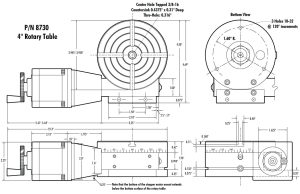

Product Description

The 4th Axis for your Sherline CNC Mill

Sherline’s CNC driver box comes equipped with an A-axis output cable ready to drive a 4th rotary axis. This rotary table is all you need to turn your Sherline CNC mill into a 4-axis machine. Just plug the A-axis cable from the external driver box or the built-in driver box in your Sherline computer into the matching plug on the stepper motor. The EMC2 software is already set up to handle G-code for the A-axis, and numbers entered after the letter “A” in your code are interpreted in degrees.

The same end result can be obtained by ordering a CNC ready rotary table and a stepper motor and attaching the motor, but this single part number does the same thing, making it easier to order and saving you the trouble of installing the motor on the rotary table.

NOTE: We are stating the following weight limits for our rotary tables for continual use. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

- Horizontal orientation—50 lbs.

- Vertical orientation—30 lbs.

- Vertical rotational torque—6 foot/lbs. (meaning it can lift a 6 lb. weight when suspended 12″ away from the center of the rotary table)

The rotary tables can hold more weight when they are not under a continual load.

Using the rotary table with the limit switches on the TAT

NOTE: For instructions on using the rotary table with the limit switches on the TAT, click on the Instructions tab above and download the PDF MASSO Rotary Table Limit Switch Interference on the Tilting Angle Table.