Larger parts that can ship USPS to Canada/International

Sherline/Acorn CNC Controller

[icon icon=icon-chevron-down size=14px color=#000 ] Controller Features

Custom control housing includes:- Centroid Acorn CNC control board

- Acorn plug-and-play relay module (mounted and pre-wired)

- Internal wiring to DB9, DB25, and 2-wire Molex connectors

- Power supply, push-to-reset circuit breaker, and cooling fan

- External Ethernet port, power switch, and power LED

- Ethernet connection

- Power switch and power LED

- Cooling fan

- Three DB25 connectors:

- Sherline 4-axis driver box

- Aux 4-axis control for additional drives/axes

- Relay card

- Three DB9 connectors:

- Limit switches

- External encoder*

- Aux tool setter or touch probe (one at a time)

- Three 2-wire Molex connectors:

- E-stop button

- Spindle control

- Laser

- Dual logic power: 5 VDC and 24 VDC

- Input power: 100–120 VAC or 208–240 VAC, 50/60 Hz

- 15 ft shielded Ethernet cable (controller to PC)

- External E-stop with 2 ft cord

[icon icon=icon-chevron-down size=14px color=#000 ] Compatibility & Connection Options

- The controller connects directly to Sherline 24 V stepper motors via the Sherline 4-axis driver box (P/N 8760).

- Not compatible with MASSO 36 V closed-loop stepper motors.

- For DIY users with their own motors/drives, use the “Aux 4-axis” DB25 connector. Wiring information for DIY customers is available under the Specifications/Downloads.

[icon icon=icon-chevron-down size=14px color=#000 ] Software & Conversational CAM

A free version of Centroid CNC12 is included with each Acorn kit for initial setup. However, it is strongly recommended that you purchase the Centroid Acorn “Pro” CNC12 Software License to unlock full conversational CAM (Intercon). Use the options below or visit: CLICK HERE for Acorn “Pro” CNC12 Software License details Intercon Conversational CAM:- Program directly from hand sketches or prints

- Import DXF files and generate G-code without separate CAD/CAM

- Ideal for new CNC users and those unfamiliar with traditional G-code programming

[icon icon=icon-chevron-down size=14px color=#000 ] Typical Use Cases

DIY Customer- Buys CNC-ready Sherline machines and installs their own motors, drives, and encoders.

- Purchase the base Sherline/Acorn CNC Controller (P/N 9400) without options and wire to your own hardware.

- Upgrading an existing Sherline CNC system including older OEM systems such as Denford, D&M, LabVolt, Paxton-Patterson, or Light Machines. For a sample Denford/Sherline Microlathe conversion using Acorn, see: Centroid Denford/Sherline Microlathe Conversion

- If you already have a Sherline Linux PC or 4-axis driver box, configure the controller

with:

- Spindle Control Isolator Board

- External Encoder kit for your headstock (Standard or 3C)

- Wants a complete Sherline system: CNC-ready machine, 24 V stepper motors, 4-axis driver box, spindle control isolator board, and external encoder.

- The Sherline/Acorn Controller is designed to support all of these configurations.

[icon icon=icon-chevron-down size=14px color=#000 ] Important Notes for Spindle Control

- To control spindle speed via G-code, you must have a motor drive or the Spindle Control Isolator Board and an external encoder installed.

- These components work together to accurately acquire and control spindle RPM.

- If you do not include the Spindle Control Isolator Board at the time of purchase, adding it later will require returning the controller to Sherline for installation. Email orders@sherline.com for return instructions.

Sherline Standard Morse #1 Taper Spindle Headstocks

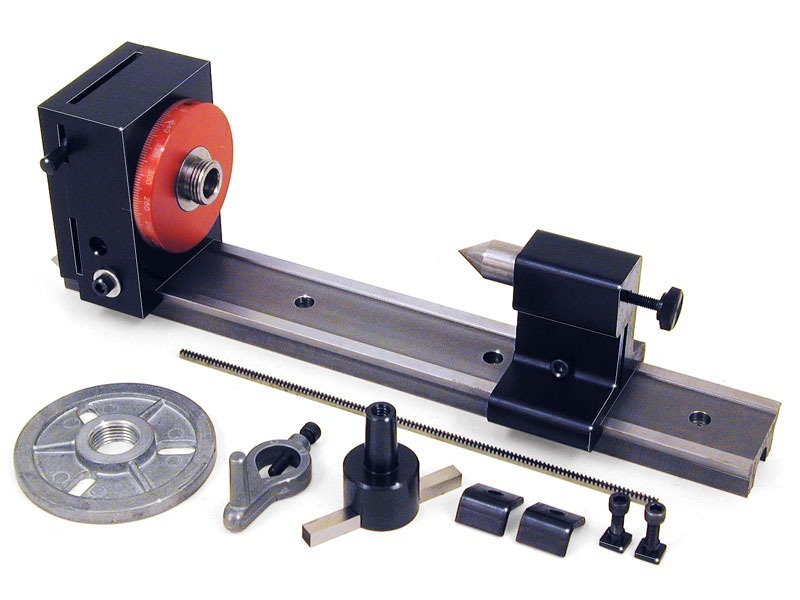

CNC-Ready Lathe Upgrade Kits

LATHE KITS

CNC-Ready Mill Upgrade Kits

DC motor

Electric Motor Specifications from Manufacturer Type of enclosure: Totally enclosed, non-vented Duty rating: Continuous–10 oz. in. at 6100 rpm, .85 amperes; Intermittent–30 oz. in. at 5500 rpm, 1.75 amperes (5 minutes on / 15 minutes off) Output horsepower: .06 KW (60 W) at … Continued

13″ Lathe Crosslide Assembly – DRO

13″ Lathe Crosslide Assembly – Manual

This 13" crosslide is designed for users who want to convert their Sherline lathe into a Chucker Lathe or gang-tooling lathe. Its extended length allows for mounting multiple gang-tooling tool posts along the crosslide.

The 13" crosslide measures .870" thick, compared to .625" for the standard 6" crosslide. Due to its increased thickness, this crosslide is not recommended as a direct replacement for standard lathe use. To bring the tooling on center with the headstock, a Headstock Riser Plate is required.

When using this setup, note that:

-

The tailstock cannot be used, as we offer a riser for the headstock only - not for the tailstock.

-

Turning between centers will no longer be possible.

-

Certain accessories, such as the thread-cutting attachment, are not compatible with the thicker crosslide.

The 13" crosslide includes a leadscrew and a standard 1-5/8" handwheel, saddle not included.

18″ Extended Mill Table

By popular demand, particularly in the CNC market, Sherline now offers an extended mill table that is 18″ long, extending the X-axis travel to 12.38″. It is the same width and thickness as the standard 13″ table and the T-slots … Continued

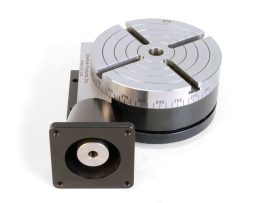

Manual Rotary Table

Nickel-Teflon Coated Manual Rotary Table

CNC-Ready Rotary Table

Nickel-Teflon Coated CNC-Ready Rotary Table

CNC Rotary Table with Stepper Motor

Nickel-Teflon Coated CNC Rotary Table with Stepper Motor

CNC Rotary Table with 36V Stepper Motor

Rotary Table Indexer

Sherline has advanced its precision 4" rotary table into the 21st century with the addition of Computer Numerical Control (CNC). This upgrade makes it an ideal solution for clockmakers, gear cutters, and anyone needing to machine intricate radially symmetrical patterns. The CNC rotary table takes the complexity out of repetitive indexing tasks.

Complete, Stand-Alone System

Programming is done entirely through the integrated numeric keypad—no computer required. The system includes everything needed for operation:

-

4" Sherline rotary table with pre-installed stepper motor

-

Microprocessor unit with numeric keypad

-

115 VAC power supply (universal 110–240 VAC compatible)

-

All required connecting cables

Mounting Options

The rotary table includes clamps and T-nuts for mounting to the T-slots of a Sherline mill table. Additional options allow for flexible positioning:

-

Right-Angle Attachment: Holds the table vertically at a 2.7" center height. A matching right-angle tailstock is also available for supporting long workpieces.

-

Tilting Angle Table: Allows mounting at any angle from 0° to 90°. At 90°, the center height remains 2.7", compatible with the right-angle tailstock.

Simple, Accurate Operation

Simply enter the steps per revolution (or degrees per step) via the keypad. The table advances precisely to the next position at the press of a button. If needed, previous positions can be recalled instantly.

-

Resolution: 28,800 steps per revolution

-

Accuracy: ±0.006° per step

This precision allows for accurate machining of gears with odd numbers of teeth, and built-in calculations prevent cumulative errors.

Flexible Integration

This CNC rotary indexer is a complete, stand-alone unit—perfect for complex indexing operations. It can also integrate with other CNC systems:

-

Accepts input signals from an external CNC controller

-

Sends “completion” signals back to the master controller

-

Can be daisy-chained with other units for coordinated actions

For more advanced applications, the rotary table can be linked with Sherline’s linear controller (P/N 8800), enabling seamless combinations of rotary and linear motion—ideal for gear cutting and other multi-axis operations, all without requiring advanced CNC programming knowledge.

Weight Capacity (Continuous Use)

-

Horizontal orientation: 50 lbs

-

Vertical orientation: 30 lbs

-

Vertical rotational torque: 6 ft-lbs (e.g., able to lift a 6 lb. weight 12" from the center)

Note: The table can handle heavier loads if not under continuous use. Refer to the Video tab for practical examples.

Power Supply

The controller power supply operates on 110–240 VAC and automatically adjusts for global use. (Earlier models included a 110 VAC-only power supply.)

Compatibility with Tilting Angle Table (TAT) Limit Switches

For instructions on using the rotary table with limit switches on the TAT, see the “Instructions” tab and download the PDF titled MASSO Rotary Table Limit Switch Interference on the Tilting Angle Table.

Nickel-Teflon Coated CNC-Rotary Table Indexer

CNC Rotary Controller with Stepper Motor

67127 2 Amp, 100-oz., 23 frame size stepper motor 87041 120 VAC power supply (24 VDC, 1 amp output) 87100 Control unit with keypad/electronics 87250 Motor-to-keypad 6’ extension cable 87350 Remote (limit) switch/daisy-chain 1/2 cable About the Controller Power Supply … Continued

3D Scanning Plates for CNC Rotary Table

Hole dimensions and locations on our scanner plates Click on the images below for a larger view.

CE Compliant Noise Suppression Filter