-

Each insert offers six usable cutting edges:

-

Rotate 120° to access a new edge (3 per side), then

-

Flip the insert for 3 more cutting points on the opposite face

-

-

In comparison, traditional carbide inserts offer only 2–4 cutting edges, making ceramic inserts cost-effective over time, despite the higher upfront cost.

-

Ceramic inserts are brittle and should be used with proper technique to avoid chipping or breakage.

-

Caution: Chips produced during cutting can be extremely hot—even red-hot. Use protective eyewear, gloves, and fire-safe clothing when operating.

-

Some materials, such as tool steel, may form long, stringy chips that wrap around the part ("bird’s nest" effect).

Use a chip brush and stop the machine frequently to clear chips. These chip clusters can ignite if they come in contact with hot chips.

3/8-16 Flange Nut

Thread Type Coarse Finish Black Phosphate Material Grade 8 Diameter 3/8″

3/8″ Drill Chuck with #1 Morse Arbor

Ceramic Insert Tool Holder

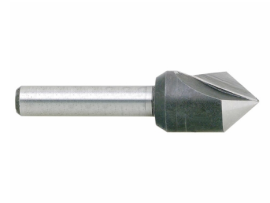

Designed for cutting hard materials like tool steel, this ceramic insert tool holder features a triangular insert mounted at a negative rake angle. The downward tilt of the insert provides proper side clearance, allowing you to use all six cutting edges—three per side—before needing a replacement. The 3/8" shank fits Sherline’s P/N 7600 tool post (not included). A clamp, hold-down screw, and 3/32" hex key are included for secure installation. Replacement inserts are available as (P/N 22659).

Why Use Ceramic Inserts?

Ceramic cutting tools are a powerful addition to the modern machinist’s toolbox. Though more brittle than high-speed steel (HSS) or carbide, ceramic inserts excel at cutting hardened steels and other tough materials, especially at higher spindle speeds. This makes them ideal for jobs that would otherwise be extremely difficult or impossible—such as turning down the shank of an end mill.

This insert’s large nose radius helps achieve an excellent surface finish, particularly when profiling.

Usage Notes & Safety Information

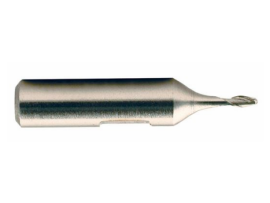

Straight Insert Tool Holder w/55° insert

About the Carbide Inserts

While high-speed steel (HSS) tools remain the primary choice for miniature machine work due to their affordability and ease of resharpening, inserted-tip carbide tools offer significant advantages in specific applications. Carbide inserts excel in cutting harder materials, improving efficiency and tool life—making them invaluable in many professional machining environments.Safety Note

Carbide inserts can produce extremely hot chips and may shatter under stress. Always wear appropriate eye protection and safety gear when using these tools. Certain materials, such as tool steel, may form long, continuous chips that can wrap around the workpiece like steel wool. To minimize this, use a chip brush frequently or pause machining to remove chip buildup. These “bird’s nests” can ignite from hot chips, so maintain a clean workspace near the cutter.