-

Inch: 1/4-20 leadscrew, 50 divisions

-

Metric: 6.3 x 1 mm leadscrew, 100 divisions

-

Maintains a constant feed rate for smoother, more consistent surface finishes

-

Minimizes errors from miscounting handwheel revolutions

-

Eliminates physical effort during long cuts or when returning the saddle to the starting position

-

Linear controller with keypad

-

Power supply

-

#23 frame size stepper motor

-

Cables

-

Stepper motor mount

-

15" leadscrew

-

Dampened coupling

-

Preload nuts

-

Drill guide block

-

Complete installation and operating instructions

-

Provides a constant feed rate for a smoother, more consistent surface finish

-

Reduces the chance of errors caused by miscounting handwheel revolutions

-

Eliminates physical effort for long cuts or returning the saddle to the starting position

-

Linear controller with integrated keypad

-

Power supply

-

#23 frame size stepper motor

-

Cables

-

Stepper motor mount

-

24" leadscrew

-

Dampened coupling

-

Preload nuts

-

Drill guide block

-

Complete installation and operating instructions

-

Linear controller with integrated keypad

-

Power supply

-

#23 frame size stepper motor

-

Cables

-

Stepper motor mount

-

Dampened coupling

-

Preload nuts

-

Drill guide block

-

Complete installation and operation instructions

- A constant feed rate gives a smoother, more consistent final finish

- The chance of errors due to miscounting handwheel revolutions is reduced

- No physical effort is needed for long cuts or returning the saddle to its starting position after a cut is complete

- Linear Controller w/Keypad

- Power Supply

- #23 Frame Size Stepper Motor

- Cables

- Stepper motor mount

- Z-axis Leadscrew

- Dampened coupling

- Preload nuts

- Drill guide block and complete installation and use instructions

-

Linear controller with keypad

-

Power supply

-

#23 frame size stepper motor

-

Cables

-

Complete instructions

- NEMA 23 frame size – fits Sherline CNC-ready mills, lathes, and rotary tables.

- Dual-shaft design – both ends of the shaft are usable; flats are ground on each end for secure attachment of handwheels and couplings.

- Standard step angle – 1.8° per step (200 steps/rev) for precise motion control.

- 2.0 A/phase – both motors are rated at 2.0 amps and work with existing Sherline CNC power supplies and driver electronics.

- 6-lead wiring – allows use in a variety of bipolar or unipolar configurations (see spec sheets for wiring diagrams).

- Designed for Sherline CNC – plug-and-play with Sherline driver boxes and motion controllers when used with the supplied connectors.

- Coupler requirement: Because of the increased torque, the high-torque motor (P/N 67126) must be used with the updated CNC coupling (P/N 671052). This coupling replaces the older 3-slot coupling (P/N 67105).

- Motor mounts: When used with a Sherline stepper motor mount (P/N 67101), be sure that the shaft entering the coupling has a flat aligned with the set screw. Tightening against the round shaft can damage the shaft and make removal difficult.

- Handwheel use: The dual-shaft design lets you mount a handwheel on the rear shaft for manual operation when the drivers are powered down. When the motors are energized, they hold position and cannot be moved easily by hand.

- Controller compatibility: P/N 67127 with the 5-pin DIN plug is designed to plug directly into Sherline’s 4-axis driver box, CNC systems, and linear and rotary controllers. P/N 67130 (no plug) is intended for non-Sherline or custom controllers.

- CNC-ready with factory-installed stepper motor mounts (X and Z axes)

- Turns parts up to 3.5″ (90 mm) diameter over the bed

- 15″ (381 mm) bed provides extended travel for longer workpieces

- 6″ (152 mm) crosslide for increased tool reach

- Precision-machined dovetail slides with adjustable gibs and backlash

- High-accuracy spindle and headstock used across all Sherline lathes

- Manual control possible with included handwheels

- Compatible with Sherline’s full line of accessories

- Made in the USA

- Model making and miniatures

- Prototyping and custom part production

- Educational CNC training programs

- Hobbyist and light industrial use

- CNC-ready with factory-installed stepper motor mounts (X and Z axes)

- Turns parts up to 3.5″ (90 mm) diameter over the bed

- 17″ (430 mm) bed provides extended travel for longer workpieces

- 8″ (200 mm) crosslide for increased tool reach

- Precision-machined dovetail slides with adjustable gibs and backlash

- High-accuracy spindle and headstock used across all Sherline lathes

- Manual control possible with included handwheels

- Compatible with Sherline’s full line of accessories

- Made in the USA

- Model making and miniatures

- Prototyping and custom part production

- Educational CNC training programs

- Hobbyist and light industrial use

- A powerful 90V DC motor with electronic speed controller

- 10″ base

- Brass leadscrew cover that keeps chips off the rear of the Y-axis leadscrew

- 2.75″ (70 mm) x 13.0″ (330 mm) table with laser-engraved scales and two T-slots

- Standard handwheels that can be mounted to the end of the stepper motors to maintain manual control when needed:

- (2) 2″ (51 mm) handwheels on X- and Y-axes

- (1) 2-1/2″ (63 mm) handwheel on Z-axis

- All with laser-engraved aluminum collars

- NOTE: CNC-ready machines cannot be operated manually unless double-shaft stepper motors are installed.

- Pulleys, drive belt, three hexagonal keys, spindle bars, gib removal tool, eight-foot three-wire power cord, and instruction manual

- Oil reservoirs on the X/Y axes and the Z axis help keep critical parts lubricated. These were initially developed for CNC machines that run constantly for hours on end but can benefit manual machines as well

- A powerful 90V DC motor with electronic speed controller

- 12″ base with laser-engraved scales

- Brass leadscrew cover that keeps chips off the rear of the Y-axis leadscrew

- 2.75″ (70 mm) x 13.0″ (330 mm) table with laser-engraved scales and two T-slots

- 1.235″ headstock spacer block

- Resettable, zero-adjustable handwheels that can be mounted to the end of the stepper motors to maintain manual control when needed:

- (2) 2″ (51 mm) handwheels on X- and Y-axes

- (1) 2-1/2″ (63 mm) handwheel on Z-axis

- All with laser-engraved aluminum collars

- NOTE: CNC-ready machines cannot be operated manually unless double-shaft stepper motors are installed.

- ¼” Drill Chuck w/ key, #1 Morse arbor with drawbolt

- Pulleys, drive belt, three hexagonal keys, spindle bars, gib removal tool, eight-foot three-wire power cord, and instruction manual

- Oil reservoirs on the X/Y axes and the Z axis help keep critical parts lubricated. These were initially developed for CNC machines that run constantly for hours on end but can benefit manual machines as well

- The headstock pivots up to 90° left or right.

- The column bed also rotates side to side up to 90°, enabling angled drilling.

- A specialized knuckle joint allows the column to tilt front to back.

- The ram-style column base can swing side to side up to 90°, offering even greater flexibility.

- Loosening the column cap lets the ram move in and out, providing over 5.5″ of additional travel.

- A powerful 90V DC motor with electronic speed controller

- 14″ base with laser-engraved scales

- Brass leadscrew cover that keeps chips off the rear of the Y-axis leadscrew

- 2.75″ (70 mm) x 13.0″ (330 mm) table with laser-engraved scales and two T-slots

- 2" column riser block

- Resettable, zero-adjustable handwheels that can be mounted to the end of the stepper motors to maintain manual control when needed:

- (2) 2″ (51 mm) handwheels on X- and Y-axes

- (1) 2-1/2″ (63 mm) handwheel on Z-axis

- All with laser-engraved aluminum collars

- NOTE: CNC-ready machines cannot be operated manually unless double-shaft stepper motors are installed.

- ¼” Drill Chuck w/ key, #1 Morse arbor with drawbolt

- Pulleys, drive belt, three hexagonal keys, spindle bars, gib removal tool, eight-foot three-wire power cord, and instruction manual

- Oil reservoirs on the X/Y axes and the Z axis help keep critical parts lubricated. These were initially developed for CNC machines that run constantly for hours on end but can benefit manual machines as well

- A powerful 90V DC motor with electronic speed controller

- 18″ mill base with Y-axis leadscrew protection

- 2.75″ (70 mm) × 18.0″ (457 mm) extended mill table with two T-slots

- 7″ × 13″ tooling plate

- 15″ (63 mm) extended column bed

- Extra-rigid column base

- Resettable, zero-adjustable handwheels that can be mounted to the end of the stepper motors to maintain manual control when needed:

- (2) 2″ (51 mm) handwheels on X- and Y-axes

- (1) 2-1/2″ (63 mm) handwheel on Z-axis

- All with laser-engraved aluminum collars

- NOTE: CNC-ready machines cannot be operated manually unless double-shaft stepper motors are installed.

- ¼” Drill Chuck w/ key, #1 Morse arbor with drawbolt

- Pulleys, drive belt, three hexagonal keys, spindle bars, gib removal tool, eight-foot three-wire power cord, and instruction manual

- Oil reservoirs on the X/Y axes and the Z axis help keep critical parts lubricated. These were initially developed for CNC machines that run constantly for hours on end but can benefit manual machines as well

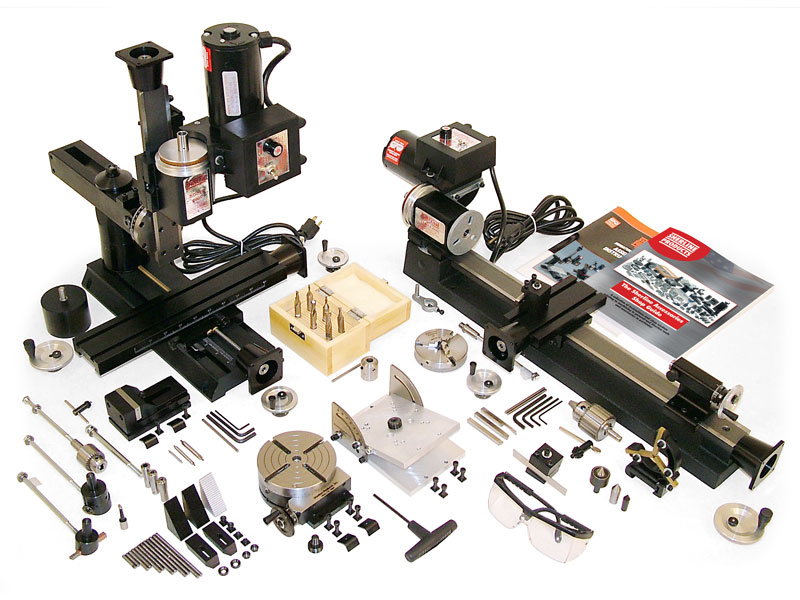

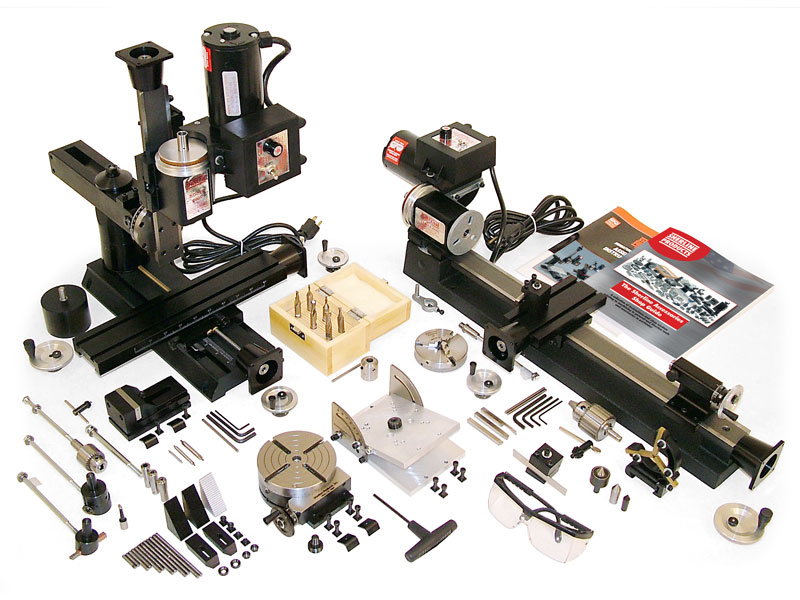

Stepper motor driven 11″ Leasdscrew with Linear Controller

When paired with Sherline’s programmable linear controller, this setup provides a complete, self-contained single-axis CNC power feed. The power supply, mounting screws, and anti-backlash nut (not shown) are included. An additional cable is provided for use with a limit switch or for “daisy-chaining” multiple controllers.

Leadscrew & Handwheel Graduations

Controller Power Supply

The included power supply is compatible with 110–240 VAC and automatically switches between voltages for use in countries with 220–240V power. (The original version of this power supply was 110 VAC only.)

CNC Linear Controller with 15″ Leadscrew

This linear controller package includes a stepper motor mount and a 15" leadscrew for use on Sherline lathes that are not CNC-Ready. The stand-alone controller is programmable through its integrated keypad and directly controls the attached stepper motor, which is mounted to drive the lathe’s leadscrew. (A separate kit with a 24" leadscrew is available for 4400-series lathes—P/N 8880.)

An 8-pin mini-DIN cable allows multiple controllers to be connected in a “daisy-chain” configuration. The controllers can signal each other to operate in sequence, enabling complex multi-axis operations without the need for a computer or master CNC controller. The system can also be used in conjunction with existing CNC controllers. Each unit can store two separate programs, with up to 40 steps per program. For each step, you can define travel distance, direction, feed rate, and whether the sequence pauses or advances automatically.

The linear controller can also be daisy-chained with Sherline’s rotary controller (P/N 8700), allowing coordinated rotary and linear motion. This makes it easy to perform sophisticated operations—such as gear cutting—without any CNC programming knowledge beyond the keypad interface.

Advantages of Using a Power Feed:

Programming is simple and intuitive. Stored programs can be run repeatedly at the push of a button with excellent repeatability and accuracy.

Included with the CNC Linear Controller:

Power Supply Compatibility:

The included power supply operates on 110–240 VAC and automatically adjusts for global use (220–240V). Earlier models of this product shipped with a 110 VAC-only power supply.

CNC Linear Controller with 24″ Leadscrew

This CNC power feed includes a stepper motor mount and a 24" leadscrew for use with Sherline lathes that are not CNC-Ready. The stand-alone controller is programmable through its integrated keypad and directly controls the attached stepper motor, which can be mounted to drive the leadscrew of the lathe.

An 8-pin mini-DIN cable allows multiple controllers to be connected in a “daisy-chain” configuration. Controllers can signal one another to operate in sequence, enabling complex multi-axis movements without requiring a computer or master CNC controller. The controller can also be used in combination with existing CNC systems. Each unit is user-programmable with two independent programs of up to 40 steps each. For each step, you can set travel distance, direction, feed rate, and whether the sequence pauses or proceeds automatically.

The linear controller can also be daisy-chained with Sherline’s rotary controller (P/N 8700) to combine rotary and linear movements. This makes it easy to perform advanced tasks—such as gear cutting—without any CNC programming knowledge beyond the keypad interface.

Advantages of Using a Power Feed:

Programming is quick and straightforward. Stored programs can be executed repeatedly at the touch of a button with high precision.

Included with the CNC Linear Controller:

Power Supply Compatibility:

The included power supply operates on 110–240 VAC and automatically adjusts for international use (220–240V). Earlier versions of this product were supplied with a 110 VAC-only power supply.

CNC Linear Controller – X/Y-Axis Upgrade

This kit upgrades the X- or Y-axis of a manual Sherline milling machine or the crosslide of a Sherline lathe for use with a CNC linear controller. It includes a CNC linear controller and all the components required to convert a manual axis to CNC operation. The linear controller comes with a stepper motor mount for machines that are not CNC-Ready.

The stand-alone controller is programmable via its integrated keypad and controls the attached stepper motor, which can be mounted on the mill’s X- or Y-axis or the lathe’s crosslide. (For lathe leadscrew upgrades, click here for 15" upgrade kits or click here for 24" kits.)

An 8-pin mini-DIN cable allows multiple controllers to be connected in a "daisy-chain" configuration. Controllers can signal one another to run in sequence, enabling complex, multi-axis movements without a computer or master CNC controller. The controller also integrates easily with existing CNC systems. Each controller stores two independent programs with up to 40 steps per program. Each step can define travel distance, direction, feed rate, and whether the sequence pauses or continues automatically.

The linear controller can also be daisy-chained with Sherline’s rotary controller (P/N 8700), allowing combined rotary and linear motion for advanced operations—such as gear cutting—without the need for CNC programming skills beyond simple keypad inputs.

Included with the CNC Linear Controller:

Power Supply Compatibility:

The included power supply is compatible with 110–240 VAC and automatically adjusts for global use (220–240V). Earlier versions of this product shipped with a 110 VAC-only power supply.

CNC Linear Controller – Z-Axis

This stand-alone controller is programmable from its keypad and controls the stepper motor's function to which it is attached.

An 8-pin mini-DIN cable can be used to connect multiple units in a "daisy chain." The units can signal each other to work in sequence, allowing multiple movements to be accomplished without using a computer or master CNC controller. They can also be used in conjunction with existing CNC controllers. The controller is user-programmable with two separate programs of up to 40 operations each. In each block, you can control distance, direction, speed, and whether the program pauses or proceeds to the next block.

The linear controller can also be "daisy-chained" with Sherline's rotary controller to achieve rotary and linear movement combinations. This makes it easy to set up for relatively sophisticated operations like cutting gears without having to know anything about CNC programming beyond what is entered from these simple keypads.

Using a power feed offers several advantages:Programming is quick and simple, and programs are repeated at the touch of a button with high accuracy.

Items included with the CNC Linear Controller:The controller power supply is 110-240VAC compatible. It automatically switches from 110V to 240V for countries with 220-240 volt electrical current. The original power supply that we offered with this product was 110 VAC only.

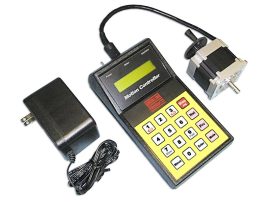

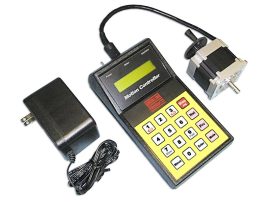

CNC Linear Controller with Stepper Motor

This stand-alone controller is fully programmable via its integrated keypad and directly controls the stepper motor to which it is connected. The stepper motor can be applied to any axis of a CNC-Ready Sherline machine.

An 8-pin mini-DIN cable allows multiple controllers to be connected in a “daisy-chain” configuration. Controllers can signal one another to operate in sequence, enabling complex, multi-axis movements without the need for a computer or master CNC controller. The system can also be used alongside existing CNC controllers. Each controller stores two independent programs, with up to 40 operations per program. For each operation, you can define travel distance, direction, feed rate, and whether the sequence pauses or proceeds to the next step.

The linear controller can also be daisy-chained with Sherline’s rotary controller, enabling coordinated rotary and linear motion. This allows users to easily perform advanced operations—such as gear cutting—without requiring CNC programming skills beyond simple keypad inputs.

Included with the CNC Linear Controller:

Note: To add CNC linear control to an axis on a Sherline machine that does not have a stepper motor mount, see P/N 8850.

Power Supply Compatibility:

The included power supply operates on 110–240 VAC and automatically adjusts for global use (220–240V). Earlier versions of this product shipped with a 110 VAC-only power supply.

36V Closed-Loop Stepper Motor

The 36V stepper motor is a closed-loop motor with an integrated driver, housed in the same NEMA 23 frame as our standard stepper motor. It features built-in LED indicators that display both power and alarm status for easy monitoring.

⚠️ NOTE: The 36V closed-loop stepper motors are sold only as replacement parts for Sherline Accu-Pro machines. They are not available as upgrade components for pre-existing systems.

Stepper Motors

P/N 67127 – Standard Stepper Motor (with Plug)

The standard Sherline stepper motor (P/N 67127) comes pre-wired with six leads into a 5-pin DIN connector that plugs directly into Sherline’s CNC driver boxes and linear or rotary controllers. Simply plug each motor into the corresponding axis cable for a quick, clean setup. This motor is ideal for typical Sherline CNC applications where cutting loads are moderate, such as machining aluminum, brass, plastics, and light cuts in steel.P/N 67130 – Stepper Motor (Without Plug)

P/N 67130 is the same basic motor as P/N 67127 but supplied with six raw wire leads and no connector. It is intended for non-Sherline controllers or custom installations where a different pinout or connector is required.P/N 67126 – High-Torque Stepper Motor

Sherline’s high-torque stepper motor (P/N 67126) uses the same NEMA 23 frame size and 1/4" dual shaft as the standard motor, but delivers over 75% more holding torque. This added torque is especially useful on the Z-axis, where it can better handle the weight of the headstock and motor, and for heavier cuts or higher feed rates. Rated at 2 amps, the high-torque motor is fully compatible with all Sherline CNC machines, including complete CNC systems, the 4-axis driver box, CNC rotary tables, and Sherline linear and rotary controllers. No power supply upgrade is required. [/pane] [pane title="Specifications Comparison"]| Specification | P/N 67127 – Standard | P/N 67126 – High-Torque |

|---|---|---|

| Frame size | NEMA #23 | NEMA #23 |

| Shaft | 1/4" diameter, dual shafts | 1/4" diameter, dual shafts |

| Step angle | 1.8° (200 steps/rev) | 1.8° (200 steps/rev) |

| Holding torque | 0.775 N·m 7.9 kg-cm 109.71 oz-in 6.856 in-lb | 1.35 N·m 13.756 kg-cm 191.17 oz-in 11.948 in-lb |

| Maximum RPM | 530 RPM | 530 RPM |

| Voltage (nominal) | 3.2 V DC | 4.5 V DC |

| Current | 2.0 A/phase | 2.0 A/phase |

| Rotor inertia | 250 g-cm² | 480 g-cm² |

| Axial / radial load (max) | See spec sheet | Axial: 15 N (3.37 lbf) Radial: 75 N (16.86 lbf) |

| Number of leads | 6 leads (with DIN plug on 67127) | 6 leads |

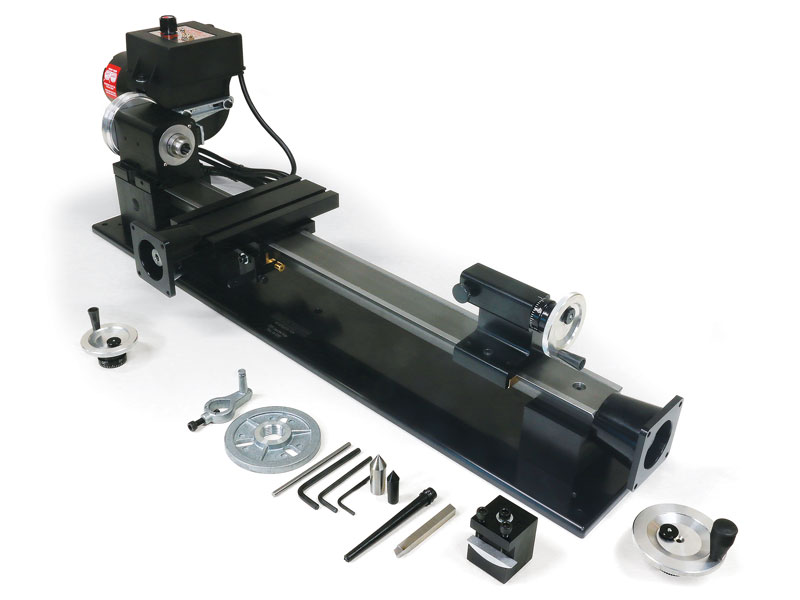

8″ Tabletop Lathe – CNC Ready

The Sherline 8″ CNC Lathe is a precision benchtop machine designed for small, detailed, and accurate turning applications. Built on Sherline’s proven lathe platform, this CNC-ready version includes factory-installed stepper motor mounts on both the X and Z axes – allowing you to add your own stepper motors and controller for complete CNC control.

With a 15″ long bed, 6″ crosslide, and a working diameter capacity of up to 3.5″ over the bed, this lathe provides the versatility needed for prototyping, small-part production, model engineering, R&D, and teaching environments. The rigid aluminum/steel construction, dovetail slides, and adjustable backlash compensation ensure repeatable accuracy on even the smallest parts.

All CNC-ready Sherline lathes include the same high-quality headstock, spindle, and bearings used in our manual models, giving you excellent spindle concentricity for demanding turning operations. The machine still allows for full manual operation when needed – simply turn the handwheels for quick setup or manual machining tasks.

Features:

Ideal Applications:

Note: This is a CNC-ready lathe. Stepper motors and CNC controller are sold separately. For a fully assembled and tested system, see our complete CNC lathes.

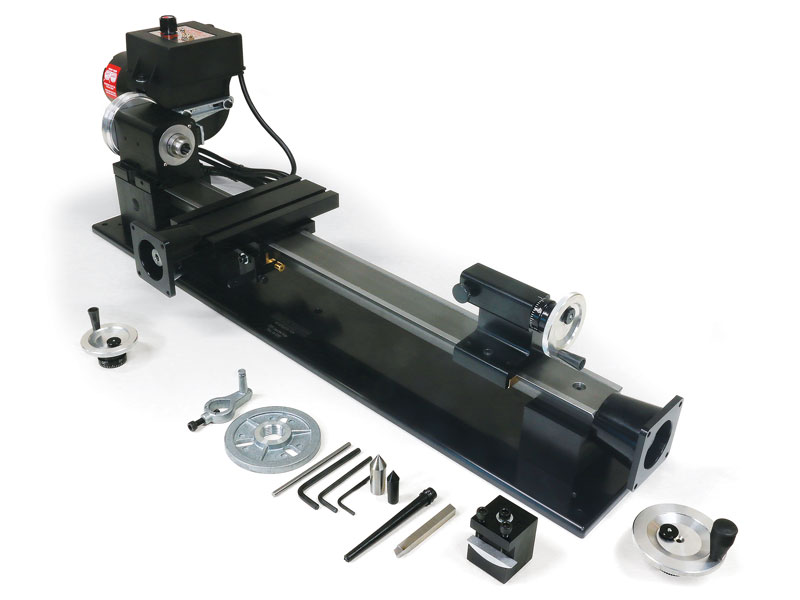

17″ CNC-Ready Lathe

The Sherline 17" CNC Lathe is a precision benchtop machine designed for small, detailed, and accurate turning applications. Built on Sherline’s proven lathe platform, this CNC-ready version includes factory-installed stepper motor mounts on both the X and Z axes - allowing you to add your own stepper motors and controller for complete CNC control.

With a 17" long bed, 8" crosslide, and a working diameter capacity of up to 3.5" over the bed, this lathe provides the versatility needed for prototyping, small-part production, model engineering, R&D, and teaching environments. The rigid aluminum/steel construction, dovetail slides, and adjustable backlash compensation ensure repeatable accuracy on even the smallest parts.

All CNC-ready Sherline lathes include the same high-quality headstock, spindle, and bearings used in our manual models, giving you excellent spindle concentricity for demanding turning operations. The machine still allows for full manual operation when needed - simply turn the handwheels for quick setup or manual machining tasks.

Features:

Ideal Applications:

Note: This is a CNC-ready lathe. Stepper motors and CNC controller are sold separately. For a fully assembled and tested system, see our complete CNC lathes.

10″ Tabletop Mill – CNC-Ready

Our CNC-ready tabletop mill is perfect for the customer looking for a mini CNC milling machine to make small, precision parts. All our milling machines are made in the USA, and our customer service is second to none. Although our machines are small, they can produce high-quality precision parts. Our CNC mill will not only cut wood and plastic but is also rigid and accurate enough to cut aluminum and steel parts. This mill is a desktop-size machine with full-size machine precision and accuracy.

Sherline CNC-ready mills have factory-installed stepper motor mounts in place of the handwheels and are ready to apply stepper motors and computer numeric controls (CNC). CNC-Ready milling machines are not turn-key machines and cannot be used until stepper motors have been installed. All milling machines that are described as “CNC-ready” have stepper motor mounts but do NOT include stepper motors, computer, or CNC software.

Sherline recommends using dual-shaft stepper motors so that handwheels can be applied to the rear shaft for manual control. With that in mind, handwheels for each axis are included with the machine, although you can't use them until you install stepper motors. Sherline offers high-quality stepper motors and CNC options.

You can also find several aftermarket suppliers for motors, drivers, and software to complete the CNC system. You supply the 486 processor or better computer. See our CNC Dealers page for a list of suppliers and links to their home pages.

Notes on ordering a metric millMost of our cutting tools, like center drills, are manufactured in a fractional size. If you have a metric machine with metric holders, like collets or end mill holders, you will need to order fractional holders to accommodate our cutting tools.

Standard Equipment for the 10″ Deluxe Tabletop Mill

12″ CNC-Ready Mill

Our CNC-ready tabletop mill is ideal for customers seeking a compact CNC milling solution for producing small, precision parts. This mill offers full-size machine accuracy in a desktop footprint. Despite its size, it’s capable of cutting wood, plastic, aluminum, and even steel with impressive rigidity and precision.

CNC-ready mills come with factory-installed stepper motor mounts in place of handwheels and are ready for you to add your own stepper motors and CNC controls. Please note: these are not turn-key systems and cannot be operated until motors and controls are installed. CNC-ready machines do not include stepper motors, a computer, or CNC software.

Sherline recommends dual-shaft stepper motors so manual control is still possible using the included handwheels, which mount to the rear shaft once the motors are installed. Sherline also offers high-quality stepper motors and CNC components to complete your system.

Additionally, you can explore various aftermarket suppliers for compatible motors, drivers, and software. Visit our CNC Dealers page for a list of suppliers and links to their websites.

Note on Ordering a Metric Mill – Most Sherline cutting tool, such as center drills, are offered in fractional sizes. If you opt for a metric machine with metric collets or holders, you’ll need to order compatible fractional-size holders to use these tools effectively.

Standard Equipment for the 12″ Deluxe Tabletop Mill

14″ CNC-Ready Mill

The 8-Direction CNC-Ready Milling Machine is one of the most versatile mills Sherline offers. In addition to standard X-, Y-, and Z-axis movement, this model provides five additional directions of headstock adjustment—allowing you to position the spindle for drilling or milling operations from nearly any angle.

With this wide range of movement, the machining possibilities are nearly limitless within the compact work envelope of the machine. The 14″ base also increases Y-axis travel by 2″ compared to the Model 5400 mill, making it a powerful tool for advanced miniature machining applications.

The 8-Direction benchtop mill is ideal for users who need a small, precision milling machine capable of high-accuracy work. Like all Sherline mills, it is made in the USA and supported by unmatched customer service. Despite its compact size, this 14″ benchtop mill is engineered to handle wood, plastic, aluminum, and even steel—delivering full-size machine precision in a desktop footprint.

CNC-ready mills come with factory-installed stepper motor mounts in place of handwheels and are ready for you to add your own stepper motors and CNC controls. Please note: these are not turn-key systems and cannot be operated until motors and controls are installed. CNC-ready machines do not include stepper motors, a computer, or CNC software.

Sherline recommends dual-shaft stepper motors so manual control is still possible using the included handwheels, which mount to the rear shaft once the motors are installed. Sherline also offers high-quality stepper motors and CNC components to complete your system.

Additionally, you can explore various aftermarket suppliers for compatible motors, drivers, and software. Visit our CNC Dealers page for a list of suppliers and links to their websites.

Note on Ordering a Metric Mill – Most Sherline cutting tool, such as center drills, are offered in fractional sizes. If you opt for a metric machine with metric collets or holders, you’ll need to order compatible fractional-size holders to use these tools effectively.

Standard Equipment for the 14″ 8-Direction Tabletop Mill

18″ CNC-Ready Mill

The Sherline NexGen Benchtop Mill is the largest vertical milling machine we offer. As Sherline mills have become increasingly popular in industrial, laboratory, and educational settings, the need for a larger-capacity mill led to the development of the NexGen model. This benchtop mill features an expanded mill base, a longer crosslide table, and an extended column—providing greater work area and capability than our Deluxe 8-Direction Benchtop Mill (Series 2000/2100).

To fully support the extended travel of the column, we’ve increased the cross-section of the column base for added rigidity. To further improve stability during heavy cuts, the column arm no longer swings side to side. However, you still retain full flexibility with 90° rotation to the left and right, as well as in-and-out column movement—giving the NexGen mill a total of seven directions of adjustment, including X, Y, Z, and headstock rotation.

The NexGen mill is ideal for customers seeking a compact, high-precision mini mill for small parts. All Sherline milling machines are made in the USA and backed by exceptional customer support. Despite its small footprint, this 18″ benchtop mill delivers full-size machining accuracy. It’s capable of cutting wood, plastic, aluminum, and even steel with precision and rigidity.

CNC-ready mills come with factory-installed stepper motor mounts in place of handwheels and are ready for you to add your own stepper motors and CNC controls. Please note: these are not turn-key systems and cannot be operated until motors and controls are installed. CNC-ready machines do not include stepper motors, a computer, or CNC software.

Sherline recommends dual-shaft stepper motors so manual control is still possible using the included handwheels, which mount to the rear shaft once the motors are installed. Sherline also offers high-quality stepper motors and CNC components to complete your system.

Additionally, you can explore various aftermarket suppliers for compatible motors, drivers, and software. Visit our CNC Dealers page for a list of suppliers and links to their websites.

Note on Ordering a Metric Mill – Most Sherline cutting tool, such as center drills, are offered in fractional sizes. If you opt for a metric machine with metric collets or holders, you’ll need to order compatible fractional-size holders to use these tools effectively.

Standard Equipment for the 18″ NexGen Tabletop Mill