What’s New on this Site?

Here’s a summary of the latest things that have been added to or changed. Bookmark this page so you can check back now and then. It’s a quick way to see what has been added since the last time you looked at Sherline’s site. Don’t forget to refresh the page to ensure you get the latest version.

NEW PRODUCT (JANUARY 2026)

Expanding Ring Mandrel

Sherline Products, in collaboration with Bryan D. Drummond (gem cutter and goldsmith), designed this Expanding Ring Mandrel specifically for making and modifying rings on the Sherline lathe.

The mandrel is manufactured from 12L14 steel and features a black oxide finish for rust prevention.

It is designed for use with stepped ring collets manufactured by Ring Tech (Faceting Collets Stepped). These Ring Tech collets are known for their excellent quality and superior design, and, like our machines, are made in the USA. If you buy collets from Ringtech, tell them Sherline sent you.

If you are using a brand of collet that is shorter than the Ring Tech collets, the mandrel includes a spacer washer that fits against the shoulder of the mandrel. This allows shorter collets to be properly positioned at the front of the mandrel.

Jeweler DOP Holder

Sherline Products, in collaboration with Bryan Drummond (Gem Cutter & Goldsmith), have designed this DOP Holder specifically for securely holding lapidary DOP sticks during gemstone cutting. If you already own one of our machines, the holder is designed to thread directly onto our ¾-16 headstock spindle nose. It will also be an essential accessory for our upcoming gem cutting machines.

Key Features:

-

Precision ¼″ dop hole for standard ¼″ dops.

-

3/32″ locating pin for aligning dops with an angle-cut end, ensuring accurate orientation.

-

10-32 set screw provides secure locking of the dop in place.

-

Body constructed from 12L14 steel with electroless nickel plating for rust resistance.

-

Tapered body design for easier dop access and improved visibility of the gemstone during cutting.

3mm Jeweler Burr Holder P/N 2080 – NEW

3/32″ Jeweler Burr Holder P/N 2078

1/8″ Jeweler Burr Holder P/N 2079

Jeweler Burr Holders mount like end mill holders, but are longer with a tapered end. This allows you to see the cutter and also be able to cut down into cavities.

They now come in three sizes.

P/N 2080 holds jeweler burrs with a 3mm shank.

P/N 2078 holds jeweler burrs with a 3/32″ shank.

P/N 2079 holds Dremel tools and other cutters that have a 1/8″ diameter shank, and is available as part of our Z package on our Accu-Pro mill.

NEW PRODUCT (APRIL 2025)

55° RH and LH Tool Holders w/7° Relief Angle

These holders are the same as our 2256 and 2257 with one difference.

Our 2256 and 2257 use a DPMT insert which has an 11° relief angle. These holders use a DCMT insert which has a 7° relief angle.

As with many insert holders and inserts, they change over time. The original DPMT insert that we use with the 2256 and 2257 holders has become less available, and offers less choices for various different chip breaker designs. The DCMT insert is readily available with a wide selection of different insert styles.

NEW PRODUCT (AUGUST 2024)

Sherline/Criterion Boring Head Arbor/Holder P/N 1213/1214

One of our customers suggested this arbor/holder to us. These two boring head arbors are used with the Criterion S-1-1/2″ boring head* on our Sherline milling machines. The Criterion boring head is made in the USA and is well-made and precise, making it a perfect fit for our machines.

The Morse #1 arbor (P/N 12131) mounts directly into the Morse #1 taper on our standard headstock spindle. The End Mill Holder (P/N 12141) threads onto our 3/4-16 Morse #1 spindle thread. Choose the arbor or holder that best fits your needs. Then thread on your Criterion S-1-1/2″ boring head, and you are ready to start boring perfect holes.

*NOTE: The Criterion S-1-1/2″ boring head is not available from Sherline Products and is shown for reference only.

NEW PRODUCT (JULY 2024)

Sherline PLH3D-XT-50 Laser Upgrade Kit P/N 8956

Enhance your Sherline CNC milling machine with the advanced laser upgrade kit from Opt Lasers. This laser kit, in conjunction with our Sherline Laser Mount (P/N 8955), will effortlessly expand your creative and practical capabilities. For projects requiring intricate detail, the PLH3D-XT-50 head, with its 50 μm spot size, delivers unmatched precision, perfect for detailed engravings. These upgrades not only refine your Sherline’s mill performance but also open up new creative possibilities, enabling a wider range of projects.

The PLH3D-XT-50 blue laser can cut and engrave various materials, such as wood, cardboard, rubber, paper, textiles, leather, plastic, balsa, plywood, and many others. It can also mark stainless steel, titanium, and low-heat conductance subtypes of steel.

NEW PRODUCT (APRIL 2024)

Rotary Table Chuck Adapter w/ 1″ x 1″ Blank P/N 37090B

This chuck adapter is similar to our 3/8-16 to 3/4-16 Chuck Adapter (P/N 37090) but without the 3/4-16 thread. Instead of the 3/4-16 thread, it has a 1″ diameter x 1″ long blank that is turned or machined for whatever purpose the user may want, e.g., use it as a locater pin. The adapter is made of 12L14 steel without a finish. It mounts in the center of the Sherline rotary table, as all our chuck adapters do. (The rotary table is shown only for reference and is not included.)

PRODUCT UPDATE (APRIL 2024)

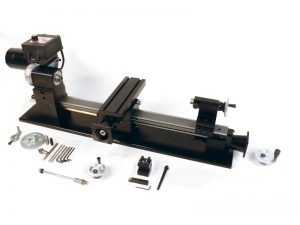

24″ Machined Lathe Base Assembly-2024 Series P/N 44050

Upgrade your old 4400-series 24″ lathe cast base with the new 24″ lathe machined base.

PRODUCT UPDATE (APRIL 2024)

New Benchtop Lathe Bases Are Now in Stock!

Our 4400-series benchtop lathe with the new machined base is now available on our website. All 4400-series lathes are available in manual, DRO, and CNC configurations.

The machined base replaces our current cast base for our leadscrew lathes. The design is based on our ball screw lathe base. The base is wider for better stability and more rigid than our cast base. It is interchangeable with older 17″ benchtop lathes and will be available as a replacement part for the 24″ cast base.

All 4400-Series Benchtop Lathes and Lathe Packages will ship with the new machined base beginning April 2024.

NOTE: Not all of our photos show the new, machined lathe base. Please be patient as we update our photo library.

NEW PRODUCT (DECEMBER 2023)

Sherline/Acorn CNC Controller P/N 9400

Sherline is proud to announce a partnership with Centroid Acorn to offer our CNC customers another option for their CNC machining needs. The Acorn CNC controller is in addition to our MASSO and LinuxCNC controllers. The new Sherline/Acorn CNC Controller is a Plug-and-Play unit with no complex wiring required. It comes in a custom housing with all the necessary connections for DB9, DB25, and 2-wire Molex connectors, as well as Ethernet, power cables, and cooling fans.

We have options to fit your CNC machining needs, whether you are a DIYer who wants to build your own CNC system, if you want to upgrade your current Sherline CNC machines, or if you prefer to start with a complete CNC turnkey system. Visit the Sherline/Acorn CNC Controller product page (P/N 9400) for in-depth details on which options best fit your requirements.

NEW PRODUCT (DECEMBER 2023)

Sherline Embroidered Hats P/N 3000 & 3001

These hats feature our Sherline logo embroidered in bright red on a 100% cotton black corduroy ball cap. They come in two crown profiles with different closure systems: Mid-profile with a 7-position snapback closure and Low-profile with a metal press buckle closure.

NEW PRODUCT (OCTOBER 2023)

Laser Mount P/N 8955

Our Laser Mount (P/N 8955) is now available for sale. With the addition of the laser mount to our accessory line, our customers can now use their milling machine for laser engraving. Some of the primary uses for the laser are cutting gasket material for custom gaskets, engraving part numbers on tools and devices, and engraving pictures and logos. We tested OPT Lasers with the MASSO Touch controller and Centroid Acorn control.

Sherline Products sells an Opt Lasers Upgrade Kit (P/N PLH3D-XT-50). You can purchase a laser from several laser manufacturers.

NEW PRODUCT (MAY 2023)

Headstocks with C5 Bearings

You can now select between Class 3 or Class 5 bearings when purchasing any Sherline headstock.

The C3 bearings have been standard in all of our headstocks for years and have proven reliable. The C5 bearing headstocks come at a higher price than the standard C3 bearings headstocks, but they run smoother, quieter, and cooler than our regular class 3 bearing headstocks and are more suitable in an industrial setting.

Sherline’s new C5 headstocks feature two 20 mm, class 5, lifetime-lubricated ball bearings with an adjustable preload nut. The preload is adjusted at the factory to .0002″ (.005 mm) of endplay. The preload adjustment is controlled by the outer races of the bearings being held apart by the headstock case and the inner races being pulled together by the preload nut. This is appropriate for extended running at speeds of 4000 RPM or less. You may need a slightly looser preload setting of .0003″ for operating speeds up to 10,000 RPM.

NEW PRODUCT (MARCH 2023)

3C Step Collet P/N 1067

The 3C step collet is a great tool addition for those machinists using our Sherline 3C headstock. It is 2″ in diameter and 1″ deep. The step collet can be easily machined and is specially designed to hold larger parts.

NEW PRODUCT (FEBRUARY 2023)

Rotary Table Chuck Lock P/N 3705

This accessory locks the chuck in place when you “thread mount” it to our rotary table. The chuck lock prevents the chuck from unthreading itself during machining operations.

The rotary table chuck lock can also be mounted directly to our mill tables when using our 3- or 4-jaw self-centering chucks (2.5″ and 3.1″ diameters), along with the Chuck to T-slot Adapter (P/N 1187) to secure the chuck to the T-slot on the table.

NOTE: The rotary table and chuck are sold separately and are shown for reference only.

NEW PRODUCT (FEBRUARY 2023)

W12 to 3/4″-16 Clockmaker’s Arbor P/N 2099

Per customers’ requests, we have added a W12 to 3/4″-16 clockmaker’s arbor to our collet-to-thread chuck adapter line. This new arbor fits clockmaker’s lathes (such as the Schaublin) that take W12 collets.

Pneumatic Bar Feeder

P/N 8840

Our bar feeder system was designed to work with our Accu-Pro Turn Ball Screw Chucker Lathe, our standard Chucker Lathe, and our Ball Screw Lathe with the 3C Headstock in conjunction with our 3C Lever Collet Closer. The addition of the bar feeder to our chucker lathe turns our CNC chucker lathe into a fully automated system. You can order it with an optional aluminum base.

The Pneumatic Activation Cylinder Assembly (P/N 8815), which is a part of the Pneumatic Bar Feeder, can be purchased separately for customers who want to open and close the collet pneumatically via G-code without the bar feeder.

The main features of the pneumatic bar feeder include:

- Industrial Components

- Easy to use and operate

- Stock length: 3′

- Stock size: .070″ – .542″ (1 mm – 13 mm)

- Required air pressure: 70 PSI

- Bar feeder is available with or without the aluminum base

- CNC compatible with G-code activation

Click on the Accu-Pro images for product details.

NEW PRODUCT (FEBRUARY 2022)

Accu-Pro Turn Ball Screw Chucker Lathe with MASSO Touch Controller

P/N 696610M

Accu-Pro Turn Ball Screw Lathe with MASSO Touch Controller

P/N 696840M

Accu-Pro VMC Ball Screw Mill with MASSO Touch Controller

P/N 696858M

Our new Accu-Pro machines are designed with industrial shops in mind and are the most powerful Sherline machines to date. These CNC machines offer Sherline reliability combined with a state-of-the-art MASSO G3 touch controller and a 36V power supply. Each machine has ball screws with beefed-up saddles. The line includes an 18″ mill with an 18″ table, a 17″ lathe with an 8″ crosslide, and a chucker lathe with an 18″ base and 18″ crosslide. The MASSO touch controller has a 36V power supply that runs the 36V, closed-loop stepper motors that have a 70 in/min maximum feed rate.

Each Accu-Pro machine has an optical encoder, G-code spindle speed control with threading capability, MASSO homing sensors on all axes, and a USB 4 GB flash drive (With software, machine settings, sample programs, and PDF instructions included.)

The chucker lathe comes with a 3C nickel-plated headstock spindle and a 3C lever collet closer as standard equipment. The lathe and mill have headstock options. For the lathe, choose between our standard #1 Morse headstock or a 3C Collet headstock. For the mill, select between our standard #1 Morse headstock or an ER-16 Collet headstock.

Each machine has accessory package options from which to choose.

- The Accu-Pro mill packages include an MB vise fixture, step block hold-down set, end mill holders, drill chucks, carbide end mill set, fly cutter, 1/8″ shank holder, and a CNC rotary table with a 36V, closed-loop stepper motor. There are four package options from which to choose (not all accessories are included in each package).

- The Accu-Pro chucker lathe package includes a 3/8″ tool post, a 3/8″ rear-side cutoff multi-tool holder, a center drill set, a threading insert tool holder w/insert, RH 80° boring bar w/insert, RH 55° carbide tool holder w/insert, and drill chucks.

- The Accu-Pro lathe package includes a 3.1″ 3-jaw chuck, a live center, a 3/8″ tool post, a 3/8″ rear-side cutoff multi-tool holder, cutoff blade, center drill set, RH 80° boring bar w/insert, RH 55° carbide tool holder w/insert, and a 3/8″ drill chuck.

3/32″ Jeweler Burr Holder P/N 2078

1/8″ Jeweler Burr Holder P/N 2079

Our latest mill tool holders were requested by one of our jeweler customers. They mount like end mill holders, but they are longer with a tapered end, so you can see the cutter and also be able to cut down into cavities.

They come in two sizes.

P/N 2078 holds jeweler burrs with a 3/32″ shank and P/N 2079 holds Dremel tools and other cutters that have a 1/8″ diameter shank.

P/N 2079 1/8″ Jeweler Burr Holder is available as part of our Z package on our new Accu-Pro mill.

NEW PRODUCT (JANUARY 2022)

HEADSTOCK RISER PLATE FOR 13″ CROSSLIDE P/N 1295

Many of our customers have converted their Sherline lathe to a chucker lathe to accommodate gang-tooling setups by replacing the 6″ crosslide with our 13″ mill table. However, the mill table is .270″ thicker than the 6″ crosslide, which puts our tool posts off-center with the headstock spindle. This headstock riser plate matches the additional thickness of the 13″ table, and therefore, all of our standard tool posts will now be on centerline with the headstock.

NOTE: We also have a headstock riser plate for our 8″ crosslide (P/N 1294). The Headstock Riser Plate for 8″ Crosslide is .250″ thick.

Reversible jaw (L), Talon Grip jaw (R)

Versagrip jaw inserts holding an oval part.

NEW PRODUCT (OCTOBER 2021)

SHERLINE MB VISE FIXTURE P/N 3552

Our customers have been asking if we offer a larger mill vise for our mill than our standard milling vise (P/N 3551) for many years. We finally have a new vise fixture design that not only utilizes the entire length of the mill table but can also hold virtually any stock or part shape by offering two different sets of top jaws and clamping inserts.

Our standard Sherline MB Vise Fixture comes with a fixed base plate (P/N 35521) and a movable base plate (P/N 35520), along with two of our top jaws (P/N 35522). You can use this top jaw with either the Talon Grip Vise Jaw Inserts (P/N 35526) made by Mitee-Bite or the Reversible Jaw Inserts (smooth/serrated, P/N 35524) made by Saunders. These top jaws hold square and rectangular stock.

We also offer the MB Versagrip Top Jaws (P/N 35535), used with the same fixed and movable base plates. These top jaws use the MB Versagrip Vise Jaw Inserts (P/N 35529) made by Mitee-Bite. You can place these jaw inserts into any insert pockets in the MB Versagrip top jaws (P/N 35535) to accommodate round material or oddly shaped parts. These jaw inserts are 3/4″ round and can be rotated to match the part shape you wish to hold.

PRODUCT UPGRADE (AUGUST 2021)

NEW DRO CHIP P/N 81705

Our new DRO chip has been tested and is ready for the market. The new chip upgrade allows our Digital Readout to function with our ball screw machines as well as our standard leadscrew machines. While creating this chip, we decided to do some other upgrades based on our customer feedback, like having a Metric display on an Inch machine or having an Inch display on a Metric machine. We believe that this new chip covers all of the possible combinations that our customers have requested.

The new DRO chip has six different modes to choose from based on the machine type, e.g., mill, lathe, leadscrew, or ball screw, and your preference of either inch or metric display on the DRO.

For more detailed information on setting up the modes for DRO, please see the DRO Mode Instructions.

NEW PRODUCT (JANUARY 2021)

3/8″ Rear Side Multi-Tool Holder P/N 5941

5/8″ Rear Side Multi-Tool Holder P/N 5942

These rear-side multi-tool holders were designed to complement our four-position, gang-tooling tool posts. They can be used in conjunction with the gang-tooling tool post, or on their own for our customers who want to convert their Sherline lathe into a “Chucker Lathe” or gang-tooling lathe.

The rear-mount tool holders are slightly taller than their front-side counterparts, P/N 5932 and 5937, allowing the tool to be mounted upside down and used on the backside of the crosslide. The round holes are for holding tools on center (tool not included), like inserted tip tool holders for for P/N 5941, or ER16 collet holders with a 5/8″ shank for P/N 5942.

NEW PRODUCT (OCTOBER 2020)

Rear-Mount Riser Cutoff Holder P/N 1286

Rear-Mount Riser 3/8″ Tool Holder P/N 1287

Riser tool posts are to be used when you have riser blocks installed on your lathe headstock. The rear-mount tool holders are slightly taller than their standard riser counterparts. This allows the tools to be mounted upside down and used on the backside of the crosslide to put the tools on center of the part.

NEW PRODUCT (OCTOBER 2020)

3C E-Collet P/N 10675

Our 3C E-Collet allows you to make your own custom arbors and other part-holding fixtures that will fit our 3C Collet Headstock (P/N 30113). The 3C E-collet has a 1.25″ diameter without a hole or slots. The 3C E-Collet is made from 12L14 steel, so it can be easily machined, and can be case hardened after you have machined it.

NEW PRODUCT (SEPTEMBER 2020)

Chucks with Straight Shaft Arbors

3/8″ Drill Chuck P/N 5938

1/4″ Drill Chuck P/N 5939

These chucks come with a straight shaft arbor (P/N 11850) designed to fit in our multi-tool holder posts with 3/8″ mounting holes (chuck key included). The straight shaft arbor will also work with our 3/8″ insert holder tool post (P/N 7600). The arbor has a 3/8″ diameter straight shaft with a machined flat for holding in the posts.

Multi-tool holders with 3/8″ holes:

NEW PRODUCT (JULY 2020)

Rear-Mount Tool Holder P/N 7604

This tool holder is designed to hold 3/8″ square tools on the “back” side of the part. The rear-mount tool holder is slightly taller than our standard #7600 Tool Post, allowing the tool to be mounted upside down and used on the backside of the crosslide. The round hole is for holding boring tools on center (tools not included).

The photo shows #7600 insert holder tool post, with a threading tool, on the “front” side of the part, while #7604 rear-mount tool holder, with a 55° RH carbide tool, is shown on the “back” side of the part.

NEW PRODUCT (July 2020)

CNC Ball Screw Lathes P/N 6840 (CNC-Ready)

The ball screw lathe design is a reimagined version of our popular 17″ 4400-series lathe. The lathe has a new solid aluminum base, which creates a very rigid assembly, a beefed-up saddle to accommodate the ball screws, a larger 8″ crosslide, and #23 NEMA frame stepper-motor mounts with high-torque couplings.

Ball screw lathes are available with a multitude of options. You can select from a variety of headstocks like ER-16 or 3C, choose a larger 13″ crosslide, select from standard or high-torque stepper motors, configure your CNC driver options, and add accessory packages.

Read our blog entry to learn more about the new ball screw lathe.

NEW PRODUCT (June 2020)

Morse #1 Taper Tailstock for Pen Makers P/N 4112A (4112M), P/N 4412A (4412M)

Pen makers who use our lathes have been bugging us for years to develop a tailstock with a Morse #1 taper. Well, it’s finally here. This tailstock will allow Sherline customers to use Morse #1 taper pen making accessories like pen mandrels and mandrel saver live centers on their lathe. The tailstock assembly includes a brass gib and your choice of a standard handwheel or a zero adjustable handwheel. Inch and metric versions available.

NEW PRODUCT (February 2020)

Reverse Live Center P/N 1192

The reverse live center was designed at the request of our model shipbuilder customers to turn their ship masts. The reverse live center holds the outer diameter of the part inside the concave nose. In contrast, our standard live center locates on a center hole in the middle of the part. The reverse live center point is offered in either steel or hardened steel.

NEW PRODUCT (February 2020)

Tall Top Jaws

We have added new top jaws to our interchangeable jaws collection. These new jaws are 1″ and 1-1/2″ tall, made of aluminum or mild steel, and available in 3- and 4-jaw options. Our standard interchangeable jaws are 5/8″ tall.

The jaws were developed in response to a customer who uses our lathe for jewelry design. The jaws are machinable to hold custom work. We will do custom machining of the jaws for an additional charge. You can contact sherline@sherline.com and send a print of your jaw design to request a quote.

NEW PRODUCT (September 2019)

WW Collet Adapter for 5/8″ Gang Tooling Tool Post P/N 2081

The collet adapter allows the use of WW collets in the 5/8″ Gang Tool Post (not included). Using collets in the Gang-Tool Post means you can hold extremely small drills accurately on center. Drills of only a few thousandths of an inch can easily break if not perfectly centered.

NEW PRODUCTS (July 2019)

Sherline/MASSO CNC Controller w/Driver Box P/N 8780

Sherline/MASSO CNC Controller (no driver box) P/N 8781

We are introducing our new CNC controller, powered by MASSO. The MASSO controller allows you to write your CNC programs on your computer (Windows, Mac, Linux, etc.) and then transfer your programs to the controller via a USB flash drive. It is available with, or without, our 4-axis CNC driver box (P/N 8760).

Learn why we chose MASSO boards to improve our CNC control with a new stand-alone operating system. CLICK HERE.

We have spent the last year working with MASSO getting the features that we need and the features that we want for our CNC machines like:

- Control our spindle speed with g-code

- Optical encoder

- Single-point threading

- Accurate RPM readout

- Limit switches

- Homing ability for each axis

- WiFi communication

- Regular software upgrades

This Sherline/MASSO controller is taking the place of our PC, which is becoming antiquated, and very difficult to find motherboards and very difficult for which to find compatible parts.

NEW SHOP GUIDE, 9th EDITION P/N 5327

Our new, 9th Edition Shop Guides have arrived. They have a fresh cover and 80 additional pages from the previous edition that includes dozens of the latest accessories we have developed over the past five years. It ships with machine packages and is also available on our website (P/N 5327).

NEW WEB PAGE (April 2019)

Many of you may know that we have a specialty page highlighting our tools and accessories designed for Clock & Watchmakers. Well, we recently added a web page that features tips and tool modifications from our customers who are clock and watchmakers.

If you have any examples of things you have done to make your horological projects go easier, send them to us and we will add them to the tip section for all to share. It can be a simple suggestion or special part, but if it makes your life easier, why not share it with others?

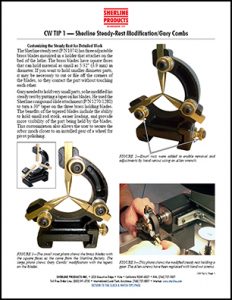

Gary Combs submitted the first Clock and Watchmaking tip highlighting his Sherline Steady-Rest modification.

NEW PRODUCT (April 2019)

Bump Knurling Tool Holder P/N 2275

Add knurling capabilities to your CNC lathe. Our bump knurl tool holder was designed so customers who have CNC machines could add a knurling operation to their program, but it can also be used on a manual lathe. This holder is the same style that is used on full-sized CNC machines. It is held in position using the 3/8″ Insert Holder Tool Post (P/N 7600, not included). We even had noted machinist, Jerry Kieffer, do a demonstration video for our new bump knurl tool. CLICK HERE to watch the video.

NEW PRODUCT! (February 2019)

Straight-Shaft Tool Holders

We have developed a couple of new tool holders for those who are using an ER-16 or 3C headstock on their mills. We have adapted our Fly Cutter and Boring Head to fit in an ER-16 or 3C headstock spindle. These new holders have a straight shaft and are held in the spindle using a 3/8″ collet.* By contrast, our standard tools have a #1 Morse tapered shaft and are held in the 3/4 x 16 headstock spindle with a drawbolt.

Click on the following links to learn more about our new straight-shaft tool holders.

3052S Fly Cutter w/Straight Shaft

3054S Boring Head w/Straight Shaft

*NOTE: Sherline Products does not sell 3/8″ collets used with the ER-16 or 3C headstock spindles. Those are available through Hardinge Inc. or other tool supply sources.

NEW PRODUCTS! (November 2018)

Ball Screw Mills

CLICK HERE to enter the category

Our new ball screw mills can be purchased with 12″, 14″, or 18″ bases, and come in CNC-ready or full CNC configurations. Low friction in ball screws yields high mechanical efficiency compared to other leadscrew alternatives, and efficiencies can range from 70% to 95%.

Key upgrade parts for these ball screw mills include:

- Ball leadscrews

- High-torque stepper-motor couplings

- Ball screw mill saddle (nickel/Teflon plated) for the X/Y-axes

- Vertical milling column saddle for ball screws

- Column saddle Z-axis ball nut mount for the Z-axis

- Linux CNC program disc designed specifically for ball screws

NEW PRODUCT! (November 2018)

Laser-Engraving Pin Chuck Jaws

Our new laser-engraving pin chuck jaws were developed as a result of requests from our laser-marking customers who wanted increased holding diameters. The jaw tops are flat, which gives you a surface to locate your parts against. The short pin jaws (P/N 11414L) can hold round parts up to 3.7″ (94mm) OD and as small as .54″ (13.7mm) ID, while the extended pin jaws (P/N 11413L) can hold parts up to 6″ (153mm) OD and as small as .66″ (16.7mm) ID. The extended jaws are made up of a set of hardened master jaws and extended top jaws.

Each set of jaws has three pinhole locations that hold 3/16″ hard-steel dowel pins, and the pins come in 1″ and 1.5″ lengths, both in sets of three. These thicker 3/16″ pins are for heavier industrial usage.

Click on the following links to learn more about our new laser-engraving pin chuck jaws.*

P/N 11414L Short Laser Pin Chuck Jaws

P/N 11413L Extended Laser Pin Chuck Jaws

*NOTE: These jaws are not designed for machining parts or other uses that require more than finger tight closing pressure to hold the part in the chuck.

NEW PRODUCT! (October 2018)

Electroless Nickel Plated Spindle Headstock P/N 30101

Customers have often asked if we will ever offer a stainless steel spindle in our headstocks. The short answer is, “No.” However, we are now producing a spindle based on our standard headstock that has an Electroless Nickel Plated Spindle with a 3/4″ x 16 T.P.I. This coating offers a hard surface that is rustproof. We believe that this is a cost-effective alternative to using stainless steel. The spindle is available separately, in a headstock, or with a full headstock and motor assembly.

NEW PRODUCT! (June 2018)

Split Bed Pool-Cue Lathe P/N 7000

We are now offering a Split Bed Pool-Cue Lathe, in addition to our custom Extended Bed Lathe. This Split Bed Lathe setup allows custom pool cue makers the ability to adjust the distance between the headstock and the tailstock, depending on the length of the stock being turned, without the expense of ordering a custom extended lathe bed (includes everything you see in the photo). CLICK HERE to learn more about our Custom Lathes and Tools for Turning Pool Cues.

Our updated website has all the great information you have become accustomed to, but it now includes an online store, a new shipping calculator, an improved search function, streamlined menus, and simplified navigation.

Due to the transfer of the online store, you will have to create a new user account and will no longer have access to your prior order history on Sherline Direct. If you have any questions regarding new account creation or your previous order history, we will, of course, be more than happy to help.

NEW PRODUCT! (February 2018)

3C Lever Collet Closer P/N 3025

3C 3C Collet Closer Stop Kit P/N 3024

The 3C lever collet closer was designed to work with our 3C headstock (P/N 30113) and is based on the same design as our standard lever collet closer (P/N 1150). It has separate mounting bases that attach to our standard lathes (P/N 4000 and 4400 models), and our industrial chucker lathe (P/N 6600 models).

Anyone doing repetitive lathe operations on small parts will find this new accessory saves a lot of time when holding parts in a 3C collet.

We also offer an optional material stop (P/N 3024) for the 3C lever collet closer.

Ball Screw X/Y Saddle Lubrication Update

The first few ball screw machines we sent out had an issue with the lubrication system on the X/Y saddle. The oil will immediately drain out of the saddle rather than slowly lubricating the Y-axis dovetail. This video shows how to solve the problem with a simple fix.

CLICK HERE to view the YouTube Video

NEW PRODUCTS! (January 2018)

Ball Screw Upgrades

Mill Z-Axis Ball Screw Retrofit Kit P/N 6800

Mill X/Y-Axes Ball Screw Retrofit Kit P/N 6810

Mill Ball Screw X/Y/Z-Axes Retrofit Kit P/N 6830

We are proud to announce the introduction of ball screw retrofit kits for the X/Y and Z-axes for our mills (Series 5400, 2000, and 5800 models).

The key upgrade parts for this ball screw retrofit kit include ball leadscrews, stepper-motor coupling, the ball screw mill saddle (with nickel/Teflon plate) for the X/Y-axes, a vertical milling column saddle for ball screws and column saddle Z-axis ball nut mount for the Z-axis.

You can order the kits and install them yourself, or you can ship your machine to us for a factory install (installation charges will apply).

These retrofit kits also complement our new High-Torque Stepper Motors (P/N 67127).

Written Instructions:

Ball Leadscrew Customer Notice

Video Instructions:

X/Y-axis Ball Screw Retrofit Install

Retrofitting a Sherline Mill with a Z-Axis Ball Screw Column

NEW WEB PAGE (January 2018)

We have created a new web page devoted to ship modelers. This page highlights the various machines that Sherline offers that can help model makers take their skills to a higher level.

The page also shows typical projects that a show the types of items that can be created using miniature machine tools like wheels, block and tackle, and many other small fittings.

We also feature some master model builders who create museum quality ship models. You can visit their in-depth bios using links to The Miniature Engineering Craftsmanship Museum website.

NEW PRODUCT! (January 2018)

3/8″ Chuck Arbor with 3/8″ Shank P/N 11850

This chuck arbor was designed to mount 3/8″ drill chucks in our multi-tool holder tool posts that have a 3/8″ hole. These tool posts include the following:

NEW PRODUCTS (November 2017)

High-Torque Stepper Motors P/N 67126

Our new, high-torque stepper motor has the same NEMA #23 frame as our standard stepper motor, but it has over 75% more torque. The increased torque means that you can increase your feed rates, and it is also better suited to handle the additional weight of the motor and headstock on our Z-axis.

The high-torque stepper motors can also be used on any Sherline CNC machine. The motor is 2 amps, just like our standard motors, so you can easily upgrade your current Sherline system with the new high-torque motors. (For example, Sherline Complete CNC systems, P/N 8760 CNC 4-axis driver box kit, or any of our CNC upgrade kits.)

ATTENTION: This new high-torque stepper motor requires a special CNC coupling (P/N 671052, sold separately).

NEW PRODUCTS (September 2017)

Nickel-Teflon Coated Rotary Tables with 15/32″ Through-Hole

We have recently released a new set of 4″ rotary tables designed with our industrial users in mind. These industrial versions of Sherline rotary tables have a larger through-hole and a Nickel-Teflon plating on the table surface.

Our industrial customers wanted a rotary table that could hold larger stock and stand up to everyday use. The through-hole on these new rotary tables is 15/32″ (.469″) compared to our standard rotary tables which have a 5/16″ (.316″) through hole, and the Nickel-Teflon coating gives the table a rust-resistant surface that is hard and has added lubrication qualities.

The tables include a chuck adapter (P/N 37097) that has a 3/4-16 thread for the chuck and a 5/8-24 thread for the rotary table, and there is a .6485″ c’bore at the entrance of the 5/8-24 thread which is used to locate the adapter concentric to the rotary table. Like our standard rotary tables, they also include a set of two hold-down clamps and T-nuts for mounting to various surfaces.

These new rotary tables are available in manual (P/N 3710), CNC-ready (P/N 3710-CNC), and full CNC (P/Ns 8711 and 8731) configurations, just like our standard 4″ rotary tables.

Top row (l to r): 5932, 5937

Bottom row (l to r): 5931, 5936

Tools not included, shown for reference only.

NEW PRODUCTS (August 2017)

Multi-Tool Holders

These new multi-tool holders were designed to complement our four position, gang-tooling tool posts (P/N 5930 or P/N 5935). They can be used in conjunction with the gang-tooling tool post, or on its own for our customers who want to convert their Sherline lathe into a “Chucker Lathe” or gang-tooling lathe.

The front-side tool holders hold up to two, round boring tools, and a slot for holding turning, grooving or threading tools. P/N 5932 has (2) 3/8″ holes to hold boring bars, drill chucks, or tool bushings, and a slot to hold a 3/8″ lathe cutting tool with two locking screws for each tool. We also offer a tool post (P/N 5937) that has (2) 5/8″ holes for those wanting to use ER16 collet holders with a 5/8″ shank.

The rear-side cutoff tool holders are similar to the front-side tool holders, but they have a slot for holding a cutoff tool blade (P/N 30860). Using the holder as a rear mounted cutoff tool allows you to use the cutoff tool from the back side of the part. P/N 5931 has 3/8″ holes, and P/N 5936 has 5/8″ holes.

ACCORDION WAY COVER UPGRADE (August 2017)

Mill Accordion Way Cover P/N 5090

Our way cover material has recently been upgraded. The new polypropylene material is more durable and is resilient enough to better withstand the temperature of hot chips. The material itself is more opaque and is 10 mil, versus the clear, 5 mil of the previous version (mil=0.001″).

The upgraded material offers a better value than our previous way covers because it will wear longer, and we are able to offer it without having to raise the price.

NEW WEB PAGE (August 2017)

Our Pool Cue Live Center (P/N 1182PC) has been such a success that we have created a new web page dedicated to Pool Cue Makers. In addition to the live center, there is information on custom pool cue lathes, videos, and related products. You can find the Pool Cue Makers page link in the sidebar menu.

NEW VIDEO (August 2017)

Making Collet Closer Parts with Sherline CNC Machines

Not every job in the machine shop requires the use of large, expensive machines. You can free up some of your more expensive CNC machines by doing small jobs on benchtop CNC lathes and mills like those made by Sherline Products. Sherline’s CNC mills start at under $3,000. Lathes cost even less. This video shows actual parts we make for our lever collet closer (P/N 1150) being made on Sherline CNC machines. You can also find this video posted on our Videos page.

NEW CNC HELP DOCUMENT (August 2017)

LinuxCNC Help for the Sherline Machine CNC System

This document includes sample G and M code, and suggestions for tool holders and setting up your tools. The PDF also includes links to external web CNC documentation and a YouTube Sherline tool video. The direct link to the PDF can also be found on the following page: CNC Instructions

NEW PRODUCT! (June 2017)

Aluminum Replacement Pie Jaws P/N 11454-4P

This replacement set of aluminum pie jaws, P/N 11454-4P, was designed to give our customers the option of pie jaws that are made from a softer material than our P/N 1143-4P steel replacement pie jaws. Because they are aluminum, they can be used with our 1076 chuck. However, we still recommend using them with our 1076C because of the hardness of the nickel and the lubricating properties of the Teflon.

The primary advantage of the aluminum jaws is that the aluminum is easier to machine, and it offers a material that will not scratch or dent softer parts.

NEW SHERLINE LASER DIVISION WEBSITE (May 2017)

Sherline recently launched a new website dedicated solely to our laser marking and scanning products. Each year our machines and accessories are being purchased for use in fields other than for which they were intended. We have developed a number of accessories to aid those in the lasering industries. These accessories include plates, tables, and jaws that help hold parts while being laser engraved or scanned.

NEW PRODUCT! (March 2017)

Pool Cue Live Center P/N 1182PC

We designed this center at the request of some of our customers who use our machines (or modifications of our machines) to make pool cues. They needed a live center with an extended nose, to give them room for their cutters. The extended nose allows them to start cutting from the tip of the pool cue without needing extra material to hold onto.

NEW PRODUCT! (February 2017)

Laser Engraving Tilting Angle Table P/N 3750-LAZ

We designed this tilting angle table for laser engraving because we realize that most laser engraving shops don’t have access to a machine shop that can make special fixtures for their parts. The table includes a dozen steel dowel pins for locating parts, and the bottom half of the holes are tapped so you can use hold-down clamps.

New from dPP Engineering Work with your Sherline controller seamlessly from your Windows®-based Laptop/Desktop USB port (1/6/17)

Use your own laptop or desktop via the USB port with Sherline’s CNC controller P/N 8760

This new controller supports both MACH3 and MACH4 software, whereas previous controllers were dedicated to one software or the other. Moreover, the execution speed is faster than before, especially for MACH4 users. Additional features, such as threading and gear cutting, are easier to implement (spindle speed decoders and PWM are required for the latter).

This USB device is designed specifically for use with CNC machines with existing LPT (parallel printer) port-based control signals input connector. It allows for a quick migration from the LPT to the USB bus. Although small, the device is adjustable and requires no complex knowledge of device programming.

Please visit discount.campus.com for more details regarding the price, features, and requirements of this item.

SHERLINE TO ATTEND 2017 CABIN FEVER EXPO IN LEBANON, PA (1/10/17)

For all of you planning to attend the 2017 Cabin Fever Expo January 14, 15 in Lebanon, PA, please visit Sherline’s booth (N25). We will be demonstrating our largest mill yet, the 5800 NexGen. If you are attending, don’t forget to ask about our Show Special. For more info on the expo, see the Cabin Fever website at www.cabinfeverexpo.com.

NEW PRODUCT! (January 2017)

5/8″ Gang-Tooling Tool Post P/N 5935

Our new 5/8″ gang-tooling tool post is similar to our 3/8″ gang-tooling tool post, but it allows customers to use ER16 collet holders with a 5/8″ shank. Like the 3/8″ holder, it also can also hold up to four tools with a known centerline-to-centerline distance of 1.500″.

NEW PRODUCT! (December 2016)

3/8″ Gang-Tooling Tool Post P/N 5930

Our new gang-tooling tool post was designed specifically for our customers who want to convert their Sherline lathe into a “Chucker Lathe” or gang-tooling lathe. The gang-tooling tool post offers a convenient and accurate way to hold up to four tools with a known centerline-to-centerline distance of 1.500″. This tool post has (4) 3/8″ holes to hold boring bars, drill chucks, or tool bushings with two locking screws for each tool (tools not included).

NEW PRODUCT! (December 2016)

4″ Reverse Rotary Table P/N 3700-OP

The reverse rotary table is perfect for using on the tilting angle table (P/N 3750). The reverse mount allows access to the handwheel from the front of the machine. If you used a standard rotary table in the previously described set-up the handwheel would be mounted facing the backside of the X-axis. It is also available in CNC-Ready configuration, P/N 3700-CNC-OP.

NEW PRODUCT! (December 2016)

Jack-in-a-Box Puzzle Kit P/N J1000

Here’s a fun project that you can make on your Sherline mill that will amaze your friends. When done, a tiny jack is contained inside a cube with a hole in it. How did they get in there? How was it made? Producing the finished cube requires a series of drilling and boring processes explained in the step-by-step illustrated instructions that come with the kit.

Sherline Products is proud to announce its sponsorship of Duro UAS.

Duro builds “eco-drones” like the Harbor AUV, one of the first autonomous underwater vehicles dedicated to urban coastal mapping and environmental data collection. Students will be using a Sherline 2000 mill to make parts for the AUV. To learn more about Sherline’s collaboration with Duro UAS CLICK HERE, or to learn more about Duro UAS visit their website at durouas.com. You can also visit our new Engineering Support page to view more stories about how Sherline Products is being used in other educational and industrial settings.

NEW PRODUCT! (August 2016)

Our latest product is a 2″ Rigid-Column Spacer. These spacers are available in round and rectangular formats for the 2000-series mill and the 5400-series mill column bases with a 2000 ram, respectively. The round spacer on the left is designed to be used in conjunction with the 2000-series mill, while the rectangular spacer is meant to be used with either our Short and Tall 5400 Mill Column Bases with the 2000 Ram. Click the part number for product details on the round spacer P/N 56057 or here for the rectangular spacer P/N 50058.

Now available for Windows 10, 32b and 64b For Windows® users only (6/6/16)

Use your own laptop or desktop via the USB port with Sherline’s CNC controller P/N 8760

New from dPP Engineering is this new USB CNC to LPT motion controller. This product contains a microprocessor which simulates a complete CNC controller program and thus elevates the processing load from the host computer. It is 100% LPT port pin-out compatible. This product works with either Artsoft’s MACH4 CNC software. A similar product works with Artsoft’s MACH3 and UC-CNC. Visit discountcampus.com for more information.

NEW PRODUCT! (May 2016)

3C Collet Headstock P/N 30113

Many of our customers over the years have requested a spindle and collet that would allow larger diameter stock to go through the headstock. With the 3C collet, our customers can now hold stock up to 1/2″ diameter that will pass through the headstock. The 3C Collet Headstock includes a 1″ spindle wrench (shank and collet not included, shown for reference only).

SHERLINE TO ATTEND 2016 DMEDS IN DEL MAR, CA (5/4/16 – 5/5/16)

The DMEDS is the Del Mar Electronics & Design Show. This event is a design and manufacturing show open to the public for electronics, medical and biotech industries located in Southern California with over 65 FREE seminars.

The expo will be held at the Del Mar Fairgrounds, May 4-5, in the Bing Crosby and Exhibit Halls. We will be showing many of our new products and items from our industrial products division. Attendees must register, but admittance is FREE!

For more info on the expo, see the Del Mar Electronics & Design Show web site at www.mfgshow.com.

SHERLINE TO ATTEND 2016 NAMES EXPO IN WYANDOTTE, MI (4/21/16)

For all of you planning to attend the 2016 NAMES Expo April 23-24 in Wyandotte, please visit Sherline’s booth (58-61). We will be demonstrating our largest mill yet, the 5800 NexGen and more. For more info on the expo, see the North American Model Engineering Society web site at www.namesexposition.com/expo.

NEW PRODUCT! (February 2016)

Riser Plate for 8″ Crosslide P/N 1294

We designed the headstock riser plate P/N 12940 at the request of several of our customers who replaced our 6″ crosslide with the thicker 8″ crosslide P/N 60880 (manual) and P/N 67036 (CNC). Most of these customers are using our lathe as a chucker lathe with gang tooling. By using this riser plate, we have raised the headstock to match the additional thickness of the 8″ crosslide. Therefore, all of our standard tool posts will now be on centerline with the headstock.

NEW PRODUCT! (January 2016)

5400 Mill Column Base with 2000 Ram P/N 5640 (Short), P/N 5645 (Tall)

These rigid columns are designed for those who have a 5400-series mill. Each comes with the 2000-series ram and gives the versatility of Sherline’s 2000-series mill column with it’s large work area and seven directions of movement. The tall column provides more Z-clearance.

NEW PRODUCT! (January 2016)

Rigid Mill Column Bases for 2000 Mills P/N 5605 (Short), P/N 5606 (Tall)

For those who want the versatility of Sherline’s 2000/2010 mill column with it’s large work area and multiple directions of movement but have experienced unwanted column rotation during extreme machining loads on the 2000 mill, this new column offers another option. The one-piece column absolutely prevents that from happening, although you do give up the ability to rotate the column ram from side-to-side.

NEW PRODUCT! (November 2015)

NexGen Vertical Mill P/N 5800/5810

Starting in November, 2015 Sherline Products is proud to introduce its latest Vertical Milling machine. With the increase of popularity of Sherline mills in industrial, laboratory, and school training environments the need to produce larger parts has led to the development of an extended capacity milling machine. Sherline’s NexGen Mills are available in Manual, CNC-Ready, and full CNC configurations.

The new NexGen Mill has the following standard features:

- Extra-Rigid Column Base

- 15″ Extended Column Bed

- 18″ Extended Mill Table

- 18″ Mill Base

- 7″ x 13″ Tooling Plate (3 T-slots, Alignment Pins)

- Y-axis covers—Mill Accordion Way Cover Set and extended 12″ brass rear leadscrew cover

Other standard features include oilers on the X-, Y- and Z-axes to keep the column leadscrew and base saddle leadscrews and ways lubricated during extended CNC operations. In addition, backlash is adjustable on X-, Y- and Z-axes. Adjustable tapered plastic gibs provide a way to accommodate wear on the aluminum and steel dovetailed slides on all three axes.

NEW PRODUCT! (September 2015)

Lathe Headstock Hard Stop Kit P/N 40116

Starting in August, 2015 every Sherline headstock now includes the holes to add an optional hard stop. A hole through the headstock base allows the hard stop rod to be set to contact the lathe table, providing a hard stop for the Z axis during turning operations. For those who have an older Sherline lathe and want to add the hard stop, the kit includes instructions with dimensions on where your headstock case will need to be drilled to accept the rod and locking thumbscrew. Kit includes 4″ hard stop rod, 8″ hard stop rod and a 10-32 x 5/8” thumbscrew (lathe headstock purchased separately).

NEW PRODUCT! (June 17, 2015)

5C or ER collet to Sherline Chuck Arbors P/N 1065 and 1066

Install a Sherline 3-jaw or 4-jaw chuck in your full-size 1/2″ or 5/8″ lathe collet in seconds! These adapters have a straight shank that will slip into the collet and a 3/4-16 thread on the other end to hold any Sherline 2.5″ or 3.1″ chuck. Shanks are available to fit 1/2″ (P/N 10660) or 5/8″ collets (P/N 10650). When you are done with the job, just remove the chuck and arbor and go back to using your collets.