90° 47TPI Straight Knurl

BRAND FORM ROLL STYLE Circular Pitch TOOTH PATTERN STRAIGHT TOOL MATERIAL High Speed Steel DIAMETER 1/2″ PITCH 47 WIDTH 3/16″ HOLE SIZE 3/16″ FINISH COATING Lapped Tooth Finish HARDNESS 58 to 60 RC NORMAL CIRCULAR TPI 47 SERIES EP WHEEL … Continued

1/4″ HSS Tool Blank Set

Lathe tools—also known as tool bits—are the cutting tools used for turning, facing, and other operations on a lathe. The most commonly used are high-speed steel (HSS) tools, which are suitable for machining a wide range of materials including wood, plastic, aluminum, brass, and steel. HSS tools maintain their hardness at temperatures up to 1000°F (588°C), making proper depth of cut, cutting speed, and feed rate essential for optimal performance.

One of the key advantages of HSS tools is how easily they can be resharpened using a standard aluminum oxide grinding wheel. Once sharpened, they retain a keen cutting edge through extended use.

Each Sherline lathe comes with a pre-sharpened 1/4" HSS cutting tool. Pre-ground tool sets—featuring right-hand, left-hand, and boring tools—are also available. However, for long-term savings and flexibility, learning to grind your own tools from blanks is recommended. Custom-shaped tools can be saved for repeat jobs or re-ground for new applications.

Slitting Saws

Each saw blade is 2" in diameter with a 1/2" hole. The saw blades come in varying thicknesses and teeth counts. They require the slitting saw holder, which is held in the spindle with a drawbolt that pulls the holder up into the Morse #1 taper.

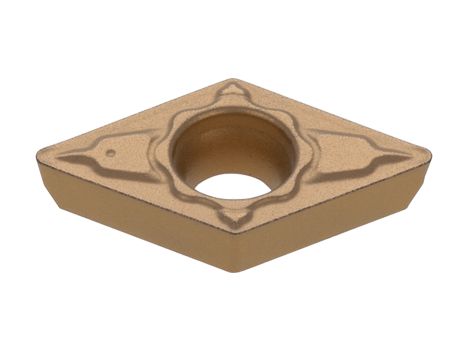

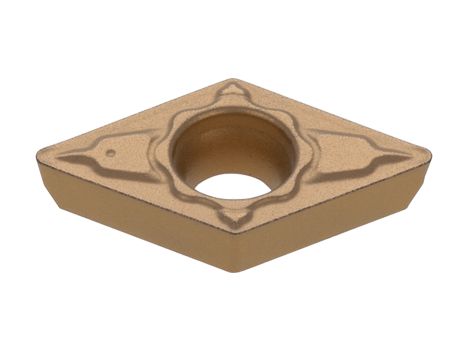

55° Carbide Insert

While not inexpensive, carbide inserts offer excellent value—each insert provides four cutting edges, significantly reducing the need for frequent sharpening and saving valuable time.

Carbide cutters perform well on hard-to-machine materials like cold-rolled steel and are also effective on aluminum, brass, and leaded steels, offering exceptional durability. However, for the finest finishes on softer metals, a well-sharpened high-speed steel tool still delivers superior results.

This is the 10-pack of replacement carbide inserts for the following tool holders:

55° Carbide Insert-10 Pack

While not inexpensive, carbide inserts offer excellent value—each insert provides four cutting edges, significantly reducing the need for frequent sharpening and saving valuable time.

Carbide cutters perform well on hard-to-machine materials like cold-rolled steel and are also effective on aluminum, brass, and leaded steels, offering exceptional durability. However, for the finest finishes on softer metals, a well-sharpened high-speed steel tool still delivers superior results.

This is the 10-pack of replacement carbide inserts for the following tool holders:

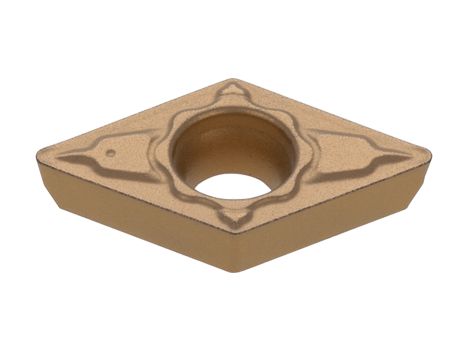

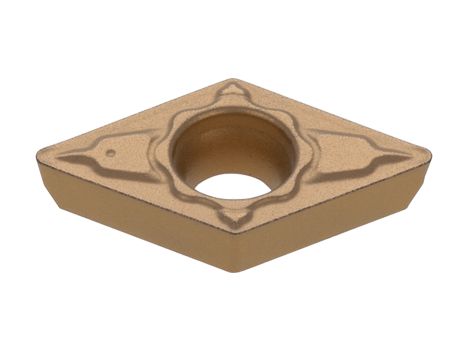

80° Carbide Insert

While carbide inserts may have a higher upfront cost, they offer excellent value by providing four usable cutting edges per insert and significantly reducing time spent on tool sharpening.

Carbide cutters excel at machining difficult materials such as cold-rolled steel, stainless steel, and bronze, delivering consistent performance and long tool life. They are also compatible with aluminum, brass, and leaded steels—though for these softer materials, a finely honed high-speed steel tool may still yield the best surface finish.

This is the 10-pack of replacement carbide inserts for the following tool holders:

80° Carbide Insert-10 Pack

While carbide inserts may have a higher upfront cost, they offer excellent value by providing four usable cutting edges per insert and significantly reducing time spent on tool sharpening.

Carbide cutters excel at machining difficult materials such as cold-rolled steel, stainless steel, and bronze, delivering consistent performance and long tool life. They are also compatible with aluminum, brass, and leaded steels—though for these softer materials, a finely honed high-speed steel tool may still yield the best surface finish.

This is the 10-pack of replacement carbide inserts for the following tool holders:

Carbide Inserts (thread, groove)

These Carbide inserts are used in the Insert Tool Holder and are used for either threading or grooving.

Thread Cutting

- 60° threading insert for cutting outside threads (P/N 22675)

- .031" insert (P/N 2269)

- .062" insert (P/N 2270)

- .094" insert (P/N 22694)

- .125" insert (P/N 22695)

- .031" radius insert (P/N 22692)

- .062" radius insert (P/N 22693)

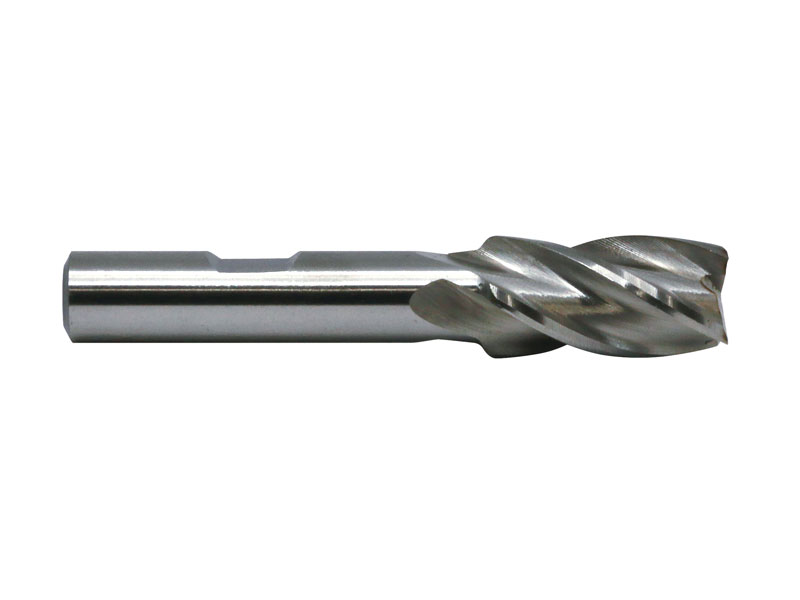

1/4″ 3-Flute End Mill Set

3/8″ Double-Ended End Mill Sets

These precision 3/8″ shank double-ended end mill sets are a versatile and budget-friendly choice for general milling work. Double-ended cutters give you two cutting ends in one tool, doubling your productivity and value. Each cutter features a flat section on the shank for secure clamping in a 3/8″ end mill holder.

Both sets include six popular diameters: 1/8″, 5/32″, 3/16″, 1/4″, 5/16″ and 3/8″.

7400 – 2-Flute Set

Ideal for softer materials such as aluminum, these 2-flute cutters resist clogging and provide smooth chip evacuation.

7401 – 4-Flute Set

With four cutting edges, this set offers increased cutting contact and is better suited for harder materials like steel.

Each set includes a wooden storage block to protect your cutters when not in use

CAUTION: Unlike a drill bit that looks similar, end mills are sharpened on the edges as well as the tip. These sharp edges demand a lot of respect when being handled and used! Also, to keep them sharp, store them in the block provided or individually protected in your toolbox.

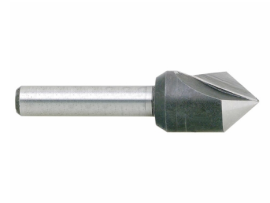

3-piece Center Drill Set

Center drills are essential for accurately drilling starter holes in the ends of workpieces, particularly when mounting stock between centers on a lathe. Each drill creates a small pilot hole followed by a 60° countersink, which provides a seating surface for the 60° point of the lathe center.

In milling applications, center drills are commonly used to start holes precisely. The exact hole location can be dialed in using the mill’s calibrated handwheels, and the center drill ensures the hole begins accurately without drifting.

This set includes three double-ended, high-speed steel (HSS) center drills:

-

#1 drill: 1/8" shank

-

#2 drill: 3/16" shank

-

#3 drill: 1/4" shank

The larger shank diameter of a center drill ensures the tip remains centered, reducing the risk of the drill "walking" as the hole is started. After the center drill has established the starter hole, it is replaced with a standard drill bit to complete the hole to the desired diameter.

⚠️ CAUTION: Always use a suitable cutting lubricant and back the drill out frequently during use. This prevents the delicate tip from overheating or breaking off.

Boring Tools

These high-speed steel cutting tools are designed specifically for use with the Sherline boring head and feature a 3/8" (9.5 mm) diameter shank.

-

P/N 3061 is suited for holes with a minimum diameter of 1/4" (6.4 mm) and a maximum cutting depth of 0.600" (15.2 mm).

-

P/N 3063 works with a minimum hole diameter of 5/16" (7.9 mm) and provides up to 1.00" (25 mm) of cutting depth.

-

P/N 3064 also fits a 5/16" (7.9 mm) minimum hole but offers an extended 1.5" (38.1 mm) reach.

If needed, the tools can be ground to fit smaller hole diameters. They may also be used in the 3/8" round-hole tool post on a lathe for boring operations. Each tool includes a ground flat on the shank to provide a secure surface for the boring head setscrew.