- Powerful 90V DC motor with electronic speed controller

- Silicone dust cover that seals the speed control toggle switch, keeping debris out and extending switch life

- 2.75″ (70mm) × 6.0″ (152mm) crosslide

- 15″ (381mm) steel bed providing 8″ (203mm) between centers

- Adjustable resettable “zero” handwheels: 2.5″ (63 mm) on the leadscrew, and 2″ (51 mm) on the crosslide feed screw. 1-5/8″ (41mm) standard handwheel on the tailstock – each handwheel has laser-engraved aluminum handwheel collars

- Pulleys and drive belt

- Faceplate and lathe dog

- Two dead centers

- Three hex keys

- Single position Tool post

- Sharpened high-speed steel cutting tool

- Eight-foot, three-wire power cord

- Instruction manual

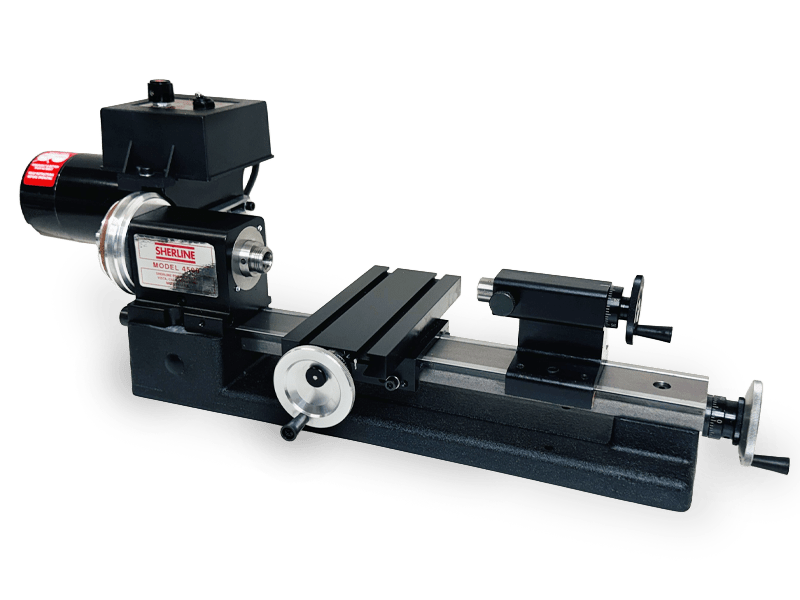

Sherline Precision Jewelers Lathe

The 8″ tabletop lathe is an ideal precision tool for jewelers and gem cutters working on small, detailed components such as rings, settings, mandrels, bezels, bushings, and custom fixtures. It can turn parts up to 3.5″ in diameter over the bed or 1.88″ over the carriage, with 8″ of distance between centers, providing ample capacity for most jewelry and lapidary work without unnecessary machine size.

For jewelry applications, we often recommend the 8″ tabletop lathe over our 17″ model. The additional bed length of the 17″ lathe is rarely needed for typical jeweler or gem-cutting tasks, and its longer layout requires reaching farther to operate the Z-axis handwheel. The compact design of the 8″ lathe keeps both handwheels close to the work area, allowing for greater control, improved ergonomics, and more precise hand-fed cuts during fine finishing operations.

The lathe features an electronic speed control that provides continuously variable spindle speeds from 70 to 2,800 RPM without belt changes, making it easy to dial in the correct speed for delicate materials and small-diameter tools. A secondary pulley position is available when additional low-RPM torque is needed for tougher materials or heavier cuts. Despite its compact footprint, the machine is rigid and stable, delivering the smooth, controlled operation required for jewelry-scale precision.

Typical Jewelry & Gem-Cutting Applications

- Turning and sizing ring blanks and bands

- Machining ring mandrels and expanding mandrels

- Cutting and finishing bezels, settings, and prongs

- Making collet-held parts and small precision components

- Truing and modifying stone setting tools

- Fabricating custom jigs, fixtures, and specialty tools

- Light turning of precious and non-precious metals

- Working with wax, plastic, aluminum, and steel for prototypes and tooling

Designed for jewelers seeking a professional-grade mini lathe, this tabletop machine combines desktop convenience with true machine-tool accuracy. Made in the USA and backed by knowledgeable customer support, it is capable of machining wood, plastic, aluminum, and steel, making it a versatile addition to any jewelry or gem-cutting workshop. Its small size makes it especially well suited for space-limited studios and home shops, and it can be easily stored when not in use.

-

The improper use of machine tools and their accessories can result in serious injury. Before using this tool, thoroughly read the instructions and make sure you understand its proper and safe use.

| Swing Over Bed | 3.50″ (90 mm) |

|---|---|

| Swing Over Carriage | 1.75″ (45 mm) |

| Distance Between Centers | 8.00″ (200 mm) |

| Hole Through Spindle | .405″ (10 mm) |

| Spindle Nose Thread | 3/4″-16 T.P.I. |

| Spindle Nose Taper | #1 Morse |

| Spindle runout of Morse taper | .0005″ or less |

| Travel of Crosslide | 4.25″ (110 mm) |

| Tailstock Spindle Taper | #0 Morse |

| Protractor Graduations | 0° to 45° by 5° |

| Handwheel Graduations | .001″ (.01 mm) |

| Length Overall | 23.5″ (597 mm) |

| Width Overall | 10.5″ (267 mm) |

| Height Overall | 8.5″ (216 mm) |

| Shipping Weight | 24 lb. (10.9 kg |

| Motor | 90 volt DC with electronic speed control that accepts any incoming current from 100VAC to 240 VAC, 50 Hz or 60 Hz.

Click here for motor specifications |

| Spindle Speed Range | 70-2800 RPM continuously variable by electronic speed control |

4000-Series Manual Lathe

Click on the link for the exploded view of the 4000-Series Manual Lathe to help identify replacement parts.

If you are still uncertain please call our customer service representatives for help with this item.

Click the P/Ns below to download a zipped version of the IGS 3D CAD file. You will need to extract the zip file before viewing the files.

4000 Series 8″ Lathe 3D IGS model

4000 Series 8″ Lathe w/1041 3-Jaw Chuck 3D IGS model

You need an IGS viewer to open .igs files. CLICK HERE to download a FREE IGS viewer.

Related products

- Made from 12L14 steel with electroless nickel plating for corrosion resistance

- Tapered body provides greater visual access to the stone during cutting

- ¼" dop hole with 10-32 set screw to secure the dop

- 3/32" locating pin for alignment of angle-cut dops

- Precision-machined with tight tolerances for a secure, accurate fit

- Keyed dop system ensures repeatable orientation and alignment

- Fully compatible with Ultra Tec® brand dops and machines

- High-quality construction - Made in the USA

-

P/N 2078 holds jeweler’s burrs with a 3/32" shank.

-

P/N 2079 is designed for Dremel® tools and other cutters with a 1/8" shank.

- P/N 2080 holds jeweler’s burrs with a 3mm shank.

-

Inch Collets: Part numbers begin with 1160, followed by two digits representing the size in 64ths of an inch.

-

Example: P/N 116013 is 13/64"; P/N 116016 is 1/4" (16/64").

-

-

Metric Collets: Part numbers begin with 1178, followed by two digits representing the size in 0.1 mm increments.

-

Example: P/N 117813 is 1.3 mm.

-

-

Inch sizes from 1/64" to 5/16", in 64th-inch increments.

-

Metric sizes from 0.3 mm to 8.0 mm, in 0.1 mm increments.

Jeweler DOP Holder

Sherline Products, in collaboration with Bryan D. Drummond (Gem Cutter & Goldsmith), has designed this DOP Holder specifically for securely holding lapidary DOP sticks during gemstone cutting. If you already own one of our machines, the holder is designed to thread directly onto our ¾-16 headstock spindle nose. It will also be an essential accessory for our upcoming gem cutting machines.

Compatible with Ultra Tec® Dops This DOP Holder has been precisely engineered with tolerances and a keyed dop system designed for compatibility with Ultra Tec® brand dops which are used on their faceting machines. Many gem cutters use Ultra Tec equipment for flat faceting, and the keyed dop feature provides secure alignment and ease of use, making it a valuable addition to your setup. Sherline does not manufacture dops, but they can be purchased directly from Ultra Tec. Like Sherline, Ultra Tec products are high-quality and Made in the USA. Shop Ultra Tec Dops Features:

Jeweler Burr Holder

These specialized holders were developed at the request of a jewelry design customer. Similar to our standard end mill holders, they feature a longer body with a tapered end, allowing better visibility of the cutter and improved access for working in cavities.

Each holder includes two Tommy bars and one 1/16" hex key.

Individual WW Collets

Collets offer a fast and accurate way to mount cylindrical parts or bar stock in a lathe. Each collet functions like a miniature precision 3-jaw chuck and fits into a tapered adapter mounted in the headstock. A drawbar passes through the headstock and threads into the rear of the collet, pulling it into the adapter. This action causes the collet jaws to close and securely grip the workpiece. Collets are known for their exceptional centering accuracy, but each collet size accommodates only a limited diameter range—typically ±.001" (0.02 mm).

WW Collets vs. Milling Collets

Unlike milling collets, WW collets feature a through-hole, allowing material to pass completely through both the collet and drawbar. The maximum diameter stock that can pass through is 3/16" (4.5 mm), although WW collets are available in sizes up to 5/16" (8.0 mm). Collets larger than the through-hole capacity are sometimes referred to as “pot chucks,” as they are only bored to a depth of approximately .260".

Collet Accuracy

Sherline WW collets are precision-made and have a maximum runout of .002" or less. When the WW collet adapter is properly trued as recommended in the instructions, runout is minimized, providing optimal accuracy. Pot chucks (collets larger than 3/16" or 4.5 mm) are not bored through and may exhibit increased runout if your part extends far beyond the front of the collet.

Logical Part Numbering

Sherline collets are organized by size for easy identification:

Compatibility and Specifications

Sherline WW collets are manufactured in-house to standard WW specifications but are not hardened. The shank diameter is .312–.313", and the thread is .275-40. While some third-party WW collets may not fit properly, Sherline offers an optional .315" adapter and drawbar set (P/N 1163) to accommodate select 8 mm collets from other manufacturers.

Available Sizes

Sherline WW collets are offered in:

Special inch sizes up to .320" can be custom ordered with approximately a 3-week lead time. Please contact us for details.

Quck Order

If you are ordering a lot of different size collets please use the quick order table below to make it easier!

Interchangeable Jaws

Certain delicate parts require gripping with softer jaw materials. Other operations require chuck jaws that do not transmit particles of rust to the part being held. To accommodate these special circumstances, Sherline now offers 2-piece chuck jaws with interchangeable top jaws made from special materials, and bottom master jaws*. In place of the standard hardened or optional unhardened (“soft”) steel 1-piece jaws, these new top jaws are .600” tall and come in soft materials like Delrin, Teflon, and Nylon, plus harder but non-rusting materials like brass and aluminum. The replaceable top jaws are fastened to the hardened steel bottom jaws with two countersunk socket head screws. They are not stepped so the customer can machine them for custom holding applications. Other materials are available by request.

*Please note that you must purchase the bottom master jaws before you can use the top jaws.

Tall Top JawsWe also offer taller jaws with heights of 1” and 1-1/2”. The tall jaws are made of aluminum and mild steel. These taller jaws were developed for a customer who uses our lathe for custom jewelry design and can be machined to hold custom work, as seen in the photo to the right.

About Top-Jaw Custom Orders See the Top-Jaw Custom Orders tab below to design your own chuck jaws.NOTE: To customers who are buying these jaws for an existing chuck, please measure the width of your current chuck jaws with a pair of mics so we can grind your master jaws to match. State your current jaw width in the comments box below. For first-time buyers who are buying a new chuck with these Master jaws, your jaws will be ground to match your chuck. The prices shown are for the jaws only (new chuck is not included).