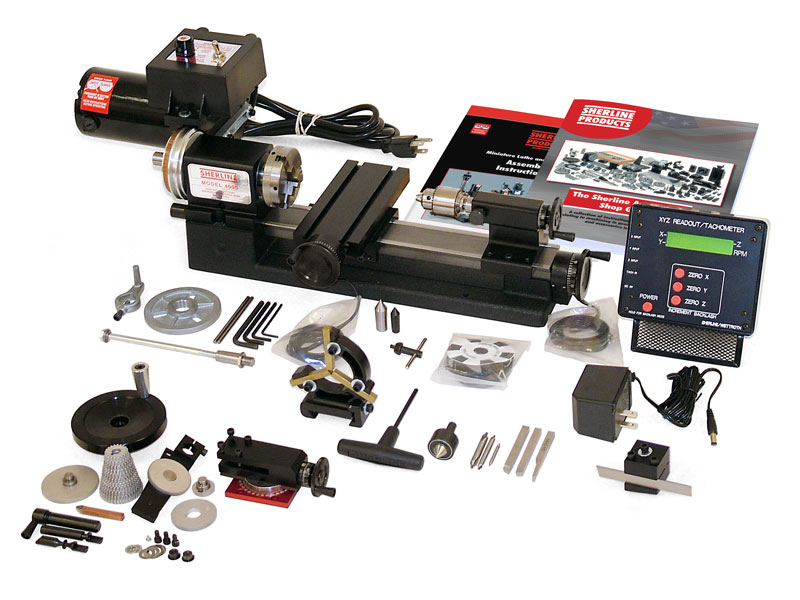

8″ Tabletop Lathe with DRO

Our 8″ DRO Benchtop lathes includes a digital readout box and specialized handwheels with built-in electronic encoders that replace the standard handwheels (standard handwheels are not included with the DRO option). These DRO handwheels interface with the readout box, which translates handwheel movement into precise digital readings for each axis. Each axis can be zeroed at any time with the push of a button, and the DRO continuously displays spindle RPM whenever the motor is running. The readout is compatible with both inch and metric machines.

This compact DRO lathe is ideal for customers who need a small-format machine capable of producing highly accurate, precision parts. Proudly made in the USA, all our lathes are backed by exceptional customer support. Despite its desktop size, this machine delivers full-size performance – capable of cutting wood, plastic, aluminum, and even steel with excellent rigidity and accuracy.

Using the DRO System

The DRO displays each axis position relative to a zero point you set.

- Inch models show position to 0.0005″ (three and a half decimal places)

- Metric models show position to 0.01 mm

The system supports both ball screw and leadscrew machines. As well as the ability to use Metric DROs on inch machines or inch DROs on metric machines. It features six selectable modes based on machine type (mill or lathe), screw type (leadscrew or ball screw), and preferred display units (inch or metric). For setup instructions, refer to the official DRO Mode Instructions.

You can electronically compensate for backlash by inputting the measured backlash value for each axis. When the direction of handwheel rotation reverses, the DRO subtracts the backlash before updating the position – eliminating common errors and making it easier to track travel distance and direction. The power supply automatically switches between 120V and 240V, making it suitable for use in countries with 220–240V electrical current. A socket adapter may be required outside North America.

Features of the 8″ Benchtop Lathe

- 15″ (381 mm) steel bed giving 8″ (203 mm) between centers

- Maximum diameter over bed: 3.50″ (90 mm)

- Crosslide travel: 2.75″ × 6.00″ (70 mm × 152 mm)

- 90 V DC motor with electronic speed control – continuously variable 70–2,800 RPM (no belt changes required)*

- DRO handwheels on leadscrew and crosslide

- DRO (Digital Readout) – precise, repeatable positioning, improving accuracy over handwheel-only control

* Not included with lathe without motor and speed control

What’s Included

- DRO readout box, DRO-compatible handwheels / encoder setup

- Pulleys, drive belt, faceplate, lathe dog

- Two dead centers

- Three hex keys

- Standard tool post

- Sharpened high-speed steel cutting tool

- Grounded 3-wire power cord (8 ft)

- Instruction manual

-

| Swing Over Bed | 3.50″ (90 mm) |

|---|---|

| Swing Over Carriage | 1.75″ (45 mm) |

| Distance Between Centers | 8.00″ (200 mm) |

| Hole Through Spindle | .405″ (10 mm) |

| Spindle Nose Thread | 3/4″-16 T.P.I. |

| Spindle Nose Taper | #1 Morse |

| Spindle runout of Morse taper | .0005″ or less |

| Travel of Crosslide | 4.25″ (110 mm) |

| Tailstock Spindle Taper | #0 Morse |

| Protractor Graduations | 0° to 45° by 5° |

| Handwheel Graduations | .001″ (.01 mm) |

| Length Overall | 23.5″ (597 mm) |

| Width Overall | 10.5″ (267 mm) |

| Height Overall | 8.5″ (216 mm) |

| Shipping Weight | 24 lb. (10.9 kg |

| Motor | 90 volt DC with electronic speed control that accepts any incoming current from 100VAC to 240 VAC, 50 Hz or 60 Hz.

Click here for motor specifications |

| Spindle Speed Range | 70-2800 RPM continuously variable by electronic speed control |

4000-Series Manual Lathe

Click on the link for the exploded view of the 4000-Series Manual Lathe to help identify replacement parts.

If you are still uncertain please call our customer service representatives for help with this item.

|

|

|

|---|---|---|

| 4000 (4100) | 4400 (4410) | |

| Swing over bed | 3.50″ (90 mm) | 3.50″ (90 mm) |

| Swing over carriage | 1.75″ (44.5 mm) | 1.75″ (44.5 mm) |

| Distance between centers | 8.00″ (200 mm) | 17.00″ (430 mm) |

| Hole through spindle | .405″ (10 mm) | .405″ (10 mm) |

| Spindle nose thread | 3/4-16 T.P.I. | 3/4-16 T.P.I. |

| Spindle nose taper | #1 Morse | #1 Morse |

| Spindle runout of Morse taper | 0005″ or less | .0005″ or less |

| Travel of crosslide | 4.25″ (110 mm) | 4.25″ (110 mm) |

| Tailstock spindle taper | #0 Morse | #0 Morse |

| Tailstock spindle travel | 1.75″ (44.5 mm) | 1.75″ (44.5 mm) |

| Protractor graduations | 0° to 45° by 5° | 0° to 45° by 5° |

| Handwheel graduations | 001″ (.01 mm) | 001″ (.01 mm) |

| Handwheel type | Standard Handwheels | Zero Adjustable Handwheels (With the exception of DRO machines, which come with DRO handwheels) |

| Electronically controlled spindle speed range | 70 to 2,800 RPM | 70 to 2,800 RPM |

| Length overall | 23″ (584 mm) | 32.5″ (826 mm) |

| Width overall | 10.25″ (260 mm) | 10.55″ (267 mm) |

| Height overall | 8″ (203 mm) | 8.5″ (216 mm) |

| Shipping weight | 24 lb. (10.9 kg) | 30 lb. (13.6 kg) |

| Motor Specs | ||

| Input voltage | 100 to 240 VAC, 50 or 60 Hz | |

| Output to motor | 90 VDC | |

| Current draw | .5 to 15 amps, depending on the load | |

| No-load output shaft speed | 6000 RPM (no pulley) | |

| Click here for more detailed specs | ||

| Spindle Specs | ||

| Spindle End play (factory adjustment of preload) |

.0002″ (.005 mm) or less, normal pulleys | |

| Runout at nose | .0005″ (0.013 mm) or less | |

| Bearings | Two 20 mm lifetime lubricated ball bearings with adjustable preload | |

Related products

Thread-Cutting Attachment

A key advantage of owning a lathe is the ability to machine threads. While taps and dies can cut many threads, acquiring a comprehensive tap and die set to cover all non-standard thread sizes can be costly. Sherline provides a unique and versatile thread-cutting attachment for its lathe. This affordable attachment enables you to machine thirty-six different unified thread pitches (ranging from 80 to 5 threads per inch) and twenty-eight different metric thread pitches (ranging from .25 to 2.0 mm). It also allows for both left-hand and right-hand threading. A 60° carbide cutting tool is included, but you can also grind a standard high-speed steel tool to cut various thread forms at any pitch diameter. This versatility allows you to machine both standard and non-standard inside or outside threads, as long as they fall within the lathe’s size limitations.

Note: Ensure you lubricate the gears with light oil before using the threading attachment.

The attachment includes:

- 15 aluminum gears

- Mounting brackets

- Engagement mechanism

- 4.00" (102 mm) handwheel

Thread cutting on the Sherline lathe is accomplished by gearing the spindle to the leadscrew. As the spindle is rotated using the handwheel mounted on the headstock spindle, the tool advances according to the gear ratio. Once the tool reaches the end of its movement, simply stop cranking, reverse the tool, and turn the spindle in the opposite direction until the tool passes its starting point. Reset the tool, and you’re ready for the next pass. It’s as straightforward as tapping! By using the supplied 127-tooth gear, you can cut true metric threads on an inch lathe or true inch threads on a metric lathe.

⚠️ Note: The thread-cutting attachment is not compatible with the 3C Headstock.

Adapting the Leadscrew Engagement Lever for Use with Digital Readout (DRO)

If you plan to use the leadscrew engagement lever with the Thread Cutting Attachment in conjunction with a Digital Readout (DRO), you will need to equip your lathe with the DRO sliding shaft (sold separately) for proper leadscrew engagement.Gear Selection Calculator

The Sherline Thread Attachment Calculator, created by Joo Beng Koh of Singapore, automates gear selection based on your desired thread count. Originally shared on the Sherline Lathe & Mill Facebook Group, Joo Beng graciously allowed us to feature this tool on our website. The calculator simplifies the setup process, particularly for users who frequently change their thread specifications.

For instructions, select the desired parameters in the light yellow fields, and the corresponding gear selections will appear in the green boxes. An accompanying image shows the correct gear placement along with step-by-step guidance for installation. This tool has greatly improved the process for Joo Beng and can help others as well.

Click here for Joo Beng Koh's Sherline Thread Attachment Calculator.

More Calculators

Visit our Calculators page to explore additional tools for gear tooth and thread calculations, including calculators for thread counts, helical gears, conversions, and more.