Product Description

About the Sherline CNC-Ready 4″ Reverse Rotary Table

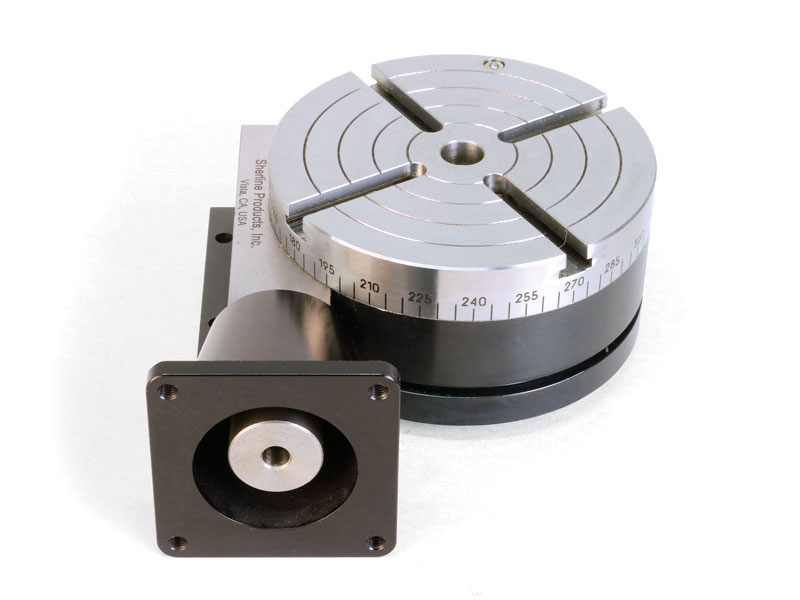

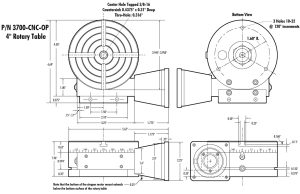

Sherline has taken its manual 4″ rotary table with reverse mount and applied a stepper motor mount with dampened coupling in place of the handwheel. The mount accepts a NEMA #23 frame size stepper motor for CNC control. This allows the table to be used as a 4th axis with CNC systems that have the capability to drive a rotary axis.

The reverse rotary table is perfect for using on the tilting angle table. The reverse mount allows access to the handwheel from the front of the machine (see photo below). If you used a standard rotary table in the previously described set-up the handwheel would be mounted facing the backside of the X-axis.

NOTE: When the worm housing is reversed to the opposite side, a clockwise rotation of the handwheel or stepper motor will result in a counter-clockwise rotation of the rotary table.

Weight Limitations for Continuous Use

We are stating the following weight limits for our rotary tables for continual use.

- Horizontal orientation—50 lbs.

- Vertical orientation—30 lbs.

- Vertical rotational torque—6 foot/lbs. (meaning it can lift a 6 lb. weight when suspended 12″ away from the center of the rotary table)

The rotary tables can hold more weight when they are not under a continuous load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

NOTE: CNC-ready machines cannot be operated manually unless double-shaft stepper motors are installed.

- 1 Hold Down Set

- 1 37090 Chuck Adapter

If you would like to convert your current rotary table to the reverse set-up you can send it back to Sherline and we can make the change for a $104.25 charge (includes parts and labor). Just fill out the RMA Request form to received instructions on how to send items back to us.

NOTE: Because components of the table are ground as a set during production, the P/N 3700-OP rotary table cannot be upgraded to the P/N 3700-CNC-OP version later on. A new rotary table with stepper motor worm housing must be purchased.

For in-depth details about the Sherline CNC-Ready 4″ Rotary Table CLICK HERE.

Using the rotary table with the limit switches on the TAT

NOTE: For instructions on using the rotary table with the limit switches on the TAT, click on the Instructions tab above and download the PDF MASSO Rotary Table Limit Switch Interference on the Tilting Angle Table.