Click the questions below to find the answers.

Don’t see what you’re looking for? Go to our Sherline/MASSO Help page. All the documentation regarding the CNC controller and retrofitting your machine can be found there.

SOFTWARE, PROGRAM, AND CODE QUESTIONS

-

Does MASSO have its own FAQ page?

-

Is there a manual showing all of the keyboard and touchscreen options for MASSO?

-

Is there a quick reference list of the G and M-codes?

-

How do I connect my new Sherline/MASSO controller to my machine?

-

How do I change my password?

-

How do I connect the WiFi?

-

What is the WiFi for?

-

Can I control my spindle speed with the Sherlin/MASSO controller?

-

Can I do threading with the Sherline/MASSO controller?

-

Do I need a particular operating system to run the controller?

-

Can I use any MASSO board to run my Sherline CNC machine?

-

Can I use a touchscreen with the Sherline/MASSO controller?

-

Does MASSO offer software upgrades?

-

Are there instructions on how to program the Sherline/MASSO controller?

-

Does the Sherline/MASSO controller work with the Sherline Chucker Lathe?

-

Can I use a multi-port USB hub connector to use my wired USB mouse and keyboard?

-

I’m experiencing erratic RPM changes. What could be the cause?

-

The time on my MASSO screen is not set to my current time zone. How do I change the time?

-

I have a metric machine, but the MASSO controller is set up for inches. Can I change the unit of measurement to millimeters?

-

Does MASSO have post processors for Sherline machines?

-

Do you have any sample programs for the MASSO controller?

-

Can I control the spindle RPM with the MASSO controller while using the machine in manual mode?

-

I inserted the MASSO flash drive into a computer running Windows software and got a Windows message that said the drive was corrupted. What do I do?

-

Can I enter a tool change position on my MASSO controller?

MECHANICAL AND ELECTRICAL QUESTIONS

-

How do I connect the optical encoder?

-

I have an older CNC machine. Can I add limit switches to it?

-

I already have a Sherline PC with LinuxCNC (or EMC2) on it. Can I use my PC with the Sherline/MASSO controller?

-

Can I add additional relays or accessories to my controller?

-

Can I use a manual pulse generator with the MASSO controller?

-

I’m using the 10,000 RPM pulley. How do I use the Sherline/MASSO Controller to monitor the higher RPM?

-

The 10,000 RPM pulley isn’t syncing properly with the MASSO controller.

-

How do I hook up the axis power cables from the MASSO controller to the stepper motors?

-

The limit switch on my CNC Rotary Table interferes with the angle bracket on my Tilting Angle Table in any position other than 90°. Is there a fix for this?

-

Do you have wiring information for the MASSO optical encoder?

Does MASSO have its own FAQ page?

Yes. It’s listed as MASSO Documentation.

Back to MASSO FAQ Index

Is there a manual showing all of the keyboard and touchscreen options for MASSO?

MASSO doesn’t have a manual for input options, but they do have several pages on their website that are dedicated to this and other controller questions.

MASSO Documentation-Keyboard and Key Shortcuts

Back to MASSO FAQ Index

Is there a quick reference list of the G and M-codes?

Yes. You can find a list of G and M-codes that are supported by MASSO here.

MASSO Documentation-Supported G & M-Codes*

*NOTE: This is a list of all of the G and M-codes that are supported by MASSO. Not all G and M-codes that are on this list will work on Sherline machines. As an example: M04 Spindle CCW is not supported. Codes such as M07, M08, and M09 will work if you have one relay set up for a designated coolant pump or other devices.

How do I connect my new Sherline/MASSO controller to my machine?

Connecting the Sherline/MASSO controller to your CNC machine is a simple, multi-step process. You begin by connecting the controller to the driver box and monitor (not provided), installing the optical encoder, and attaching the limit switches. We have provided complete setup instructions with these documents.

Instructions: Sherline/MASSO CNC Controller Initial Start instructions, and Instructions for Sherline Limit Switches and Mounts

Instructional video link: Setting up Your New Sherline CNC Controller

Back to MASSO FAQ Index

How do I connect the optical encoder?

NOTE: Connecting or disconnecting the connector to the optical encoder or the spindle speed grounding wire must be done with all power OFF! Failure to do so will result in irreparable damage to the optical encoder.

The optical encoder installation is included with the Initial Start instructions beginning on page 7. CLICK HERE for instructions.

Instructional video links: Installing the Optical Encoder, and Setting up the Optical Encoder

Back to MASSO FAQ Index

How do I change my password?

How to Change the MASSO User and Admin Password Instructions

Back to MASSO FAQ Index

How do I connect the WiFi?

The Sherline/MASSO CNC controller comes with a WiFi antenna and module. The MASSO Link software* is designed to work on Windows, macOS, and Linux. To use the Wifi, you must download the WiFi software from MASSO. Click the Instructions link below to learn how to install and download the WiFi software.

Sherline/MASSO WiFi Instructions

Download the MASSO Link Software now

What is the WiFi for?

The WiFi allows you to run your programs with the MASSO controller from another computer or laptop that has your programs on it. Please note that a USB flash drive needs to be connected to MASSO to store these program files.

Back to MASSO FAQ Index

Can I control my spindle speed with the Sherline/MASSO controller?

Yes. The new optical encoder and speed control wiring/software allow for spindle speed control using g-code or MDI input. You will also need to replace the potentiometer on the speed control unit with the new speed control cable for the controller to take control of your DC motor.

Instructions: Retrofitting the Speed Control Unit for the Sherline/MASSO CNC Controller

Instructional video link: Speed Control Retrofit for CNC Controller

Can I do threading with the Sherline/MASSO controller?

Yes. You can do single point threading on the lathe, and you can do thread milling. Our Sherline spindle does not reverse direction; therefore, you cannot do tapping cycles on our lathe or mill.

Back to MASSO FAQ Index

I have an older CNC machine. Can I add limit switches to it?

Absolutely. We have developed limit switch retrofit packages for each axis on each of our machines that include the limit switches, mounting brackets, eccentric triggers, and other mounting hardware (click on the link below for complete parts list details). You just need to tell us what type of Sherline machine and leadscrew you have and what style column you have. You may then connect them to any controller that is configured to work with our limit switches.

Complete parts list: Sherline/MASSO Controller Part Information and Part Numbers

Instructions: Mill Limit Switch Mounting Retrofit Instructions, and Lathe Limit Switch Mounting Retrofit Instructions. Use the following instructions for adding the limit switch eccentric trigger stop for the X-axis on your Ball Screw mill: Retrofitting Your Ball Screw Mill with Limit Switches

Instructional video links: Mill Base Limit Switch Retrofit, and Installing Limit Switches on a Ball Screw Mill

Back to MASSO FAQ Index

I already have a Sherline PC with LinuxCNC (or EMC2) on it. Can I use my PC with the Sherline/MASSO controller?

Yes. If you own a Sherline PC with EMC2 or LinuxCNC on it, and you would like to upgrade to our new MASSO system, click on the instructions Retrofit/Upgrade link below for what you need to do and what you need to purchase. Your PC already has our driver box in it. You can use the driver box in your PC and save a few bucks.

If you prefer to put the CNC circuit board into a dedicated enclosure, click on the Retrofit 2/Upgrade instructions below. You will need to purchase the P/N 87655 Driver box case.

No matter how you decide to use your CNC driver box, you will also need to purchase our P/N 8781 Sherline/MASSO CNC Controller. This kit includes all of the limit switches, limit switch mounts, the optical encoder, and other related cables, etc.

Instructions: Sherline/MASSO Controller Retrofit/Upgrade for Customers who Have a Linux CNC Computer (using the CNC controller board inside the PC)

Sherline/MASSO Controller Retrofit 2/Upgrade for Customers who Have a Linux CNC Computer (using the PC CNC controller board in a new driver box)

Back to MASSO FAQ Index

Do I need a particular operating system to run the controller?

No. The Sherline/MASSO controller is a stand-alone system. You need a computer to write your g-code programs. CAD/CAM software is recommended for more complex parts. The CNC programs can be written on a PC, Mac, Linux, or any other system and then you transfer your programs to the controller via a USB flash drive. No more having to use a dedicated operating system like Linux to control your machine. The MASSO controller comes with some “Conversational” programming cycles for Facing, Pockets, and Profiles on the mill and Turning and Threading on the lathe. You can even do some minor program editing directly in the controller interface on short programs.

Back to MASSO FAQ Index

Can I use any MASSO board to run my Sherline CNC machine?

No. The controller board that we have made for us by MASSO is designed specifically for our machines. The software and the wiring configurations are proprietary to Sherline Products. The components and cable connections are not compatible with any stock MASSO board that you buy directly from MASSO.

Back to MASSO FAQ Index

Can I use a touchscreen with the Sherline/MASSO controller?

Using a touch screen with our MASSO board is possible. However, this is a software upgrade that will need to be purchased from MASSO. Here is a link to their site (https://masso.com.au/product/masso-touch-screen-upgrade/). The site also has a list of supported screens. Customers who are interested in this upgrade will need to check the list of supported monitors first.

Back to MASSO FAQ Index

Does MASSO offer software upgrades?

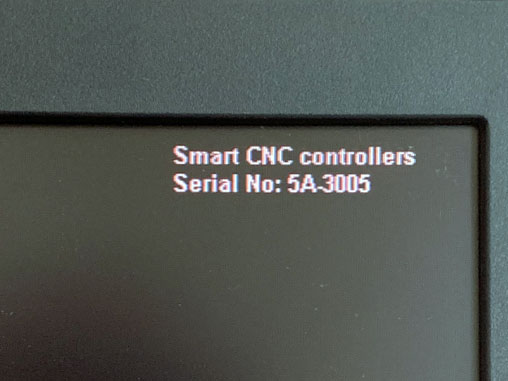

Yes, they do. The software for each MASSO board is “Board Specific.” You need to know what the Board Ser# is for your controller. Each controller comes with a sheet of paper that has the Board Ser#, User Password, and Setup Page Password on it. There is also a sticker on the bottom of the controller base that has the Board Ser# and User Password.

In addition to the above information, if you have lost everything, the Board Ser# will show on your monitor screen (top right corner) when you first turn on the controller (see below).

You will need your SER# to request a software upgrade from MASSO. They will email you the upgrade. Once you have received the upgrade file, follow the instructions on the MASSO software upload Instructions.

Instructional video link: MASSO also has a video that covers this topic, How to update MASSO core software.

Are there instructions on how to program the Sherline/MASSO controller?

Yes. The instructions give a list of supported G- and M-codes, related Sherline video links, and sample programs.

Instructions: Sherline/MASSO Controller Programming

Does the Sherline/MASSO controller work with the Sherline Chucker Lathe?

Yes, and we have created a document that shows you the necessary steps you will need to do in order to set your tool offsets. This document includes additional comments and information that are specific to our CNC Chucker Lathe.

Instructions: Sherline/MASSO Chucker Lathe Tool Calibration

Can I use a multi-port USB hub connector to use my wired USB mouse and keyboard?

No. You cannot use a multi-port USB hub connector in either of the USB ports to operate your old, USB-wired mouse and keyboard. The software in the MASSO controller is designed to take single-source information only from each of the USB ports. A multi-port connector will not work. You must use a wireless USB dongle plugged into the AUX USB port for your peripherals.

Please note that Sherline does not supply the wireless mouse, keyboard, or dongle. There is only one USB port for your mouse and keyboard. Make sure you buy a wireless mouse and keyboard set.

I’m experiencing erratic RPM changes. What could be the cause?

The gap between the optical encoder and the tach spindle pulley RPM sticker may not have sufficient space between them. The original gap setting for the encoder was .080,” but we have found that a wider gap of about .129″ will eliminate random RPM changes. Click on the link below for detailed instructions on how to fix this RPM issue.

Instructions: MASSO Optical Encoder Gap Correction

Back to MASSO FAQ Index

The time on my MASSO screen is not set to my current time zone. How do I change the time?

Go to the MDI button in the lower right-hand corner of the monitor screen and click on it.

In the MDI command window, type the following: Time:xx:xx (where xx:xx is your local time) EX: “Time:08:30” and then press the enter key.

NOTES: Syntax is critical.

- The “T” must be a capital

- There are no spaces between the characters

- MASSO uses a 24-hour time format. For those not familiar with the 24-hour clock, just add 12 hours to the time if it is after 1:00 PM in the afternoon. For example, 3:20 in the afternoon becomes 15:20.

Instructional video link: MASSO 101 – Setting Time

Back to MASSO FAQ Index

I have a metric machine, but the MASSO controller is set up for inches. Can I change the unit of measurement to millimeters?

Yes, you can change the unit of measurement. Click on the link below for the written instructions.

Instructions: MASSO Controller–Changing the Unit of Measurement on the Control Screen

Back to MASSO FAQ Index

Can I add additional relays or accessories to my controller?

Yes. Our Sherline/MASSO controller has one extra connection on the DB15 connector for an additional relay. This relay can be used for a coolant pump, an air cylinder, or any other accessory. Click on the link below for the written instructions.

Instructions: Adding a Relay from the Sherline/MASSO CNC Controller

Back to MASSO FAQ Index

Can I use a manual pulse generator with the MASSO controller?

Yes, but you have to use MASSO’s MPG Pendant. The handheld MASSO MPG Pendant is the perfect addition to your Sherline/MASSO CNC Controller. The MPG pendant is plugged into the DB15 connection that is marked “AUX,” which is specifically for the MPG. Click on the image on the right for a larger view.

The MPG can be purchased directly from MASSO. CNC Pendant Kit.

To learn more about MASSO’s MPG Pendant, visit their MPG Pendant Spec page.

ORDERING NOTE: If you are buying a Sherline/MASSO controller from us and you have purchased an MPG, let us know at the time of purchase, and we will do the wiring changes to your controller board for you.

Instructions: Controller Wiring Changes for the MPG Pendant

Back to MASSO FAQ Index

I’m using the 10,000 RPM pulley. How do I use the Sherline/MASSO Controller to monitor the higher RPM?

The Sherline/MASSO controller is set up to run our standard RPM range of 70 – 2800 RPM. The controller can run your 10,000 RPM pulley. However, you will need to make some changes to the “Spindle” settings on the controller setup page.

Using the 10,000 RPM Pulley with the Sherline/MASSO Controller:

- Adhere the RPM Tach Sticker (P/N 68060) to the Special Tach Washer (P/N 87809)

- Mount it on the 10K Pulley using double-sided tape

- Change the “Spindle” settings on the controller setup page

Instructions: Sherline/MASSO Controller Changes for the 10,000 RPM Pulley

Instructional video link: 10K RPM Pulley Modification

Back to MASSO FAQ Index

The 10,000 RPM pulley isn’t syncing properly with the MASSO controller.

We have recently been informed that there is a problem with the 10,000 RPM pulley working with our MASSO controller.

We found the encoder orientation was fine between the optical encoder headstock spacer (P/N 87816) and the encoder gap gauge (P/N 87813, .129″) when the maximum RPM was 2,800. However, at RPM above 3,000-4,000, the RPM would first increase above the entered value. Then instead of coming down to the entered value, the RPM would go to the maximum of 10,000. The RPM read-out on the MASSO control would read “0,” while the actual RPM was at 10,000.

The solution is a hardware adjustment. Please see the following link on how to fix this issue.

Instructions: Troubleshooting the 10,000 RPM Pulley with the MASSO Controller

How do I hook up the axis power cables from the MASSO controller to the stepper motors?

The axis power cables control the stepper motors and the jog direction of each axis. Use the instruction documentation to make sure you are connecting the power cables to their corresponding stepper motors. The instructions also show the jog direction of each axis.

The axis power cables control the stepper motors and the jog direction of each axis. Use the instruction documentation to make sure you are connecting the power cables to their corresponding stepper motors. The instructions also show the jog direction of each axis.

Instructions: Sherline/MASSO Axis Connections and Axis Directions

Back to MASSO FAQ Index

Does MASSO have post processors for Sherline machines?

Yes. Click the following links for more information.

MASSO Documentation: MASSO CAM Post Processor documents

Autodesk Fusion 360

Back to MASSO FAQ Index

Do you have any sample programs for the MASSO controller?

Yes, we have sample programs for our MASSO controller. Click the links below to find the ones best suited for your needs.

Mill: Sherline/MASSO Controller Programming,

Lathe: MASSO Lathe Program Sample

Crossover Programs (applies to any machine): MASSO Program Header, Tool Change, and End of Program

Back to MASSO FAQ Index

Can I control the spindle RPM with the MASSO controller while using the machine in manual mode?

Yes, you can run the spindle via the controller and use your lathe or mill in manual mode. However, you must do the following:

- Home out the machine with the driver box on and the stepper motors connected.

- Once the machine is homed out, turn off the driver box. Then disconnect the power cords to the stepper motors.

- Turn the driver box back on.

NOTE: The power supply goes into the driver box. Then the power is fed through the driver box and into the controller to power the controller. The system was designed this way so there will only be one power supply needed for both components. Therefore, the controller will not run without having the driver box on. - Now you can use the “F2 Program & MDI” screen to control the spindle speed of the headstock motor and manually move your axis.

VERY IMPORTANT: Before you reconnect your stepper motors, the driver box must be off, or you can damage the driver box (blow the fuse for that axis).

The limit switch on my CNC Rotary Table interferes with the angle bracket on my Tilting Angle Table in any position other than 90°. Is there a fix for this?

Yes, but it involves removing the limit switch and zeroing out the A-axis in the MASSO software. Click the link below to download the PDF instructions.

Instructions: MASSO Rotary Table Limit Switch Interference on the Tilting Angle Table

I inserted the MASSO flash drive into a computer running Windows software and got a Windows message that said the drive was corrupted. What do I do?

EXPLANATION OF A DRIVE FAILURE

MASSO uses the flash drive in a “read-only” mode unless you are writing/editing a G-code file or doing a screen print. Editing within the controller puts the flash drive into a write condition while the file is being saved, but it is immediately returned to a read-only state when the writing is complete. Unplugging the flash drive from MASSO while in the read-only state will not corrupt the flash drive.

In contrast, a PC mounts the flash drive and keeps it in a read/write mode while plugged into the PC for maximum speed. This is why we are instructed to eject the flash drive before unplugging it. If the flash drive is unplugged from a PC while it has files open, it may corrupt the drive and may cause damage, especially if it has not completed updating the critical file allocation tables, etc.

Your MASSO controller may still be able to read the files on the drive, while your PC may see the flash drive as corrupted.

Good practice says to back up the files when you receive the flash drive if you wish to use it for your G-code. Alternatively, put the drive aside as the backup and use another flash drive for day-to-day use. You should also save your G-code to your PC and then copy the files to the USB flash drive. If you have made edits to the G-code within the controller, make sure to copy the files back to your PC.

If you receive a corrupted drive error window and you can no longer read or save to the flash drive on your PC, you will need to replace the flash drive.

If you wish to purchase a MASSO USB flash drive from Sherline, you can place an order for P/N 8762.

REFORMATTING THE FLASH DRIVE

Sometimes the formatting can go bad on these USB drives. Take the steps below to reformat the flash drive.

- Insert the flash drive into a computer.

- Copy the data from your flash drive to a computer, if possible.

- If prompted to reformat, click Yes. If not prompted, you can format the drive using File Explorer.

- Open File Explorer.

- Click on This PC from the left pane.

- Under the “Devices and drivers” section, right-click the flash drive and select the Format option.

- Reformat the USB drive using the setting in the image below.

- In the “Volume label” field, type a label to quickly identify the flash drive in File Explorer.

- Under the “Format options” section, select the Quick format option.

Do you have wiring information for the MASSO optical encoder?

Yes. Click on the link below for the written instructions.

Instructions: Optical Encoder Wiring Diagram

Can I enter a tool change position on my MASSO controller?

Yes. Click on the link below for the written instructions.

Instructions: MASSO Tool Change Position Instructions