|

The improper use of machine tools and their accessories can result in serious injury. Before using this tool, thoroughly read the instructions and make sure you understand its proper and safe use. |

Always wear safety glasses when operating machine tools. |

Single-Axis Slide with Programmable CNC Contoller

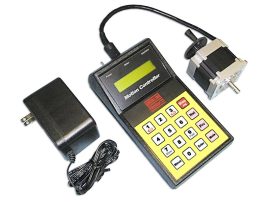

Sherline’s single-axis controllers are designed to drive the stepper motor on any individual axis of a lathe or mill—no separate computer or driver is required. Each controller features an integrated computer chip within the keypad/control unit, allowing you to operate the motor directly from the keypad or enter simple programmed sequences—no G-code knowledge needed.

You can program parameters such as direction, travel distance, feed rate, and whether to pause between operations or proceed automatically to the next step. The controller can store up to 40 steps (each with four parameters) in either of two user-defined programs. Multiple controllers can be linked via cable to synchronize movements or can be connected to a larger CNC system using “sense” and “acknowledge” signals to coordinate actions within a CNC sequence.

Stepper Motor Mounting & Drive System

Each stepper motor mount includes dual ball bearings with a preload nut to eliminate endplay. A dampened coupling connects the motor’s 1/4″ diameter shaft to the leadscrew. The dual-shaft stepper motor also allows for manual operation using the provided handwheel. The controller employs micro-stepping for precise, smooth movement.

Mounting Options

-

From the Bottom: Four 1/4-20 holes on 2″ centers in the base for mounting from below.

-

From the Top: If bottom access is unavailable, use the included four angle clamps that fit into the perimeter groove of the base. Drill and tap the mounting surface for the included 10-32 socket head cap screws. Use all four clamps for maximum stability.

Included Components (Linear Machine Slide with Programmable Controller)

-

Single-axis slide with your choice of 8″, 13″, or 18″ table

-

Linear controller with integrated keypad

-

Power supply

-

NEMA #23 frame size stepper motor

-

1-5/8″ handwheel, graduated in .001″ increments (inch) or .01 mm increments (metric)

-

Cables

-

Complete instructions

Power Supply

The included power supply operates on 115/120 VAC, 60 Hz (38 W). For regions with 100, 220, or 240 VAC and/or 50 Hz power, a step-down transformer is required. Alternatively, you may supply 24VDC, 1A (1000 mA) from a compatible local power source. Sherline does not offer a 220V power supply or transformer.

Weight Capacity

The slide has a weight capacity of approximately 10 lbs, depending on table length and load placement. For an 18″ table, limit off-center loads (at the table end) to no more than 10 lbs. Heavier loads may be supported if centered near the base.

Duty Cycle & Maintenance

Under heavy, continuous use, you may observe wear on the anodized dovetail surfaces after one year (approx. 2080 hours). The slide remains fully functional, but regular lubrication with light oil is recommended to maximize lifespan.

IMPORTANT: Do not use WD-40 for lubrication. It will strip the anodized coating.

-

Linear Controller Specs

| Power Supply | Input: 115 VAC 50/60 Hz, Output: 24V, 1 Watt |

|---|---|

| Stepper Motor | 100 oz-in, 2 Amp, #23 Frame size, 400 steps per revolution |

| Speed | 1″/min. to 25 in/min (programmable) |

| Distance | from 0.0005″ to 9.9995″ in steps of 0.0005″ |

| Backlash Compensation | Programmable |

Table Specs

| 6550 (6551) 8″ table | 6555 (6556) 13″ table | 6550-18 (6551-18) 18″ table | |

|---|---|---|---|

| Table size | 2.75″ x 8″ (70 mm x 203 mm) | 2.75″ x 13″ (70 mm x 330 mm) | 2.75″ x 18″ (70 mm x 458 mm) |

| Table height | 2″ (51 mm) | 2″ (51 mm) | 2″ (51 mm) |

| Table travel | 4″ (102 mm) | 8″ (203 mm) | 14″ (356 mm) |

| Hold-down provision | 2 T-slots | 2 T-slots | 2 T-slots |

| Mounting provision | 4 holes 1/4-20 in the bottom of the base plus slot for angle clamps | 4 holes 1/4-20 in the bottom of the base plus slot for angle clamps | 4 holes 1/4-20 in the bottom of the base plus slot for angle clamps |

| Handwheel | 1-5/8″ laser engraved aluminum with two pre-loaded ball bearings | 1-5/8″ laser engraved aluminum with two pre-loaded ball bearings | 1-5/8″ laser engraved aluminum with two pre-loaded ball bearings |

Industrial Slide Tables

| Part No. | Description | Quantity |

|---|---|---|

| 12050 | 8-32 x 3/8″ Socket Head Cap Screw | 4 |

| 30561 | 10-32 T-Nut | 4 |

| 35580 | Angle Clamp | 4 |

| 40080 (41040 Metric) | 1-5/8″ Handwheel | 1 |

| 40520 | 10-32 x 3/16″ Cup Point Set Screw | 3 |

| 40690 | 10-32 x 3/4″ Socket Head Cap Screw | 4 |

| 40740 | 10-32 x 7/8″ Socket Head Cap Screw | 1 |

| 40820 | Gib Lock | 1 |

| 40890 (41890 Metric) | Leadscrew Nut | 1 |

| 40980 | Gib | 1 |

| 44210 (44220 Metric) | 8″ Leadscrew (6554/6554M) | 1 |

| 50171 (51171 Metric) | 13″ Leadscrew (6559/6559M) | 1 |

| 50173 (51773 Metric) | 18″ Leadscrew (6554-18/6554M-18) | 1 |

| 50150 | Backlash Lock Star Gear | 1 |

| 50210 | Button Head Socket Screw | 1 |

| 50130 (51130 Metric) | Backlash Lock Nut | 1 |

| 65501 | Base | 1 |

| 65502 | Table Lock | 1 |

| 67036 | 8″ Slide Table (6554/6554M) | 1 |

| 67050 | 13″ Slide Table (6559/6559M) | 1 |

| 54182 | 18″ Slide Table (6554-18/6554M-18) | 1 |

| 67101 | CNC Mount | 1 |

| 671052 | CNC Coupler | 1 |

| 67106 (67108 Metric) | Preload Nut | 1 |

| 67111 | 8-32 x 7/8″ Socket Head Cap Screw | 2 |

| 67115 | 5-40 x 1” Socket Head Cap Screw | 1 |

| 67120 | Ball Bearing W/ Flange | 2 |

CNC Linear Controller

| Part No. | Description | Quantity |

|---|---|---|

| 67127 | Stepper motor assembly | 1 |

| 87041 | 120 VAC power supply (24 VDC, 1 amp output) | 1 |

| 87250 | Stepper motor-to-control box 6’ extension cable | 1 |

| 87350 | Single 5-pin mini-DIN limit switch cable or ½ of daisy-chain cable | 1 |

| 88010 | Linear controller/keypad unit complete | 1 |

Click the P/Ns below to download a zipped version of the IGS 3D CAD file. You will need to extract the zip file before viewing the IGS file.

8″ 6554/6554M 3D IGS model

13″ 6559/6559M 3D IGS model

18″ 6554-18/6554M-18 3D IGS model

You need an IGS viewer to view .igs files. CLICK HERE to download a FREE IGS viewer.

Related products

Stepper Motor Spindle Mount Kit

CNC Linear Controller with Stepper Motor

This stand-alone controller is fully programmable via its integrated keypad and directly controls the stepper motor to which it is connected. The stepper motor can be applied to any axis of a CNC-Ready Sherline machine.

An 8-pin mini-DIN cable allows multiple controllers to be connected in a “daisy-chain” configuration. Controllers can signal one another to operate in sequence, enabling complex, multi-axis movements without the need for a computer or master CNC controller. The system can also be used alongside existing CNC controllers. Each controller stores two independent programs, with up to 40 operations per program. For each operation, you can define travel distance, direction, feed rate, and whether the sequence pauses or proceeds to the next step.

The linear controller can also be daisy-chained with Sherline’s rotary controller, enabling coordinated rotary and linear motion. This allows users to easily perform advanced operations—such as gear cutting—without requiring CNC programming skills beyond simple keypad inputs.

Included with the CNC Linear Controller:

-

Linear controller with keypad

-

Power supply

-

#23 frame size stepper motor

-

Cables

-

Complete instructions

Note: To add CNC linear control to an axis on a Sherline machine that does not have a stepper motor mount, see P/N 8850.

Power Supply Compatibility:

The included power supply operates on 110–240 VAC and automatically adjusts for global use (220–240V). Earlier versions of this product shipped with a 110 VAC-only power supply.

CNC Rotary Table Indexer

Sherline has advanced its precision 4" rotary table into the 21st century with the addition of Computer Numerical Control (CNC). This upgrade makes it an ideal solution for clockmakers, gear cutters, and anyone needing to machine intricate radially symmetrical patterns. The CNC rotary table takes the complexity out of repetitive indexing tasks.

Complete, Stand-Alone System

Programming is done entirely through the integrated numeric keypad—no computer required. The system includes everything needed for operation:

-

4" Sherline rotary table with pre-installed stepper motor

-

Microprocessor unit with numeric keypad

-

115 VAC power supply (universal 110–240 VAC compatible)

-

All required connecting cables

Mounting Options

The rotary table includes clamps and T-nuts for mounting to the T-slots of a Sherline mill table. Additional options allow for flexible positioning:

-

Right-Angle Attachment: Holds the table vertically at a 2.7" center height. A matching right-angle tailstock is also available for supporting long workpieces.

-

Tilting Angle Table: Allows mounting at any angle from 0° to 90°. At 90°, the center height remains 2.7", compatible with the right-angle tailstock.

Simple, Accurate Operation

Simply enter the steps per revolution (or degrees per step) via the keypad. The table advances precisely to the next position at the press of a button. If needed, previous positions can be recalled instantly.

-

Resolution: 28,800 steps per revolution

-

Accuracy: ±0.006° per step

This precision allows for accurate machining of gears with odd numbers of teeth, and built-in calculations prevent cumulative errors.

Flexible Integration

This CNC rotary indexer is a complete, stand-alone unit—perfect for complex indexing operations. It can also integrate with other CNC systems:

-

Accepts input signals from an external CNC controller

-

Sends “completion” signals back to the master controller

-

Can be daisy-chained with other units for coordinated actions

For more advanced applications, the rotary table can be linked with Sherline’s linear controller (P/N 8800), enabling seamless combinations of rotary and linear motion—ideal for gear cutting and other multi-axis operations, all without requiring advanced CNC programming knowledge.

Weight Capacity (Continuous Use)

-

Horizontal orientation: 50 lbs

-

Vertical orientation: 30 lbs

-

Vertical rotational torque: 6 ft-lbs (e.g., able to lift a 6 lb. weight 12" from the center)

Note: The table can handle heavier loads if not under continuous use. Refer to the Video tab for practical examples.

Power Supply

The controller power supply operates on 110–240 VAC and automatically adjusts for global use. (Earlier models included a 110 VAC-only power supply.)

Compatibility with Tilting Angle Table (TAT) Limit Switches

For instructions on using the rotary table with limit switches on the TAT, see the “Instructions” tab and download the PDF titled MASSO Rotary Table Limit Switch Interference on the Tilting Angle Table.

High-Torque Stepper Motor

Sherline’s high-torque stepper motor features the same NEMA 23 frame size as our standard stepper motor but delivers over 75% more torque - ideal for increased cutting feed rates and better performance on the Z-axis, where it can handle the added weight of the motor and headstock. Note that maximum rapid feed rate remains unchanged.

Important Compatibility Note: Due to the increased torque, these motors require an updated CNC coupler (P/N 671052, sold separately). If upgrading from systems using the discontinued coupler (P/N 67105), ensure you purchase the correct replacement.

Rated at 2 amps, these motors are fully compatible with all Sherline CNC machines, including complete CNC systems, our 4-axis driver box, CNC rotary tables and our linear and rotary motion controllers. No additional power supply upgrades are needed.

Dual-shaft design allows handwheel operation for manual control. Flats are precision-ground on both ends to secure handwheels and couplers via set screws. When used with Sherline motor mounts, the shaft end engaging the coupler must have a flat to prevent damage from the set screw. This may not be necessary in non-Sherline applications.

Each motor includes a six-lead cable with a 5-pin connector, pre-wired to interface seamlessly with Sherline's CNC equipment, making setup fast and easy - just plug in and go.