Product Description

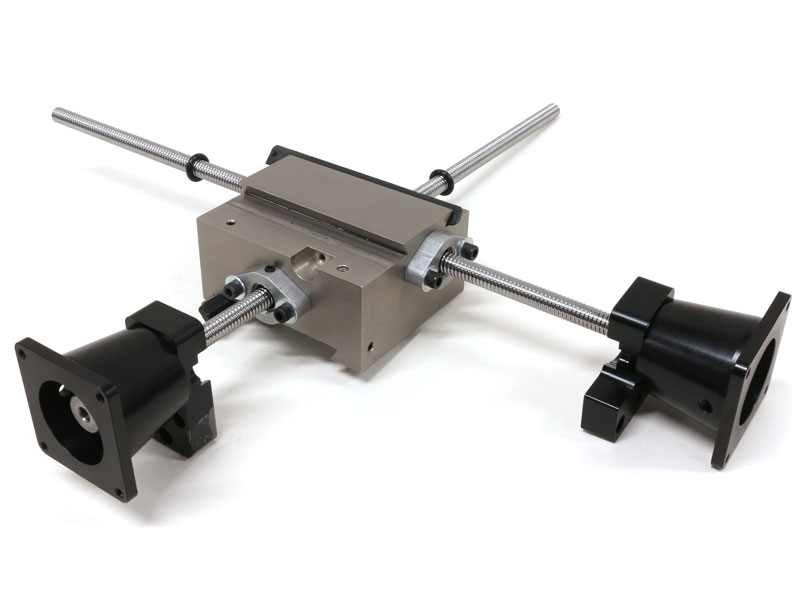

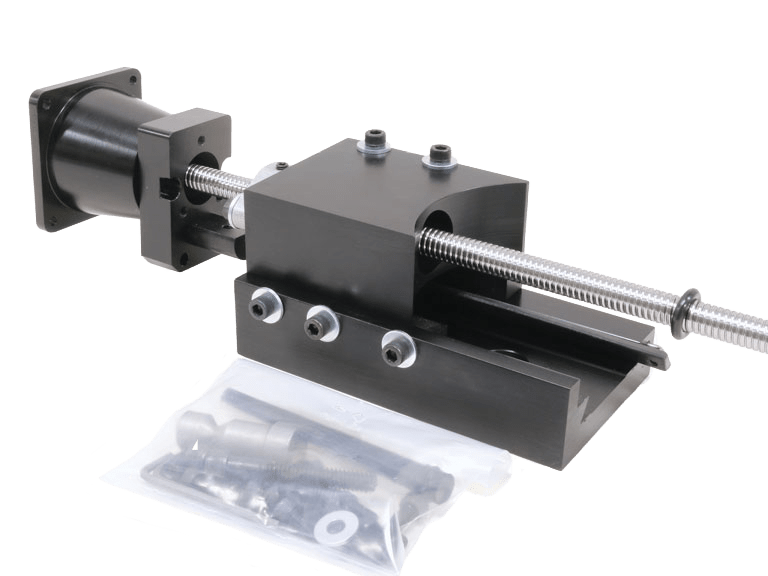

The key upgrade parts for this ball screw retrofit kit include ball leadscrews, stepper motor high-torque coupling, and the ball screw mill saddle (with nickel / Teflon plate).

Ball Leadscrew Specifications

- Rolled Ball Screw with BSH Nut

- 10mm Diameter, 2mm Lead

- C7 Accuracy*, P1 Preload

*C7 accuracy has a linear tolerance of 50 micrometers / 300mm or .002″ / 12.0″.

MILL COLUMN UPGRADE NOTICE: If you are upgrading your 12″ mill, you will need to order P/N 50054 Mill Column Base. The mill column base for the 12″ Ball screw machine has an additional 1/2″ through-hole to accommodate the larger ball screw and brass cover.

- The charge for all ball leadscrews is the same, regardless of the overall length. This is because the manufacturer does not give us a price break on the shorter screws (in fact, they wanted more for a 6″ ball screw). All screws come in at 400mm (15.75mm) long, and we cut them to length to fit the individual machine axis.

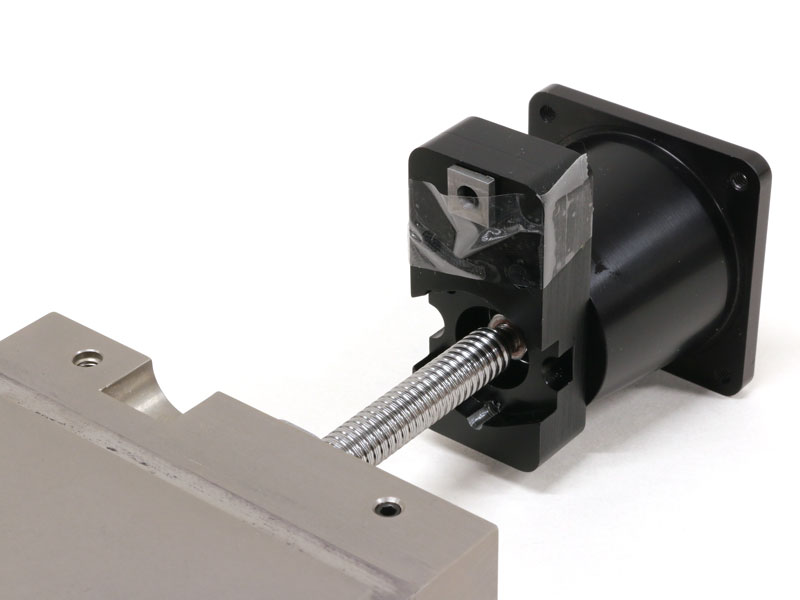

- All retrofits come with the stepper-motor mounts, high-torque couplings, bearings, preload nut, and ball screw fully assembled in our factory. We do not sell these parts individually for you to assemble.

- The ball leadscrew and the rest of the assembly are assembled and checked in our factory. We place an O-ring on the end of the ball screw, below the saddle, away from the motor mount. The O-ring is placed there to help ensure that the ball nut does not thread itself off the ball screw. If the ball nut threads off the ball screw, the balls in the ball nut will come out. At this point, the ball screw is scrap. There is no way to fix it! For this reason, the O-ring is to remain on the ball screw until the ball screw assembly is fully assembled on your machine. After you have assembled your ball screw on your machine, you may remove the O-ring.

NOTE: On retrofits, the only way possible for your ball leadscrew to have excessive slop (backlash), is if some of the balls have come out of the ball nut. We will not replace ball leadscrews that have excessive slop (backlash)!