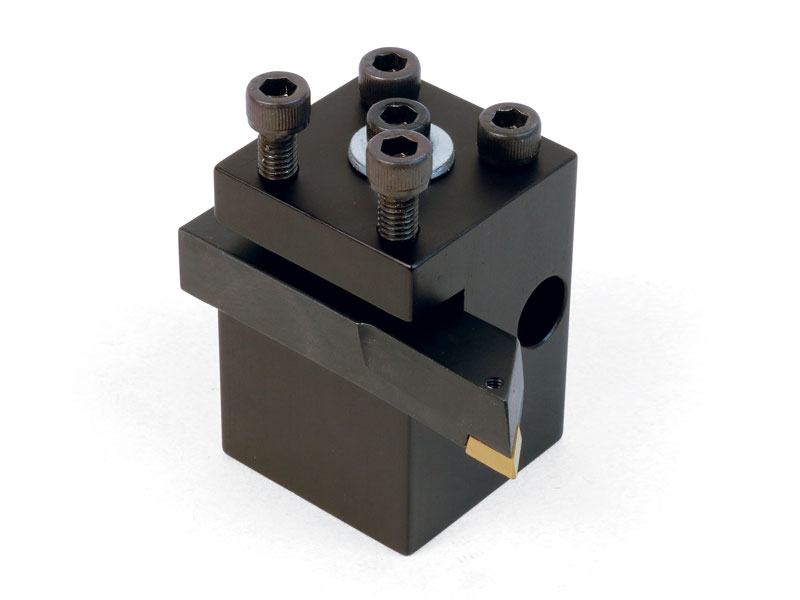

Product Description

This tool holder is designed to hold 3/8″ square tools on the “back” side of the part. The rear-mount tool holder is slightly taller than our standard #7600 Tool Post, allowing the tool to be mounted upside down and used on the backside of the crosslide. The round hole is for holding boring tools on center (tool not included) like Sherline’s own right- and left-hand 55° inserted tip tool holders.