About the Pneumatic Bar Feeder Activation Cylinder Assembly

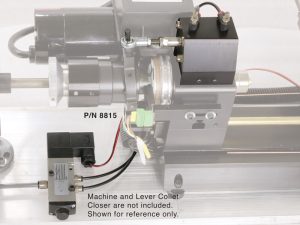

We separated the bar feeder (P/N 8840) into two sections (P/Ns 8815 & 8825) for our customers interested in building their own bar feeder system.

In addition to using this assembly for a bar feeder system, it can also be used as a programmable collet control to open and close the collet. Use M10 and M11 (chuck closed and chuck open, respectively) in your G-code program.

The Pneumatic Bar Feeder Activation Cylinder Assembly is the bar feeder section used in conjunction with our machine and our 3C lever collet closer to open and close the collet pneumatically. Click on the Instructions tab above to download the instructions for this assembly.

NOTE: This system is designed to work with the MASSO Touch control (with the G3 board). If you have an older MASSO G2 board, the G2 board is not compatible with the MASSO “relay module” that is needed. If you use a control system other than the MASSO Touch control, you will need to contact your control manufacturer for compatibility and wiring instructions. Most newer CNC controls are designed to incorporate signals to a relay to control external devices.