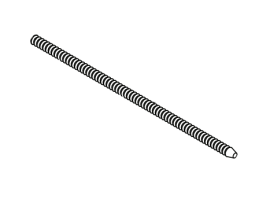

Sherline Products, in collaboration with Bryan D. Drummond (gem cutter and goldsmith), designed this Expanding Ring Mandrel specifically for making and modifying rings on the Sherline lathe.

The mandrel is manufactured from 12L14 steel and features a black oxide finish for rust prevention.

It is designed for use with stepped ring collets manufactured by Ring Tech (Faceting Collets Stepped). These Ring Tech collets are known for their excellent quality and superior design, and, like our machines, are made in the USA.

If you are using a brand of collet that is shorter than the Ring Tech collets, the mandrel includes a spacer washer that fits against the shoulder of the mandrel. This allows shorter collets to be properly positioned at the front of the mandrel.

17″ Ball Screw Benchtop Lathe

Use the selections in the drop-down menus below to configure your machine. (For more information on the configuration options and accessory packages please see the options tab below)

Sherline/Acorn CNC Controller

[icon icon=icon-chevron-down size=14px color=#000 ] Controller Features

Custom control housing includes:[icon icon=icon-chevron-down size=14px color=#000 ] Compatibility & Connection Options

[icon icon=icon-chevron-down size=14px color=#000 ] Software & Conversational CAM

A free version of Centroid CNC12 is included with each Acorn kit for initial setup. However, it is strongly recommended that you purchase the Centroid Acorn “Pro” CNC12 Software License to unlock full conversational CAM (Intercon). Use the options below or visit: CLICK HERE for Acorn “Pro” CNC12 Software License details Intercon Conversational CAM:[icon icon=icon-chevron-down size=14px color=#000 ] Typical Use Cases

DIY Customer[icon icon=icon-chevron-down size=14px color=#000 ] Important Notes for Spindle Control

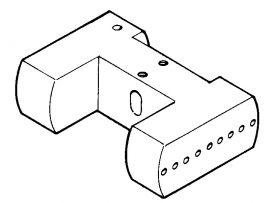

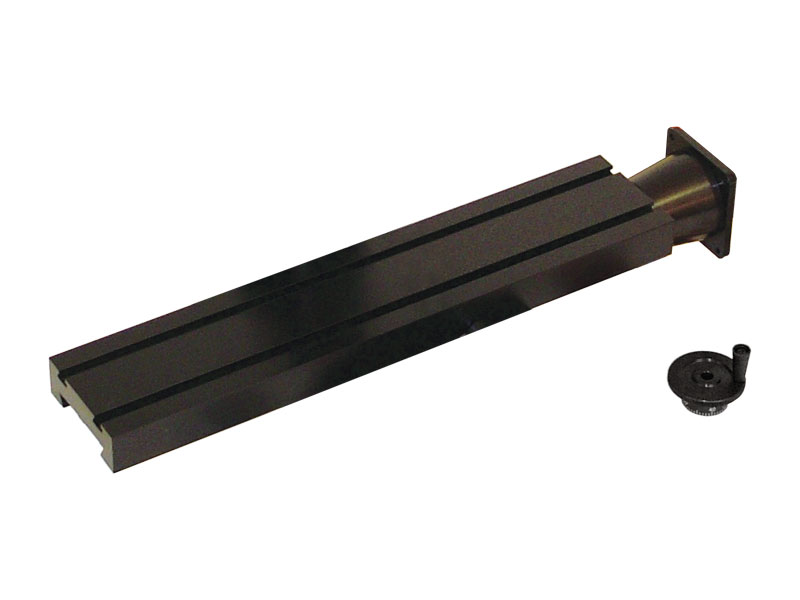

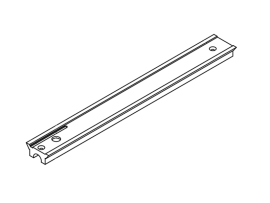

24″ Machined Lathe Base Assembly

3C Step Collet

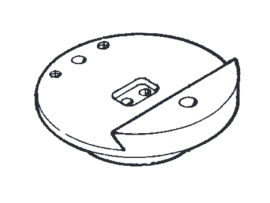

The 3C Step Collet features a 2″ diameter and 1″ depth, making it an excellent addition for machinists using the Sherline 3C headstock. It can be easily machined to size and is specifically designed to hold larger workpieces.

A 1/4″ (6.35 mm) dowel pin is included to provide a gripping surface during the boring process. This helps minimize runout and ensures greater accuracy in the finished bore. Once machined to the desired diameter and depth, the collet effectively becomes a custom chuck—ideal for parts too large for standard 3C collets.

Other head sizes may be available. Please contact Sherline for additional options and pricing.

NOTE: This step collet is designed to grip material only at the face end, not through the collet. Maximum gripping depth is approximately 3/4″ to 7/8″ (19.05 mm to 22.23 mm).

Contact us to inquire about other available step collet head sizes.

55° RH and LH Tool Holders for Inserts w/7° Relief Angle

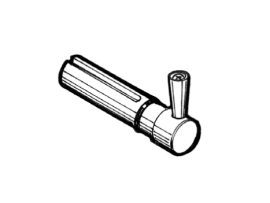

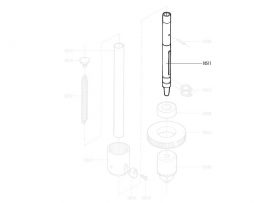

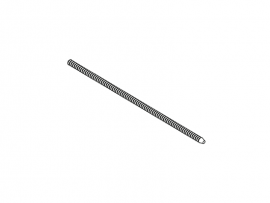

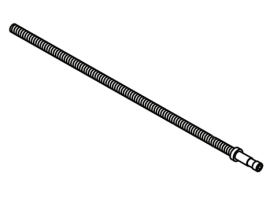

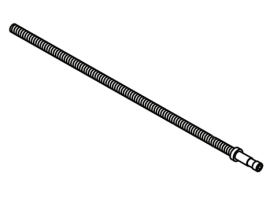

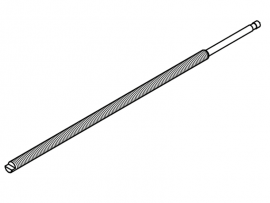

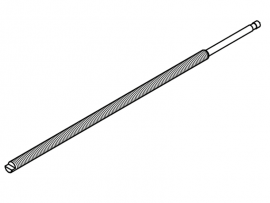

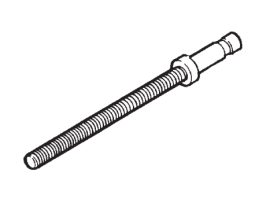

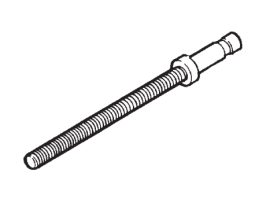

AP Lathe Extended Pivot Pin

AP Mill Extended Pivot Pin

Custom Acorn Controller for Wayne Neilson

SKU: 9400 + 94310 + 9406. This is the Sherline / Acorn CNC Controller (W/O the 4-axis driver box, W/ the Spindle Control Isolator Board, W/ the p/n 94001 External Rotary Encoder, W/ the 2 Speed Motor Pulley for the … Continued

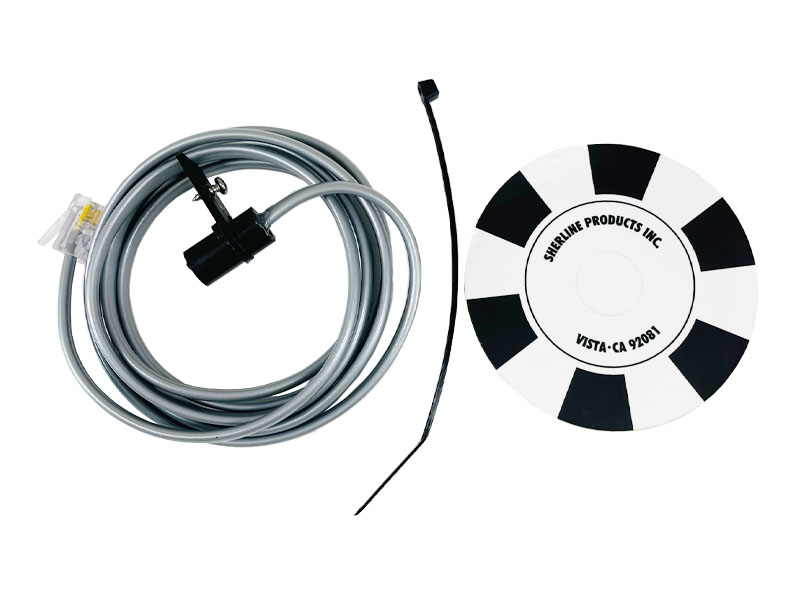

External Incremental Rotary Encoder

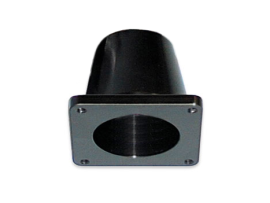

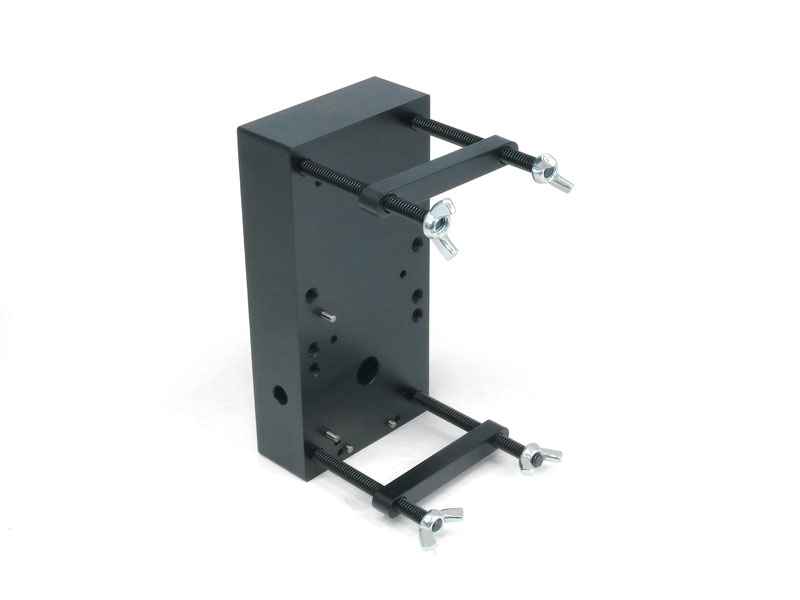

Laser Mount

Laser Upgrade Kit

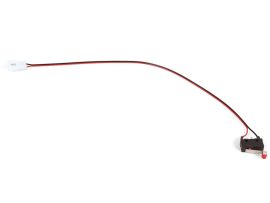

Replacement Homing Sensor

Rotary Table Chuck Lock

Sherline/Criterion Boring Head Arbors

Spindle Control Isolator Board

Accu-Pro Ball Screw Chucker Lathe w/MASSO Touch Controller

CAUTION: The Accu-Pro Mill and Chucker Lathe must be mounted to a work surface, or they will tip when the tables are fully extended.

CONFIGURE YOUR MACHINE: Use the dropdown menu below to add the optional X Package to your Accu-Pro Chucker Lathe. To learn more about the available Accessory Package, click on the Machine Accessories tab below.

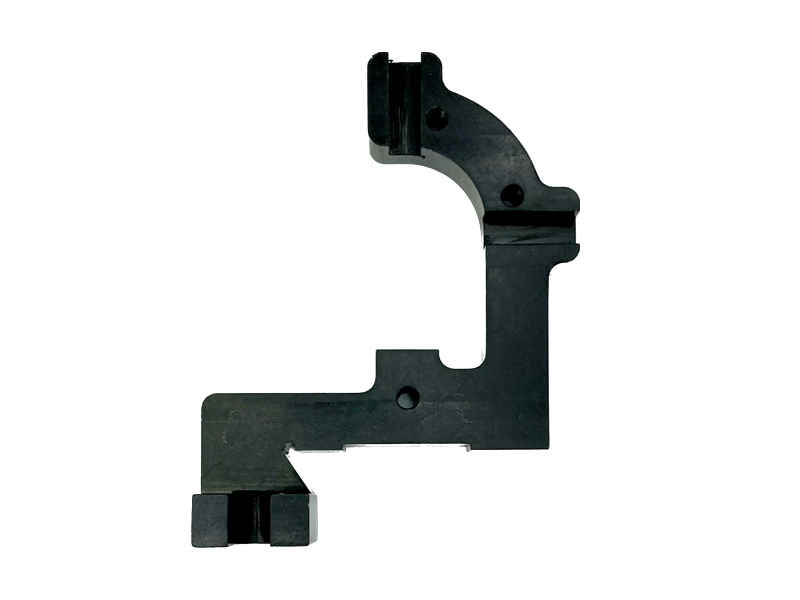

Column Saddle Z-Axis Ball Nut Mount

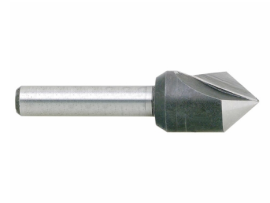

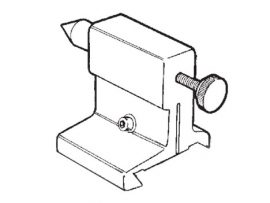

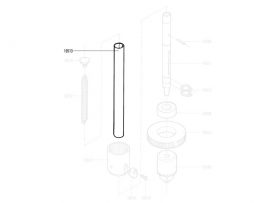

Jeweler Burr Holder

These specialized holders were developed at the request of a jewelry design customer. Similar to our standard end mill holders, they feature a longer body with a tapered end, allowing better visibility of the cutter and improved access for working in cavities.

Each holder includes two Tommy bars and one 1/16" hex key.

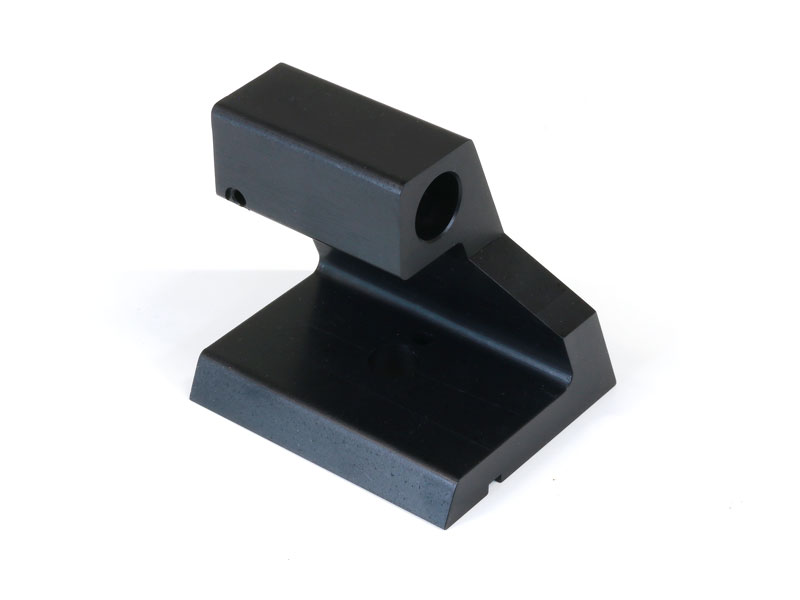

Jeweler DOP Holder

Sherline Products, in collaboration with Bryan D. Drummond (Gem Cutter & Goldsmith), has designed this DOP Holder specifically for securely holding lapidary DOP sticks during gemstone cutting. If you already own one of our machines, the holder is designed to thread directly onto our ¾-16 headstock spindle nose. It will also be an essential accessory for our upcoming gem cutting machines.

Compatible with Ultra Tec® Dops This DOP Holder has been precisely engineered with tolerances and a keyed dop system designed for compatibility with Ultra Tec® brand dops which are used on their faceting machines. Many gem cutters use Ultra Tec equipment for flat faceting, and the keyed dop feature provides secure alignment and ease of use, making it a valuable addition to your setup. Sherline does not manufacture dops, but they can be purchased directly from Ultra Tec. Like Sherline, Ultra Tec products are high-quality and Made in the USA. Shop Ultra Tec Dops Features:

WW Collet Closer Base – Leadscrew Lathe

WW Collet Closer Base – Chucker Lathe

3C Collet Closer base – Leadscrew Lathe

3C Collet Closer base – Ballscrew Lathe

3C Collet Closer base – Chucker Lathe

3C Collet Closer base – Leadscrew Lathe w/Riser

3C Headstock Hard-Stop Kit

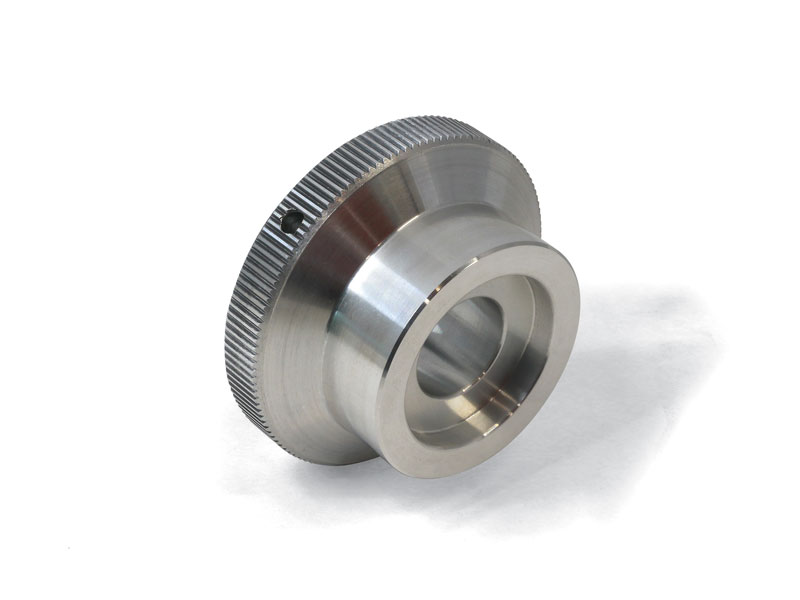

M1 Main Spindle Encoder Pulley-One Speed Pulley

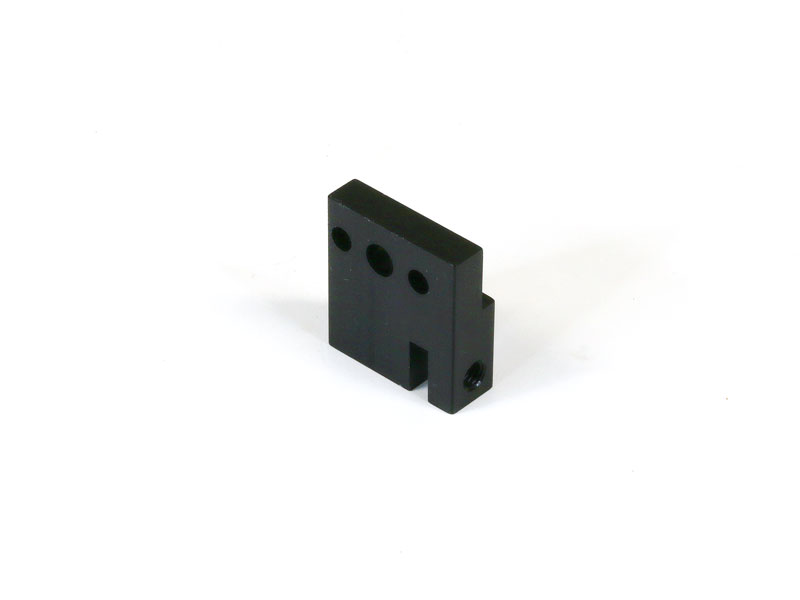

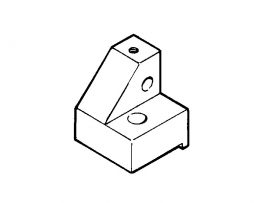

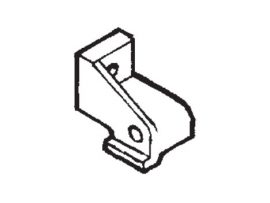

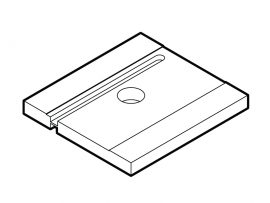

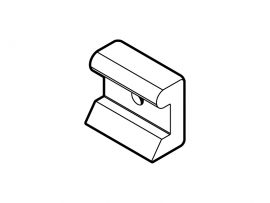

MB Vise Fixture Hard Stop

Hard stop for the MB Vise Fixture with Talon Grips (P/N 3552-35526). What’s included in each set: One vise fixture hard stop One socket head cap screw (not shown)

MB Vise Versagrip Jaw Inserts

These inserts have two serrated sides and bite into the part surface for holding raw material. They are only compatible with the Versagrip top jaws (P/N 35535).

What's included in each set:

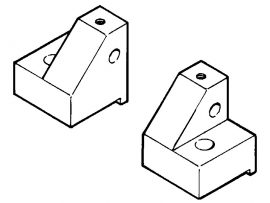

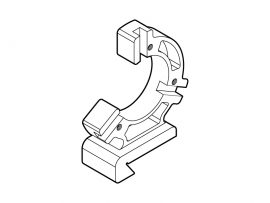

MB Vise Versagrip Top Jaws

The MB Versagrip Top Jaws are used for holding round or oddly shaped stock. These top jaws use the MB Versagrip Vise Jaw Inserts (P/N 35529) made by Mitee-Bite*. You can place the jaw inserts into any insert pockets in the MB Versagrip top jaws to accommodate differently shaped parts.

*NOTE: The MB Versagrip Vise Jaw Inserts are sold separately. What's Included:

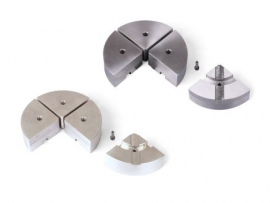

Pie Master Jaws

NOTE: To customers who are buying these jaws for an existing chuck, please measure the width of your current chuck jaws with a pair of mics so we can grind your master jaws to match. State your current jaw width in … Continued

Saddle Nut Oiler

Sherline 3C Collet Spindle Headstocks

Sherline 9/16″ Through-Hole Spindle Headstocks

Sherline ER-16 Spindle Headstocks

Sherline Standard Morse #1 Taper Spindle Headstocks

Accordion Way Cover Set for Ball Screw Mills

Ball Screw Coupling 8 mm – Male Mount

Ball screw coupling with an 8 mm shaft for Accu-Pro machines.

Ball Screw Handwheels

Zero Adjustable Handwheels for ball screw machines. The ball screws are only available in metric, so the numeric graduations on the handwheel dials are 2mm per revolution and .02mm per line.

CNC-Ready Lathe Upgrade Kits

LATHE KITS

Morse #1 Taper Tailstock for Pen Makers

X-axis Limit Switch Mount for Ballscrew Mills & Chucker Lathe

Y-axis Limit Switch Mount for Leadscrew 5400 & Ballscrew Mills & Chucker Lathe

Z-axis Limit Switch Mount for Leadscrew 2000 & 5800, Ballscrew Mills & Leadscrew Lathes

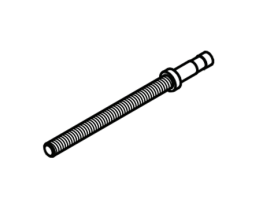

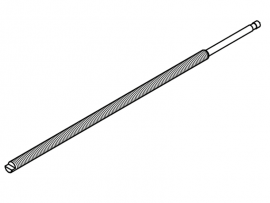

Carbide Insert LH 55° 3/8″ Boring Bar w/2 Flats

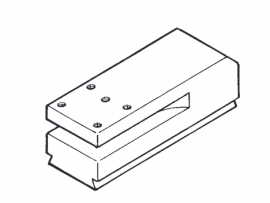

Sherline’s gang-tooling tool post (P/N 5930) was specifically designed for customers converting their Sherline lathe into a chucker-style or gang-tooling lathe. Since most parts produced on a chucker lathe are 1/2" (13 mm) in diameter or smaller, and the center-to-center spacing on our gang-tooling post is 1.5" (38 mm), we identified a practical opportunity: our boring bars can double as both boring and outside diameter (O.D.) turning tools.

To support this dual use, we modified our standard boring bars by adding a second locating flat. This allows them to be mounted with the insert face up or face down, providing flexibility for front- or back-side operations. For example, right-hand 80° and 55° boring bars can now be used effectively on either side of the part (see Figure 1).

These 3/8" diameter boring bars are designed to hold a 2-sided 55° carbide insert, secured with a Torx® screw. Each holder includes an 55° carbide insert and a Torx driver.

See instructions below for additional guidance on using two-flat boring bars with gang tooling setups.

Pro Tip: Consider using the boring bar with the insert face down to help reduce chip buildup on the insert during cutting. This orientation can improve chip evacuation and extend insert life.

FIGURE 1—55° boring bars used as examples. The left-hand tools are used as turning tools, while the right-hand tools are used as boring tools.

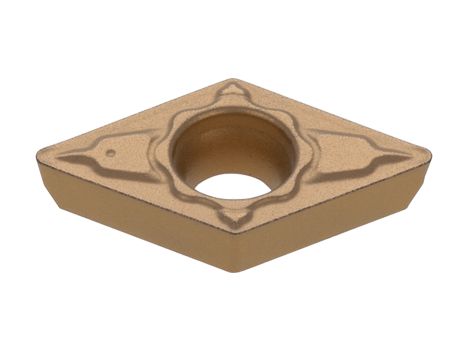

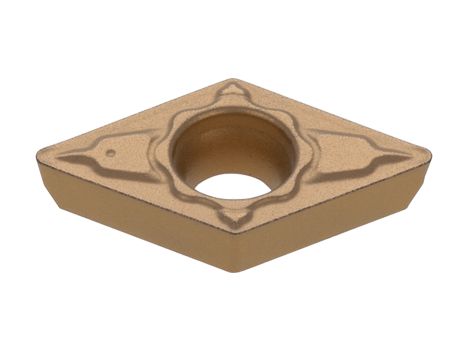

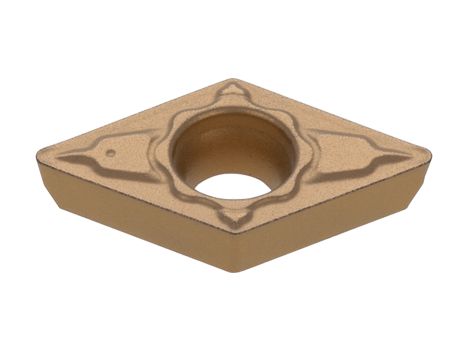

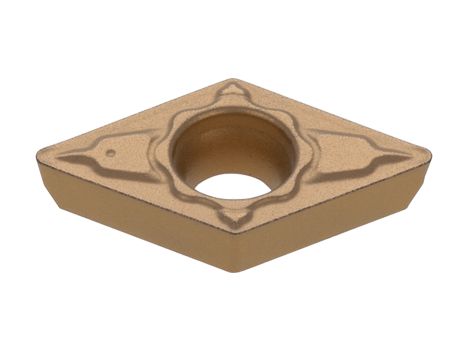

Note: The straight-groove chip breaker shown in some older images is no longer available. Current inserts feature the spider web-style chip breaker as shown here

Carbide Insert LH 80° 3/8″ Boring Bar w/2 Flats

Sherline’s gang-tooling tool post (P/N 5930) was specifically designed for customers converting their Sherline lathe into a chucker-style or gang-tooling lathe. Since most parts produced on a chucker lathe are 1/2" (13 mm) in diameter or smaller, and the center-to-center spacing on our gang-tooling post is 1.5" (38 mm), we identified a practical opportunity: our boring bars can double as both boring and outside diameter (O.D.) turning tools.

To support this dual use, we modified our standard boring bars by adding a second locating flat. This allows them to be mounted with the insert face up or face down, providing flexibility for front- or back-side operations. For example, right-hand 80° and 55° boring bars can now be used effectively on either side of the part (see Figure 1).

These 3/8" diameter boring bars are designed to hold a 2-sided 80° carbide insert, secured with a Torx® screw. Each holder includes an 80° carbide insert and a Torx driver.

See instructions below for additional guidance on using two-flat boring bars with gang tooling setups.

Pro Tip: Consider using the boring bar with the insert face down to help reduce chip buildup on the insert during cutting. This orientation can improve chip evacuation and extend insert life.

FIGURE 1—55° boring bars used as examples. The left-hand tools are used as turning tools, while the right-hand tools are used as boring tools.

Note: The straight-groove chip breaker shown in some older images is no longer available. Current inserts feature the spider web-style chip breaker as shown here

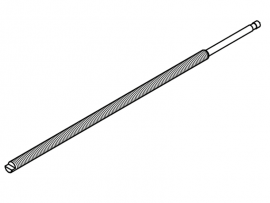

Carbide Insert RH 55° 3/8″ Boring Bar w/2 Flats

Sherline’s gang-tooling tool post (P/N 5930) was specifically designed for customers converting their Sherline lathe into a chucker-style or gang-tooling lathe. Since most parts produced on a chucker lathe are 1/2" (13 mm) in diameter or smaller, and the center-to-center spacing on our gang-tooling post is 1.5" (38 mm), we identified a practical opportunity: our boring bars can double as both boring and outside diameter (O.D.) turning tools.

To support this dual use, we modified our standard boring bars by adding a second locating flat. This allows them to be mounted with the insert face up or face down, providing flexibility for front- or back-side operations. For example, right-hand 80° and 55° boring bars can now be used effectively on either side of the part (see Figure 1).

These 3/8" diameter boring bars are designed to hold a 2-sided 55° carbide insert, secured with a Torx® screw. Each holder includes an 55° carbide insert and a Torx driver.

See instructions below for additional guidance on using two-flat boring bars with gang tooling setups.

Pro Tip: Consider using the boring bar with the insert face down to help reduce chip buildup on the insert during cutting. This orientation can improve chip evacuation and extend insert life.

FIGURE 1—55° boring bars used as examples. The left-hand tools are used as turning tools, while the right-hand tools are used as boring tools.

Note: The straight-groove chip breaker shown in some older images is no longer available. Current inserts feature the spider web-style chip breaker as shown here

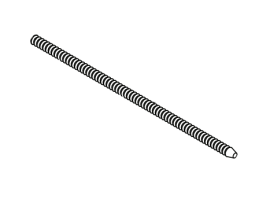

Carbide Insert RH 80° 3/8″ Boring Bar w/2 Flats

Sherline’s gang-tooling tool post (P/N 5930) was specifically designed for customers converting their Sherline lathe into a chucker-style or gang-tooling lathe. Since most parts produced on a chucker lathe are 1/2" (13 mm) in diameter or smaller, and the center-to-center spacing on our gang-tooling post is 1.5" (38 mm), we identified a practical opportunity: our boring bars can double as both boring and outside diameter (O.D.) turning tools.

To support this dual use, we modified our standard boring bars by adding a second locating flat. This allows them to be mounted with the insert face up or face down, providing flexibility for front- or back-side operations. For example, right-hand 80° and 55° boring bars can now be used effectively on either side of the part (see Figure 1).

These 3/8" diameter boring bars are designed to hold a 2-sided 80° carbide insert, secured with a Torx® screw. Each holder includes an 80° carbide insert and a Torx driver.

See instructions below for additional guidance on using two-flat boring bars with gang tooling setups.

Pro Tip: Consider using the boring bar with the insert face down to help reduce chip buildup on the insert during cutting. This orientation can improve chip evacuation and extend insert life.

FIGURE 1—55° boring bars used as examples. The left-hand tools are used as turning tools, while the right-hand tools are used as boring tools.

Note: The straight-groove chip breaker shown in some older images is no longer available. Current inserts feature the spider web-style chip breaker as shown here

3/8-24 Chuck Adapter to Live Center Body w/ 3/8″ straight shank

Mill Column Base-14″ Ball Screw Mill

This mill column base is for the 14″ Sherline ball screw milling machines. It has an additional 1/2″ through-hole to accommodate the larger ball screw and brass cover. It replaces the mill column base on the standard 14″ Sherline mill. … Continued

CNC Controller Board

CNC-Ready Mill Upgrade Kits

Mill Ball Screw XYZ-Axes Retrofit Kit

Mill Ball Screw XY Axes Retrofit Kit

Mill Ball Screw Z-Axis Retrofit Kit

The Mill Ball Screw Z‑Axis Retrofit Kit is an upgrade kit for Sherline milling machines that replaces the standard Z-axis leadscrew with a precision ball screw assembly to reduce backlash and improve smoothness and positional accuracy. It includes a rolled ball screw with BSH nut, stepper-motor coupling and mount, and modified saddle components, and is ready to install with all key parts assembled at the factory.

Why it matters:

• Stronger, smoother Z-axis motion and better CNC performance

• Tight tolerances for increased precision

• Some loss of max travel due to the new saddle design

Interchangeable Jaws

Certain delicate parts require gripping with softer jaw materials. Other operations require chuck jaws that do not transmit particles of rust to the part being held. To accommodate these special circumstances, Sherline now offers 2-piece chuck jaws with interchangeable top jaws made from special materials, and bottom master jaws*. In place of the standard hardened or optional unhardened (“soft”) steel 1-piece jaws, these new top jaws are .600” tall and come in soft materials like Delrin, Teflon, and Nylon, plus harder but non-rusting materials like brass and aluminum. The replaceable top jaws are fastened to the hardened steel bottom jaws with two countersunk socket head screws. They are not stepped so the customer can machine them for custom holding applications. Other materials are available by request.

*Please note that you must purchase the bottom master jaws before you can use the top jaws.

Tall Top JawsWe also offer taller jaws with heights of 1” and 1-1/2”. The tall jaws are made of aluminum and mild steel. These taller jaws were developed for a customer who uses our lathe for custom jewelry design and can be machined to hold custom work, as seen in the photo to the right.

About Top-Jaw Custom Orders See the Top-Jaw Custom Orders tab below to design your own chuck jaws.NOTE: To customers who are buying these jaws for an existing chuck, please measure the width of your current chuck jaws with a pair of mics so we can grind your master jaws to match. State your current jaw width in the comments box below. For first-time buyers who are buying a new chuck with these Master jaws, your jaws will be ground to match your chuck. The prices shown are for the jaws only (new chuck is not included).

Soft Jaws

About the Soft Jaws Set of 3 or 4 soft (unhardened) jaws for the Self Centering and Independent Chucks These are blank jaws, which are used by customers who want to bore or turn them to custom shapes and sizes to fit … Continued

LinuxCNC Computer System with Driver Box

LinuxCNC Computer System without Driver Box

10-32 x 3/8″ Button Socket Head Screw

Drive Type: Internal Hex Finish: Black Oxide Head Style: Button Length: 3/8″ Material: Medium Carbon Steel Thread Type: Fine Diameter: #10

3/8-32 Panel Nut

Wrench Size 1/2″ Thickness 0.098″ Dia/Thread Size 3/8″-32 Finish Zinc Material Low Carbon Steel Thread Type Extra Fine Type Panel Hex Nut

Power Supply for PC

Mfr Part Number: PS-IM400W Features: Comply with Intel ATX12V V1.3 20/24pin connector for M/B Support Intel Pentium 4 & AMD CPU MTBF >50,000 hours at 25°C Input: Input Voltage: 115VAC (90~132VAC); 230VAC (180~264VAC) Input Frequency: 47 ~ 63 Hz Inrush Current: <70A at 230VAC … Continued

Split Bed Pool-Cue Lathe

Accu-Pro Turn Ball Screw Lathe with MASSO Touch Controller

CONFIGURE YOUR MACHINE: Use the dropdown menus below to configure your Accu-Pro Lathe. To learn more about configuring your machine and the available Accessory Package, click on the Machine Accessories tab below.

Accu-Pro VMC Ball Screw Mill with MASSO Touch Controller

CAUTION: The Accu-Pro Mill must be mounted to a work surface, or they will tip when the tables are fully extended.

CONFIGURE YOUR MACHINE: Use the dropdown menus below to configure your Accu-Pro Mill. To learn more about configuring your machine and the available Accessory Packages, click on the Machine Accessories tab below.

12″ Linux CNC Tabletop Mill System w/Ball Screws

12″ Deluxe Tabletop Mill w/Ball Screws – CNC-Ready

Jump to product information

2 to 4-week lead time

14″ Linux CNC Benchtop Mill System w/Ball Screws

14″ Benchtop Mill w/Ball Screws – CNC-Ready

Jump to product information

2 to 4-week lead time

18″ Linux CNC Benchtop Mill System w/Ball Screws

18″ NexGen Benchtop Mill w/Ball Screws – CNC-Ready

Jump to product information

2 to 4-week lead time

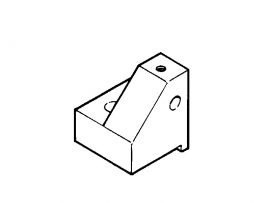

55º LH Insert Holder Body

This is the body only, not a complete assembly. If you need the entire holder, you will need part number 2257

55º RH Insert Holder Body

This is the body only, not a complete assembly. If you need the entire holder, you will need part number 2256.

80º LH Insert Holder Body

This is the body only, not a complete assembly. If you need the entire holder, you will need part number 2254

80º RH Insert Holder Body

This is the body only, not a complete assembly. If you need the entire holder, you will need part number 2253

Lathe Vertical Milling Column Base

DRO RPM Package

Includes Tachometer Encoder with cable and the Tachometer pickup decal.

DRO Z-Axis Thrust Collar

For use on the mill Z axis or vertical milling column installed on a lathe. If you are using DRO with CNC you will need a DRO thrust collar for each stepper motor.

Mill Column Base – 12″ Ball Screw Mill

Mill Table Assembly

Quick-Change Tool Post Body

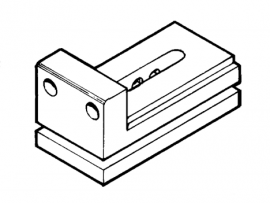

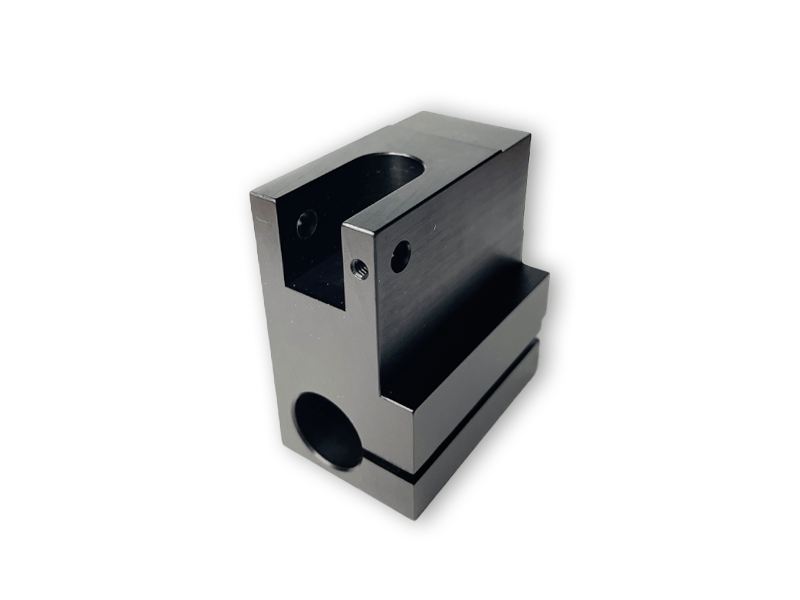

Cutoff Tool Rear-Mounting Block

For those who already own a standard cutoff tool holder, this spacer block will lift the cutoff tool holder the height of the blade, allowing the blade to be mounted upside down and used on the back side of the … Continued

Bump Knurl Tool Holder

Knurling Tool Holder

Sherline's knurling tool adds a professional touch to your parts by embossing knurls into the surface, rather than cutting them. Straight knurls are commonly used on the ends of shafts that will be pressed into other parts, while both straight and diamond knurl patterns are ideal for enhancing grip on handwheels and thumbscrews.

This tool can accommodate diameters up to 1" (25 mm) and features both right and left sides that evenly clamp down on your part as it's turned in the lathe, creating a consistent knurled pattern. It comes with one set of spiral knurls that form a diamond pattern.

Additional sizes of knurls for both diamond and straight patterns are also available in the addition knurls tab below.

Note: This knurling tool is not intended for use with riser blocks.

Quick-Change 3/8″ Square Shank Tool Holder

Quick-Change Carbide Insert Tool Holder

This holder is not included with the Quick-Change Tool Post System (P/N 2250) but is available separately for users who want to take advantage of the enhanced cutting performance offered by carbide tools. The holder includes one 55° carbide insert with two cutting edges, secured by a small screw. A Torx wrench for tightening the screw is also provided.

Like the Quick-Change Tool Post and other dovetailed holders in the system, this inserted tip holder is made from case-hardened steel with a black oxide finish for durability and corrosion resistance.

To learn more about the benefits of using inserted tip carbide tools, CLICK HERE to download a detailed PDF guide.

55° RH and LH Tool Holders w/Carbide Inserts

These tool holders are available individually in right-hand or left-hand configurations, or as a matched pair. Each holder includes a 55° carbide insert, a hold-down screw, and a Torx® key for installation. Designed with a 3/8" square shank, they fit standard 3/8" tool posts, and the insert tip is precisely 0.375" from the base of the holder—an industry-standard dimension.

The 5° offset angle of the cutting tip provides added versatility for certain operations. For example, when the holder is squared with the crosslide, it allows you to turn an outside diameter (O.D.) up to a shoulder and then finish the shoulder by backing the tool out—while maintaining proper tool clearance.

Constructed from case-hardened steel with a durable black oxide finish, these holders are built for long-lasting performance.

Although carbide insert tools are more costly than high-speed steel (HSS) tools, they offer an advantage: when the cutting edge becomes dull or chipped, you can simply rotate the insert 180° to use the second edge—essentially giving you two tools in one.

While HSS tools remain the primary choice for miniature machining due to their low cost, resharpenability, and adaptability for custom form tools, carbide insert tools are invaluable for specific applications. They maintain a sharp edge when cutting hard or abrasive materials, reduce tool wear, and allow for faster machining—reasons why they're widely used in professional machine shops.

Note: Tool orientation is named by the direction the chip exits the tool. A right-hand tool has its cutting edge on the left, and the chip peels off to the right.

Updated Note: The previously used straight-groove chip breaker insert shown in some images is no longer available. All current inserts now come with the spider web-style chip breaker as shown here.

80° RH and LH Tool Holders w/Carbide Inserts

These holders are available individually in right-hand and left-hand configurations, or as a matched pair. Each includes an 80° carbide insert, a hold-down screw, and a Torx® key for installation.

Specifications & Features:

For example, when the holder is squared with the crosslide, it allows you to turn an O.D. up to a shoulder, then finish the shoulder by backing the tool out—while maintaining proper clearance throughout the cut.

Advantages of Inserted Tip Carbide Tools

Although more expensive than high-speed steel (HSS), carbide inserts offer key benefits:

While HSS tools are ideal for general use due to their affordability and ease of resharpening, carbide tools are essential for challenging jobs, which is why they're widely used in professional machine shops.

Note: Tool orientation is based on the direction of chip flow. A right-hand tool has its cutting edge on the left, with chips exiting to the right.

Chip Breaker Update: The previously used straight-groove chip breaker is no longer available. Current inserts now come with the improved spider web-style chip breaker, as shown in the updated product images.

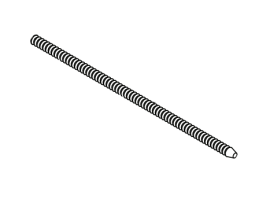

RH 55° and 80° 3/8″ Boring Bars w/Carbide Inserts

These 3/8" diameter boring bars feature a carbide insert secured with a Torx® screw and come complete with a Torx wrench. Choose between:

Each holder measures 3-1/4" long and can bore to a depth of just over 2" when properly secured with two set screws. Manufactured from durable 1144 Stressproof® steel with a black oxide finish, these tools are available individually or as a discounted set.

Why Choose Carbide Insert Tools?

While high-speed steel (HSS) remains common for small machine tools due to its low cost and resharpenability, carbide inserts offer significant advantages in demanding applications:

Although carbide inserts can't be resharpened, their durability and versatility make them a preferred choice in professional machine shops.

Note: The older straight-groove chip breaker insert is no longer available. Current inserts include the spider web-style chip breaker, as shown in the updated images here & here

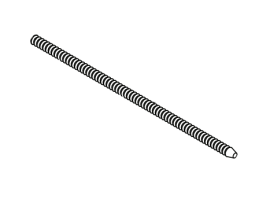

LH 55° & 80° 3/8″ Boring Bars w/Carbide Inserts

These 3/8" diameter boring bars hold a carbide insert secured with a Torx screw. Each comes with either a 2-sided 55° or 80° carbide insert and Torx wrench. The 55° LH boring tool will fit into a 3/4" starting hole. The 80° holder will fit into a smaller 1/2" hole. The 80° holder offers a little more strength for roughing cuts while the 55° insert will cut into sharper corners. The 3-1/4" long holder can bore a hole a little over 2" deep with two fastening screws tightened on it. The holders are made from 1144 Stress-proof steel with a black oxide finish. Available individually.

Left Hand Boring Bars

These LH boring bars are not intended to be used for boring on a standard Sherline lathe, as the spindle is not reversible without electronic modifications. They were developed for a Sherline tool that is now in development where they will be used as a turning tool from the backside with the bit upside down. Watch for the introduction of this new “chucker” lathe soon.

Advantages of Using Carbide Insert Tools

Though relatively expensive, if a cutting edge of a carbide insert becomes dull or chipped, the insert can be removed and rotated 180° to expose two new cutting surfaces, providing, in effect, two tools for the price of one.

The primary method of cutting metal on miniature machine tools is usually with high-speed steel tools as they are inexpensive, easily resharpened and can be ground into "form" tools for special jobs. However, inserted tip carbide tools can be lifesavers for some jobs. Though more expensive and not able to be resharpened, carbide tools hold their cutting edge when cutting exotic metals like stainless steel or titanium or abrasive materials like carbon fiber and can speed up the cutting process. This is why they are used for most cutting tasks in the modern professional machine shop.

NOTE: A tool is named by the direction from which the chip leaves the tool; so a right-hand tool has its cutting edge on the left and the chip peels off to the right.

Tailstock-Spindle Locking Screw

Lathe tailstock-spindle locking screw, 10-24 thread

X-Axis Backlash Nut

X/Z Axis Handwheel Body

Y-Axis Backlash Nut

Y Axis Handwheel Body

Lathe Zero Adjustable Handwheel Upgrade Kit

Includes: 2″ Y Axis Zero Handwheel 2″ X Axis Zero Handwheel 2.5″ Z Axis Zero Handwheel

Mill Zero Adjustable Handwheel Upgrade Kit

Includes the following: 2″ Y-axis Zero Adjustable Handwheel 2″ X-axis Zero Adjustable Handwheel 2.5″ Z-Axis Zero Adjustable Handwheel with thrust bearing

10″ Tabletop Mill XYZ Base – CNC Ready

NOTE: CNC-ready machines cannot be operated manually until stepper motors are installed.

12″ Deluxe Tabletop Mill XYZ Base – CNC Ready

NOTE: CNC-ready machines cannot be operated manually unless double-shaft stepper motors are installed.

14″ 8-Direction Benchtop Mill XYZ Base – CNC Ready

NOTE: CNC-ready machines cannot be operated manually unless double-shaft stepper motors are installed.

14″ 8-Direction Benchtop Mill XYZ Base – DRO

Purpose of the Sherline Benchtop Mill XYZ Bases The Sherline vertical mill can be purchased without the headstock and motor/speed control. This allows lathe owners to swap the headstock and motor/speed control from their lathe to the mill in approximately … Continued

DC motor

Electric Motor Specifications from Manufacturer Type of enclosure: Totally enclosed, non-vented Duty rating: Continuous–10 oz. in. at 6100 rpm, .85 amperes; Intermittent–30 oz. in. at 5500 rpm, 1.75 amperes (5 minutes on / 15 minutes off) Output horsepower: .06 KW (60 W) at … Continued

12″ Deluxe CNC Tabletop Mill System

12″ Deluxe CNC Tabletop Mill System Package A

14″ 8-direction CNC Benchtop Mill System

14″ 8-direction CNC Benchtop Mill Package A

18″ NexGen CNC Benchtop Mill System

18″ NexGen CNC Benchtop Mill System Package A

ER-16 Collet Nut

Saddle Nut Assembly with Ball

4000 Inch to Metric Conversion – Manual

This kit includes everything needed to convert an inch model 4000 lathe to a metric model 4100 lathe

4000 Inch to Metric Conversion – CNC

This kit includes everything needed to convert an inch model 4000 CNC lathe to a metric model 4100 CNC lathe

4100 Metric to Inch Conversion – Manual

This kit includes everything needed to convert a metric model 4100 lathe to an inch model 4000 lathe

4100 Metric to Inch Conversion – CNC

This kit includes everything needed to convert a metric model 4100 CNC lathe to an inch model 4000 CNC lathe

4400 Inch to Metric Conversion – Manual

This kit includes everything needed to convert an inch model 4400 lathe to a metric model 4410 lathe

4400 Inch to Metric Conversion – CNC

This kit includes everything needed to convert an Inch model 4400 CNC lathe to a metric model 4410 CNC lathe

4410 Metric to Inch Conversion – Manual

This kit includes everything needed to convert a metric model 4410 lathe to an inch model 4400 lathe

4410 Metric to Inch Conversion – CNC

This kit includes everything needed to convert a metric model 4410 CNC lathe to an inch model 4400 CNC lathe

5000 Inch to Metric Conversion – Manual

This kit includes everything needed to convert an inch model 5000 manual milling machine to a metric model 5100 manual milling machine.

5000 Inch to Metric Conversion – CNC

This kit includes everything needed to convert an inch model 5000 CNC mill to a metric model 5100 CNC mill

5100 Metric to Inch Conversion – Manual

This kit includes everything needed to convert a metric model 5100 mill to an inch model 5000 mill

5100 Metric to Inch Conversion – CNC

This kit includes everything needed to convert a metric model 5100 CNC mill to an inch model 5000 CNC mill

5400 Inch to Metric Conversion – Manual

This kit includes everything needed to convert an inch model 5400 mill to a metric model 5410 mill

5400 Inch to Metric Conversion – CNC

This kit includes everything needed to convert an inch model 5400 CNC mill to a metric model 5410 CNC mill

5410 Metric to Inch Conversion – Manual

This kit includes everything needed to convert a metric model 5410 mill to an Inch model 5400 mill

5410-CNC Metric to Inch Conversion – CNC

This kit includes everything needed to convert a metric model 5410 CNC mill to an inch model 5400 CNC mill

2000 Inch to Metric Conversion – Manual

This kit includes everything needed to convert an inch model 2000 mill to a metric model 2010 mill

2000 Inch to Metric Conversion – CNC

This kit includes everything needed to convert an inch model 2000 CNC mill to a metric model 2010 CNC mill

2010 Metric to Inch Conversion – Manual

5810 Metric to Inch Conversion – Manual

This kit includes everything needed to convert a metric model 5810 manual milling machine to an inch model 5800 manual milling machine.

2010 Metric to Inch Conversion – CNC

This kit includes everything needed to convert a metric model 2010 CNC mill to an inch model 2000 CNC mill

70° 50TPI Left Hand Spiral Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN Left Hand TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 50 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 50 WHEEL DIAMETER … Continued

70° 50TPI Right Hand Spiral Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN Right Hand TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 50 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 50 WHEEL DIAMETER … Continued

70° 80TPI Left Hand Spiral Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN Left Hand TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 80 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 80 WHEEL DIAMETER … Continued

70° 80TPI Right Hand Spiral Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN Right Hand TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 80 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 80 WHEEL DIAMETER … Continued

90º 20TPI Left Hand Spiral Knurl

STYLE Circular Pitch TOOTH PATTERN Left Hand TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 20 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC LEFT HAND Yes NORMAL CIRCULAR TPI 20 SERIES EP … Continued

90º 20TPI Right Hand Spiral Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN Right Hand TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 20 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 20 RIGHT HAND … Continued

90° 25TPI Left Hand Sprial Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN Left Hand TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 25 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 25 WHEEL DIAMETER 3/16″ … Continued

90° 25TPI Right Hand Sprial Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN Right Hand TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 25 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 25 WHEEL DIAMETER 3/16″ … Continued

90° 35TPI Left Hand Spiral Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN Left Hand TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 35 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 35 WHEEL DIAMETER … Continued

90° 35TPI Right Hand Spiral Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN Right Hand TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 35 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 35 WHEEL DIAMETER … Continued

90° 40TPI Left Hand Spiral Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN Left Hand TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 40 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 40 WHEEL DIAMETER … Continued

90° 40TPI Right Hand Spiral Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN Right Hand TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 40 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 40 WHEEL DIAMETER … Continued

70° 35TPI Straight Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN STRAIGHT TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 35 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 35 SERIES EP WHEEL … Continued

70° 50TPI Straight Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN STRAIGHT TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 50 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 50 SERIES EP WHEEL … Continued

70° 53TPI Straight Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN STRAIGHT TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 53 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 53 SERIES EP WHEEL … Continued

70° 60TPI Straight Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN STRAIGHT TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 60 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 60 SERIES EP WHEEL … Continued

70° 70TPI Straight Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN STRAIGHT TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 70 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 70 SERIES EP WHEEL … Continued

70° 80TPI Straight Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN STRAIGHT TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 80 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 80 SERIES EP WHEEL … Continued

90° 16TPI Straight Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN STRAIGHT TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 16 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 16 SERIES EP WHEEL … Continued

90° 20TPI Straight Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN STRAIGHT TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 20 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 20 SERIES EP WHEEL … Continued

90° 25TPI Straight Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN STRAIGHT TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 25 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 25 SERIES EP WHEEL … Continued

90° 30TPI Straight Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN STRAIGHT TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 30 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 30 SERIES EP WHEEL … Continued

90° 32TPI Straight Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN STRAIGHT TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 32 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 32 SERIES EP WHEEL DIAMETER … Continued

90° 35TPI Straight Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN STRAIGHT TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 35 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 35 SERIES EP WHEEL … Continued

90° 25TPI Male Diamond Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN DIAMOND (MALE) 30° HELIX TOOL MATERIAL High-Speed Steel DIAMETER 1/2″ PITCH 25 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING None HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 25 SERIES EP WHEEL … Continued

90° 40TPI Straight Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN STRAIGHT TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 40 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 40 SERIES EP WHEEL … Continued

90° 41TPI Straight Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN STRAIGHT TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 41 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 41 SERIES EP WHEEL … Continued

90° 47TPI Straight Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN STRAIGHT TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 47 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 47 SERIES EP WHEEL … Continued

.275-40 HSS Spiral Point Tap for WW Collets

Temporarily unavailable until we find a new supplier.

O-Ring