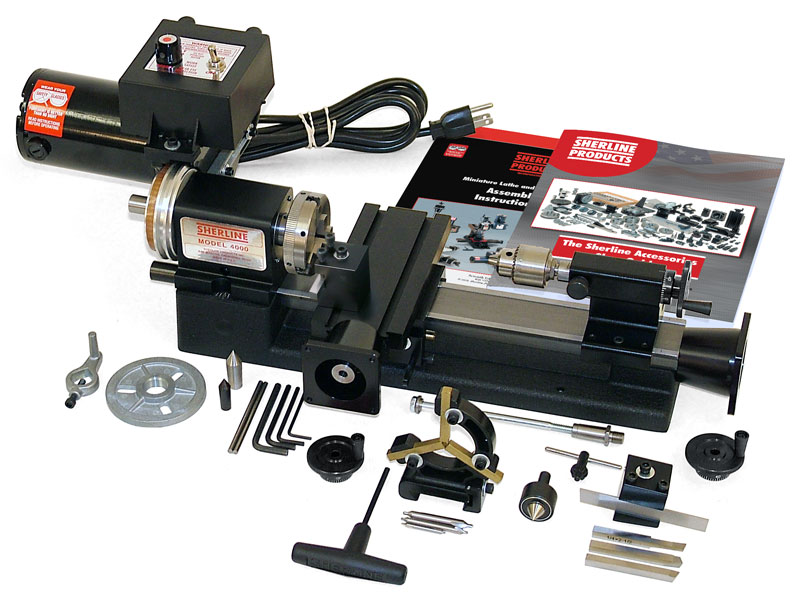

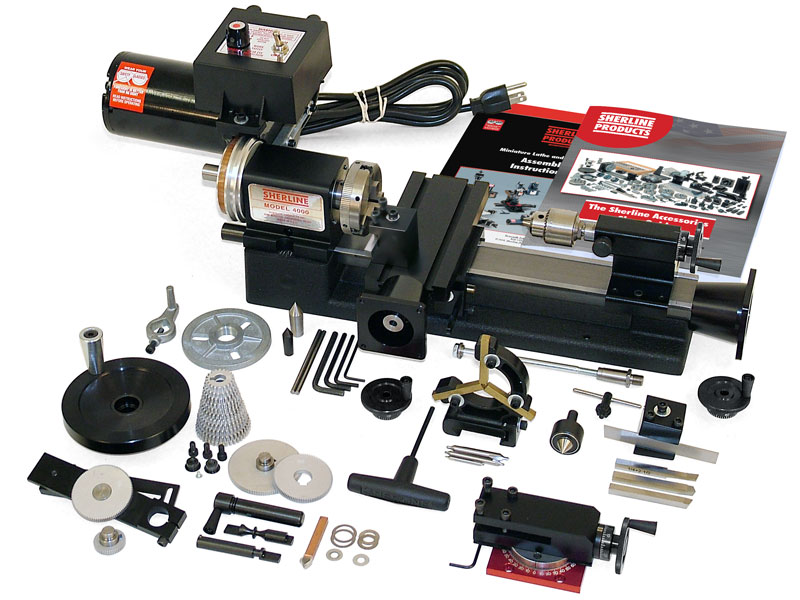

8″ Tabletop Lathe – CNC Ready

The Sherline 8″ CNC Lathe is a precision benchtop machine designed for small, detailed, and accurate turning applications. Built on Sherline’s proven lathe platform, this CNC-ready version includes factory-installed stepper motor mounts on both the X and Z axes – allowing you to add your own stepper motors and controller for complete CNC control.

With a 15″ long bed, 6″ crosslide, and a working diameter capacity of up to 3.5″ over the bed, this lathe provides the versatility needed for prototyping, small-part production, model engineering, R&D, and teaching environments. The rigid aluminum/steel construction, dovetail slides, and adjustable backlash compensation ensure repeatable accuracy on even the smallest parts.

All CNC-ready Sherline lathes include the same high-quality headstock, spindle, and bearings used in our manual models, giving you excellent spindle concentricity for demanding turning operations. The machine still allows for full manual operation when needed – simply turn the handwheels for quick setup or manual machining tasks.

Features:

- CNC-ready with factory-installed stepper motor mounts (X and Z axes)

- Turns parts up to 3.5″ (90 mm) diameter over the bed

- 15″ (381 mm) bed provides extended travel for longer workpieces

- 6″ (152 mm) crosslide for increased tool reach

- Precision-machined dovetail slides with adjustable gibs and backlash

- High-accuracy spindle and headstock used across all Sherline lathes

- Manual control possible with included handwheels

- Compatible with Sherline’s full line of accessories

- Made in the USA

Ideal Applications:

- Model making and miniatures

- Prototyping and custom part production

- Educational CNC training programs

- Hobbyist and light industrial use

Note: This is a CNC-ready lathe. Stepper motors and CNC controller are sold separately. For a fully assembled and tested system, see our complete CNC lathes.

-

| Swing Over Bed | 3.50″ (90 mm) |

|---|---|

| Swing Over Carriage | 1.75″ (45 mm) |

| Distance Between Centers | 8.00″ (200 mm) |

| Hole Through Spindle | .405″ (10 mm) |

| Spindle Nose Thread | 3/4″-16 T.P.I. |

| Spindle Nose Taper | #1 Morse |

| Spindle runout of Morse taper | .0005″ or less |

| Travel of Crosslide | 4.25″ (110 mm) |

| Tailstock Spindle Taper | #0 Morse |

| Protractor Graduations | 0° to 45° by 5° |

| Handwheel Graduations | .001″ (.01 mm) |

| Length Overall | 23.5″ (597 mm) |

| Width Overall | 10.5″ (267 mm) |

| Height Overall | 8.5″ (216 mm) |

| Shipping Weight | 24 lb. (10.9 kg |

| Motor | 90 volt DC with electronic speed control that accepts any incoming current from 100VAC to 240 VAC, 50 Hz or 60 Hz.

Click here for motor specifications |

| Spindle Speed Range | 70-2800 RPM continuously variable by electronic speed control |

4000-Series CNC-Ready Lathe

Click on the link for the exploded view of the 4000-Series CNC-Ready Lathe to help identify replacement parts.

If you are still uncertain please call our customer service representatives for help with this item.

Click the P/Ns below to download a zipped version of the IGS 3D CAD file. You will need to extract the zip file before viewing the files.

4000 Series 8″ Lathe CNC-Ready 3D IGS model

You need an IGS viewer to open .igs files. CLICK HERE to download a FREE IGS viewer.

|

|

|

|---|---|---|

| 4000 (4100) | 4400 (4410) | |

| Swing over bed | 3.50″ (90 mm) | 3.50″ (90 mm) |

| Swing over carriage | 1.75″ (44.5 mm) | 1.75″ (44.5 mm) |

| Distance between centers | 8.00″ (200 mm) | 17.00″ (430 mm) |

| Hole through spindle | .405″ (10 mm) | .405″ (10 mm) |

| Spindle nose thread | 3/4-16 T.P.I. | 3/4-16 T.P.I. |

| Spindle nose taper | #1 Morse | #1 Morse |

| Spindle runout of Morse taper | 0005″ or less | .0005″ or less |

| Travel of crosslide | 4.25″ (110 mm) | 4.25″ (110 mm) |

| Tailstock spindle taper | #0 Morse | #0 Morse |

| Tailstock spindle travel | 1.75″ (44.5 mm) | 1.75″ (44.5 mm) |

| Protractor graduations | 0° to 45° by 5° | 0° to 45° by 5° |

| Handwheel graduations | 001″ (.01 mm) | 001″ (.01 mm) |

| Handwheel type | Standard Handwheels | Zero Adjustable Handwheels (With the exception of DRO machines, which come with DRO handwheels) |

| Electronically controlled spindle speed range | 70 to 2,800 RPM | 70 to 2,800 RPM |

| Length overall | 23″ (584 mm) | 32.5″ (826 mm) |

| Width overall | 10.25″ (260 mm) | 10.55″ (267 mm) |

| Height overall | 8″ (203 mm) | 8.5″ (216 mm) |

| Shipping weight | 24 lb. (10.9 kg) | 30 lb. (13.6 kg) |

| Motor Specs | ||

| Input voltage | 100 to 240 VAC, 50 or 60 Hz | |

| Output to motor | 90 VDC | |

| Current draw | .5 to 15 amps, depending on the load | |

| No-load output shaft speed | 6000 RPM (no pulley) | |

| Click here for more detailed specs | ||

| Spindle Specs | ||

| Spindle End play (factory adjustment of preload) |

.0002″ (.005 mm) or less, normal pulleys | |

| Runout at nose | .0005″ (0.013 mm) or less | |

| Bearings | Two 20 mm lifetime lubricated ball bearings with adjustable preload | |

Related products

- NEMA 23 frame size – fits Sherline CNC-ready mills, lathes, and rotary tables.

- Dual-shaft design – both ends of the shaft are usable; flats are ground on each end for secure attachment of handwheels and couplings.

- Standard step angle – 1.8° per step (200 steps/rev) for precise motion control.

- 2.0 A/phase – both motors are rated at 2.0 amps and work with existing Sherline CNC power supplies and driver electronics.

- 6-lead wiring – allows use in a variety of bipolar or unipolar configurations (see spec sheets for wiring diagrams).

- Designed for Sherline CNC – plug-and-play with Sherline driver boxes and motion controllers when used with the supplied connectors.

- Coupler requirement: Because of the increased torque, the high-torque motor (P/N 67126) must be used with the updated CNC coupling (P/N 671052). This coupling replaces the older 3-slot coupling (P/N 67105).

- Motor mounts: When used with a Sherline stepper motor mount (P/N 67101), be sure that the shaft entering the coupling has a flat aligned with the set screw. Tightening against the round shaft can damage the shaft and make removal difficult.

- Handwheel use: The dual-shaft design lets you mount a handwheel on the rear shaft for manual operation when the drivers are powered down. When the motors are energized, they hold position and cannot be moved easily by hand.

- Controller compatibility: P/N 67127 with the 5-pin DIN plug is designed to plug directly into Sherline’s 4-axis driver box, CNC systems, and linear and rotary controllers. P/N 67130 (no plug) is intended for non-Sherline or custom controllers.

Stepper Motors

P/N 67127 – Standard Stepper Motor (with Plug)

The standard Sherline stepper motor (P/N 67127) comes pre-wired with six leads into a 5-pin DIN connector that plugs directly into Sherline’s CNC driver boxes and linear or rotary controllers. Simply plug each motor into the corresponding axis cable for a quick, clean setup. This motor is ideal for typical Sherline CNC applications where cutting loads are moderate, such as machining aluminum, brass, plastics, and light cuts in steel.P/N 67130 – Stepper Motor (Without Plug)

P/N 67130 is the same basic motor as P/N 67127 but supplied with six raw wire leads and no connector. It is intended for non-Sherline controllers or custom installations where a different pinout or connector is required.P/N 67126 – High-Torque Stepper Motor

Sherline’s high-torque stepper motor (P/N 67126) uses the same NEMA 23 frame size and 1/4" dual shaft as the standard motor, but delivers over 75% more holding torque. This added torque is especially useful on the Z-axis, where it can better handle the weight of the headstock and motor, and for heavier cuts or higher feed rates. Rated at 2 amps, the high-torque motor is fully compatible with all Sherline CNC machines, including complete CNC systems, the 4-axis driver box, CNC rotary tables, and Sherline linear and rotary controllers. No power supply upgrade is required. [/pane] [pane title="Specifications Comparison"]| Specification | P/N 67127 – Standard | P/N 67126 – High-Torque |

|---|---|---|

| Frame size | NEMA #23 | NEMA #23 |

| Shaft | 1/4" diameter, dual shafts | 1/4" diameter, dual shafts |

| Step angle | 1.8° (200 steps/rev) | 1.8° (200 steps/rev) |

| Holding torque | 0.775 N·m 7.9 kg-cm 109.71 oz-in 6.856 in-lb | 1.35 N·m 13.756 kg-cm 191.17 oz-in 11.948 in-lb |

| Maximum RPM | 530 RPM | 530 RPM |

| Voltage (nominal) | 3.2 V DC | 4.5 V DC |

| Current | 2.0 A/phase | 2.0 A/phase |

| Rotor inertia | 250 g-cm² | 480 g-cm² |

| Axial / radial load (max) | See spec sheet | Axial: 15 N (3.37 lbf) Radial: 75 N (16.86 lbf) |

| Number of leads | 6 leads (with DIN plug on 67127) | 6 leads |