Product Description

About the Sherline High-Torque Stepper Motors

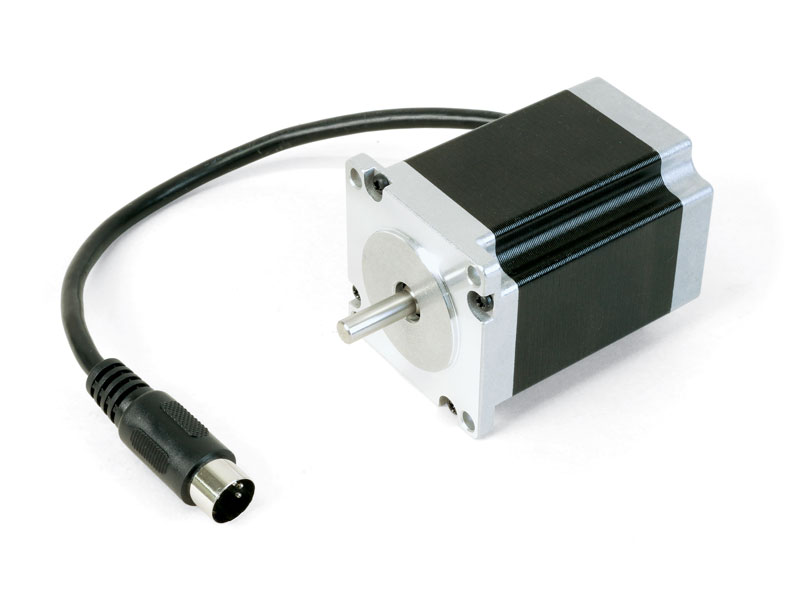

Our high-torque stepper motor has the same NEMA #23 frame as our standard stepper motor, but it has over 75% more torque. The maximum “Rapid Feed” will not change. Your cutting feed rate can be increased because you will be using a stepper motor that has higher torque. It is also better suited to handle the additional weight of the motor and headstock on our Z-axis.

ATTENTION: This new high-torque stepper motor required that we change the CNC coupling to handle the added load. If you are upgrading an older CNC machine that uses the old coupler (P/N 67105, discontinued) to use the high-torque stepper motors, please click on the link for P/N 671052 (sold separately).

Plug-and-Play Upgrade

The high-torque stepper motors can also be used on any Sherline CNC machine. The motor is two amps, just like our standard motors, so you can easily upgrade your current Sherline system with the new high-torque motors. (For example, Sherline Complete CNC systems or P/N 8760 CNC 4-axis driver box kit.)

NOTE: Referenced upgrades apply only to Sherline products.

Shafts and Flats

Sherline stepper motors have shafts at both ends, so a handwheel can be used for manual control if desired. Flats are ground onto each end of the shaft to accommodate set screws for handwheel and coupling. If a stepper motor is to be used with a Sherline motor mount, the shaft going into the coupling should have a flat machined or ground on it where the set screw bites into it. If this is not done, the point of the set screw can upset the shaft surface sufficiently, making it impossible to remove the coupling. For non-Sherline applications, the flat may not be necessary.

Powerful dual-shaft motors are prewired for quick hookup

Stepper motors have six wire leads pre-wired in a connector that plugs directly into the Sherline linear or rotary controller.

Stepper motors have six wire leads pre-wired in a connector that plugs directly into the Sherline linear or rotary controller.

Both the complete CNC system and the P/N 8760 driver box come with four cables pre-wired with a 5-pin plug. These match the plugs on the P/N 67127 stepper motors sold by Sherline. To hook up the system, you plug each stepper motor into the cable for the proper axis. It couldn’t get much easier than that.