Product Description

Each of our four mill sizes is available as an XY base. You can purchase the base of any of our vertical mills as an XY base if you already own a vertical milling column for use with your lathe. The XY base offers a sturdier base and a larger work area than the lathe. Lathe owners can then swap the headstock and motor/speed control from their lathe to the vertical milling column in approximately 60 seconds.

XY bases have also found their way into the industrial market and are used in various manufacturing setups.

If You Have a Standard Mill Column Base

Please note that milling column bases made before 1995 must be modified in order to work with this XY base. You can return your older vertical milling column to the factory to be re-machined and used with an XY base rather than purchasing the entire vertical milling machine (Contact us for pricing).

Vertical milling column bases made after 1995 do not need to be modified. This combination saves you the amount of money included in the cost of the vertical mill for the column but gives you the same machine minus the headstock and motor/speed control.

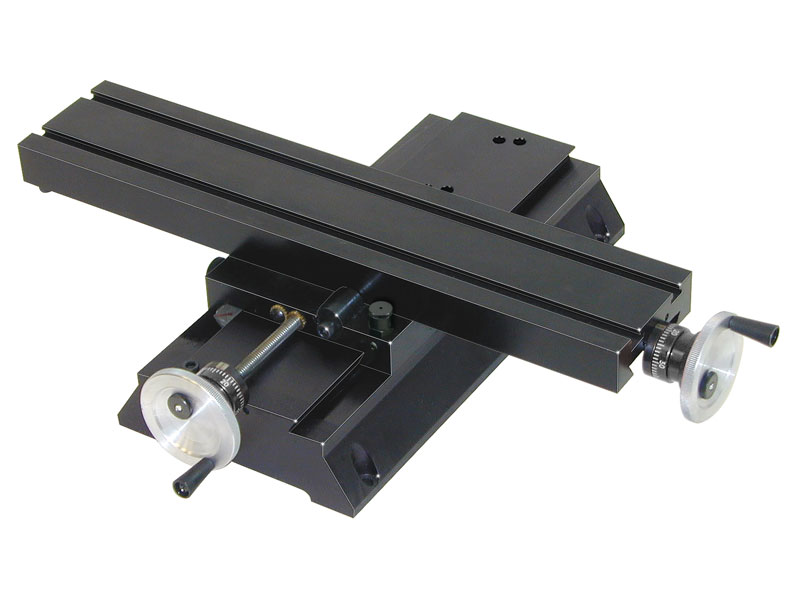

The Tabletop Mill XY base w/Zero Adjustable Handwheels is the same base used in our 5500-series tabletop mill.

Standard Features for the Tabletop Mill XY Base w/Zero Adjustable Handwheels

- 10″ Mill Base

- 13″ Mill Table

- 2″ (51mm) resettable, zero adjustable handwheels on the X- and Y-axes. Each handwheel has laser-engraved aluminum handwheel collars.

- Oil reservoir on the X/Y axes

- Travel: X=8.65″ (220 mm), Y=3.0″ (76 mm)

Optional Y-axis Leadscrew Cover Upgrades for the Mill XY Base

Brass tube cover for the rear of the Y-axis*

Accordion way cover for the front and rear of the Y-axis

Mill Column Base

*You must purchase the Mill Column Base (P/N 50050) to work with the brass tube cover.