Carbide Insert LH 80° 3/8″ Boring Bar w/2 Flats

Sherline’s gang-tooling tool post (P/N 5930) was specifically designed for customers converting their Sherline lathe into a chucker-style or gang-tooling lathe. Since most parts produced on a chucker lathe are 1/2″ (13 mm) in diameter or smaller, and the center-to-center spacing on our gang-tooling post is 1.5″ (38 mm), we identified a practical opportunity: our boring bars can double as both boring and outside diameter (O.D.) turning tools.

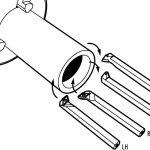

To support this dual use, we modified our standard boring bars by adding a second locating flat. This allows them to be mounted with the insert face up or face down, providing flexibility for front- or back-side operations. For example, right-hand 80° and 55° boring bars can now be used effectively on either side of the part (see Figure 1).

These 3/8″ diameter boring bars are designed to hold a 2-sided 80° carbide insert, secured with a Torx® screw. Each holder includes an 80° carbide insert and a Torx driver.

-

Each holder is 3-1/4″ long and can bore to a depth of just over 2″ when secured with two set screws.

-

Constructed from 1144 Stressproof® steel with a black oxide finish for strength and corrosion resistance.

See instructions below for additional guidance on using two-flat boring bars with gang tooling setups.

Pro Tip: Consider using the boring bar with the insert face down to help reduce chip buildup on the insert during cutting. This orientation can improve chip evacuation and extend insert life.

FIGURE 1—55° boring bars used as examples. The left-hand tools are used as turning tools, while the right-hand tools are used as boring tools.

Note: The straight-groove chip breaker shown in some older images is no longer available. Current inserts feature the spider web-style chip breaker as shown here

-

| Insert Holder Material | 1144 Stressproof Steel |

|---|---|

| Body Coating | Black Oxide |

| Insert Material | Carbide |

Related products

Threading/Grooving Carbide Insert Tool Holder

Due to the variety of insert types and their cost, the holder is sold separately without inserts, allowing you to select only the specific inserts you need. The holder includes a clamp, 6-32 hold-down screw, and a 7/64" hex key for secure setup.

⚠️ CUSTOMER NOTICE — July 8, 2020

We’ve identified a potential issue affecting a small number of our Threading/Grooving Carbide Insert Tool Holders. Specifically, the cutting insert may not be securely clamped in place.

When tightening the clamp, the inside corner of the clamp may contact the step adjacent to the insert pocket, preventing full engagement with the clamping notch on the insert. This was caused by an early in-house clamp design that mistakenly used symmetrical angles on both sides of the clamp nose, rather than the intended asymmetrical design. This issue has since been corrected.

[caption id="attachment_33596" align="alignright" width="300"] Click on the image for a larger view.[/caption]

Click on the image for a larger view.[/caption]

To resolve the issue immediately:

-

Use a bench grinder or file to slightly grind down the back side of the clamp (see blue circle in the image).

-

This will allow the clamp tip to clear the step (indicated by the red arrow), ensuring full contact and proper clamping of the insert.

⚠️ CAUTION: Chips coming off the carbide inserts can be very HOT! Use extreme caution. Carbide inserts can also shatter. For these reasons, proper protective eyewear and clothing are especially important when using these tools. Materials like tool steel can form long, stringy chips that wrap around the part. Use a chip brush frequently, or pause machining to clear debris. Accumulated chips, especially when hot, can ignite. Keep the area around the cutter clean and free of chip buildup.

RH 55° and 80° 3/8″ Boring Bars w/Carbide Inserts

These 3/8" diameter boring bars feature a carbide insert secured with a Torx® screw and come complete with a Torx wrench. Choose between:

-

A 55° right-hand insert, suitable for starting holes as small as 3/4", ideal for reaching sharp internal corners

-

An 80° insert, which fits into a smaller 1/2" hole and offers added strength for roughing operations

Each holder measures 3-1/4" long and can bore to a depth of just over 2" when properly secured with two set screws. Manufactured from durable 1144 Stressproof® steel with a black oxide finish, these tools are available individually or as a discounted set.

Why Choose Carbide Insert Tools?

While high-speed steel (HSS) remains common for small machine tools due to its low cost and resharpenability, carbide inserts offer significant advantages in demanding applications:

-

Longer-lasting edges when cutting hard metals like stainless steel, titanium, or abrasive materials such as carbon fiber

-

Faster cutting speeds and greater efficiency

-

Each insert can be rotated 180°, effectively giving you two cutting edges per insert

Although carbide inserts can't be resharpened, their durability and versatility make them a preferred choice in professional machine shops.

Note: The older straight-groove chip breaker insert is no longer available. Current inserts include the spider web-style chip breaker, as shown in the updated images here & here

Ceramic Insert Tool Holder

Designed for cutting hard materials like tool steel, this ceramic insert tool holder features a triangular insert mounted at a negative rake angle. The downward tilt of the insert provides proper side clearance, allowing you to use all six cutting edges—three per side—before needing a replacement. The 3/8" shank fits Sherline’s P/N 7600 tool post (not included). A clamp, hold-down screw, and 3/32" hex key are included for secure installation. Replacement inserts are available as (P/N 22659).

Why Use Ceramic Inserts?

Ceramic cutting tools are a powerful addition to the modern machinist’s toolbox. Though more brittle than high-speed steel (HSS) or carbide, ceramic inserts excel at cutting hardened steels and other tough materials, especially at higher spindle speeds. This makes them ideal for jobs that would otherwise be extremely difficult or impossible—such as turning down the shank of an end mill.

This insert’s large nose radius helps achieve an excellent surface finish, particularly when profiling.

-

Each insert offers six usable cutting edges:

-

Rotate 120° to access a new edge (3 per side), then

-

Flip the insert for 3 more cutting points on the opposite face

-

-

In comparison, traditional carbide inserts offer only 2–4 cutting edges, making ceramic inserts cost-effective over time, despite the higher upfront cost.

Usage Notes & Safety Information

-

Ceramic inserts are brittle and should be used with proper technique to avoid chipping or breakage.

-

Caution: Chips produced during cutting can be extremely hot—even red-hot. Use protective eyewear, gloves, and fire-safe clothing when operating.

-

Some materials, such as tool steel, may form long, stringy chips that wrap around the part ("bird’s nest" effect).

Use a chip brush and stop the machine frequently to clear chips. These chip clusters can ignite if they come in contact with hot chips.