About the Rotary Table Hold-Down Tab

The rotary table hold-down tab (P/N 37210) is a metal plate for mounting the rotary table to a mill table or the right-angle attachment (P/N 3701). The hold-down tab is attached to the rotary table, and then the bottom of this assembly is ground to ensure it will be perfectly flat. The hold-down tabs we have in stock are not ground until assembled to the rotary table base.

Ordering Options for the Hold-Down Tab

Select your option from the Order Options drop-down menu above.

- Factory Replace. Send your rotary table to Sherline*. We mount a new hold-down tab and grind the bottom again. This entails disassembling the rotary table, grinding the bottom with the tab mounted, and reassembling and checking the rotary table.

*NOTES ON SHIPPING:- Do not send anything back to us until we send you an email with instructions on how to return it.

- You must pay for shipping both ways.

- You must package the rotary table very securely. If you have the original shipping box with the piece of wood to mount to the bottom of the rotary table, please use it.

- DO NOT USE packing peanuts; they will only guarantee that your rotary table will be damaged in shipping.

- DO USE a lot of bubble wrap and ensure the rotary table cannot move inside the shipping box.

- Please remove the stepper motor if you have a CNC rotary table before shipping.

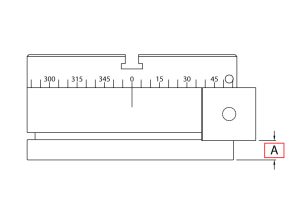

- Customer Measure. Supply us with the thickness of your current hold-down tab in the Comments box above. If you can accurately measure the depth from the bottom of the rotary table to the mounting surface of the worm housing (See dimension A in Figure 1), we can grind a hold-down tab to that thickness.

NOTE: The ground hold-down tab may still be too thick depending on the accuracy of your measurement and the overall flatness and perpendicularity of the worm-housing surface. Once you assemble the hold-down tab, mount the rotary table and see if it sits flat. If not, you will need to sand or machine the hold-down tab to the finished thickness. - Customer Replace. We send you an unground hold-down tab, and you machine it to the correct thickness.