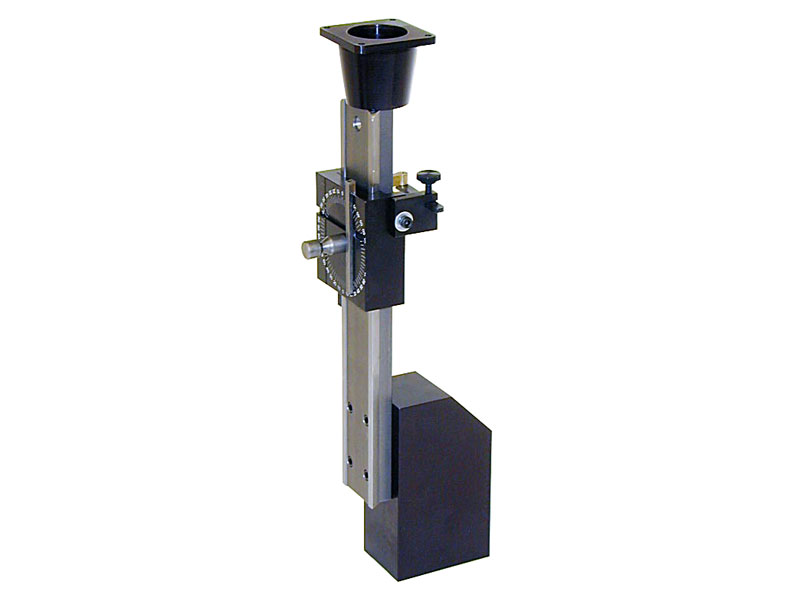

Mill Column – CNC Ready

NOTE: This column is for a mill, if you want to put this column on a lathe click here

-

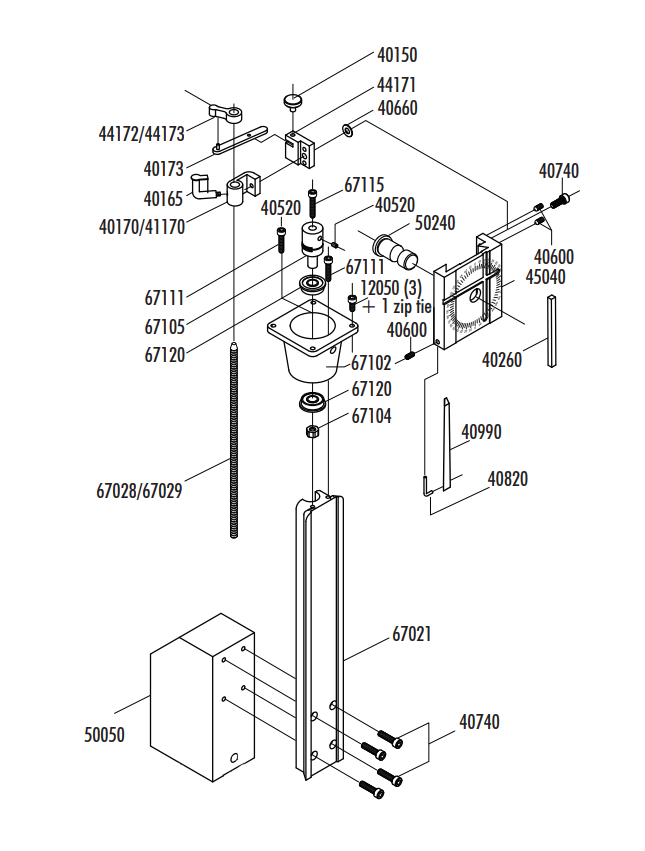

| Part No. | Description | Quantity |

|---|---|---|

| 12050 | 8-32 x 3/8″ SHCS | 3 |

| 3400 3410 |

2.5″ Z Axis Handwheel (Inch) 2.5″ Z Axis Handwheel (Metric) |

1 |

| 4017ZOL 4117ZOL |

Z-Axis Backlash Adjustment Upgrade (Inch) Z-Axis Backlash Adjustment Upgrade (Metric) |

1 |

| 40260 | Head Key | 1 |

| 40600 | 10-32 x 1/4″ Flat Point Set Screw | 1 |

| 40660 | #10 Washer 3/16 | 1 |

| 40740 | 10-32 x 7/8″ SHCS | 4 |

| 40820 | Gib Lock | 1 |

| 40990 | Saddle Gib | 1 |

| 45040 | Column Saddle | 1 |

| 50050 | Mill Column Base | 1 |

| 50220 | 1/4-20 x 1-3/4″ SHCS | 2 |

| 50240 | Pivot Pin | 1 |

| 67021 | CNC Mill Column Bed | 1 |

| 67028 67029 |

Column Lead Screw (Inch) Column Lead Screw (Metric) |

1 |

| 67102 | Stepper Motor Mount | 1 |

| 67104 | CNC Preload Nut – Right Hand | 1 |

| 671052 | CNC Coupling | 1 |

| 67111 | 8-32 x 7/8″ SHCS | 2 |

| 67115 | 5-40 x 7/8″ SHCS | 1 |

| 67120 | Stepper Motor Preload Bearing | 2 |

| 76140 | 5/64″ Hex Key | 1 |

Related products

-

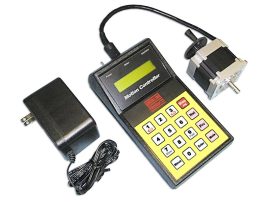

Linear controller with keypad

-

Power supply

-

#23 frame size stepper motor

-

Cables

-

Complete instructions

- NEMA 23 frame size – fits Sherline CNC-ready mills, lathes, and rotary tables.

- Dual-shaft design – both ends of the shaft are usable; flats are ground on each end for secure attachment of handwheels and couplings.

- Standard step angle – 1.8° per step (200 steps/rev) for precise motion control.

- 2.0 A/phase – both motors are rated at 2.0 amps and work with existing Sherline CNC power supplies and driver electronics.

- 6-lead wiring – allows use in a variety of bipolar or unipolar configurations (see spec sheets for wiring diagrams).

- Designed for Sherline CNC – plug-and-play with Sherline driver boxes and motion controllers when used with the supplied connectors.

- Coupler requirement: Because of the increased torque, the high-torque motor (P/N 67126) must be used with the updated CNC coupling (P/N 671052). This coupling replaces the older 3-slot coupling (P/N 67105).

- Motor mounts: When used with a Sherline stepper motor mount (P/N 67101), be sure that the shaft entering the coupling has a flat aligned with the set screw. Tightening against the round shaft can damage the shaft and make removal difficult.

- Handwheel use: The dual-shaft design lets you mount a handwheel on the rear shaft for manual operation when the drivers are powered down. When the motors are energized, they hold position and cannot be moved easily by hand.

- Controller compatibility: P/N 67127 with the 5-pin DIN plug is designed to plug directly into Sherline’s 4-axis driver box, CNC systems, and linear and rotary controllers. P/N 67130 (no plug) is intended for non-Sherline or custom controllers.

CNC Linear Controller with Stepper Motor

This stand-alone controller is fully programmable via its integrated keypad and directly controls the stepper motor to which it is connected. The stepper motor can be applied to any axis of a CNC-Ready Sherline machine.

An 8-pin mini-DIN cable allows multiple controllers to be connected in a “daisy-chain” configuration. Controllers can signal one another to operate in sequence, enabling complex, multi-axis movements without the need for a computer or master CNC controller. The system can also be used alongside existing CNC controllers. Each controller stores two independent programs, with up to 40 operations per program. For each operation, you can define travel distance, direction, feed rate, and whether the sequence pauses or proceeds to the next step.

The linear controller can also be daisy-chained with Sherline’s rotary controller, enabling coordinated rotary and linear motion. This allows users to easily perform advanced operations—such as gear cutting—without requiring CNC programming skills beyond simple keypad inputs.

Included with the CNC Linear Controller:

Note: To add CNC linear control to an axis on a Sherline machine that does not have a stepper motor mount, see P/N 8850.

Power Supply Compatibility:

The included power supply operates on 110–240 VAC and automatically adjusts for global use (220–240V). Earlier versions of this product shipped with a 110 VAC-only power supply.

Mill Collet Set

Sherline milling collets are specifically designed for use with the Morse #1 internal taper, which is standard on both the Sherline lathe and vertical mill. Due to the shallow angle of the Morse #1 taper, tightening the drawbolt results in significantly greater clamping force compared to WW collets. For this reason, we recommend using these milling collets to securely hold miniature end mills (with 3/16" or 1/4" shanks), #1 and smaller center drills, Dremel® bits (1/8" shank), and a variety of other small cutters.

Inch Mill Collet Set: 1/8", 3/16", 1/4"

Metric Mill Collet Set: 3 mm, 4 mm, 6 mm

Note: Tools held in these collets must have a shank diameter within .001" of the stated size. Because of the shallow taper, the collet will remain tight in the spindle even after loosening the drawbolt. To release it, back the drawbolt out a few turns and tap it lightly to free the collet.

⚠️ CAUTION: When tightening the collet drawbolt with a Tommy bar, be careful not to insert the bar too far into the spindle. Doing so can damage the collet’s taper area. The red arrow in the image below shows an example of this type of damage.

Stepper Motors

P/N 67127 – Standard Stepper Motor (with Plug)

The standard Sherline stepper motor (P/N 67127) comes pre-wired with six leads into a 5-pin DIN connector that plugs directly into Sherline’s CNC driver boxes and linear or rotary controllers. Simply plug each motor into the corresponding axis cable for a quick, clean setup. This motor is ideal for typical Sherline CNC applications where cutting loads are moderate, such as machining aluminum, brass, plastics, and light cuts in steel.P/N 67130 – Stepper Motor (Without Plug)

P/N 67130 is the same basic motor as P/N 67127 but supplied with six raw wire leads and no connector. It is intended for non-Sherline controllers or custom installations where a different pinout or connector is required.P/N 67126 – High-Torque Stepper Motor

Sherline’s high-torque stepper motor (P/N 67126) uses the same NEMA 23 frame size and 1/4" dual shaft as the standard motor, but delivers over 75% more holding torque. This added torque is especially useful on the Z-axis, where it can better handle the weight of the headstock and motor, and for heavier cuts or higher feed rates. Rated at 2 amps, the high-torque motor is fully compatible with all Sherline CNC machines, including complete CNC systems, the 4-axis driver box, CNC rotary tables, and Sherline linear and rotary controllers. No power supply upgrade is required. [/pane] [pane title="Specifications Comparison"]| Specification | P/N 67127 – Standard | P/N 67126 – High-Torque |

|---|---|---|

| Frame size | NEMA #23 | NEMA #23 |

| Shaft | 1/4" diameter, dual shafts | 1/4" diameter, dual shafts |

| Step angle | 1.8° (200 steps/rev) | 1.8° (200 steps/rev) |

| Holding torque | 0.775 N·m 7.9 kg-cm 109.71 oz-in 6.856 in-lb | 1.35 N·m 13.756 kg-cm 191.17 oz-in 11.948 in-lb |

| Maximum RPM | 530 RPM | 530 RPM |

| Voltage (nominal) | 3.2 V DC | 4.5 V DC |

| Current | 2.0 A/phase | 2.0 A/phase |

| Rotor inertia | 250 g-cm² | 480 g-cm² |

| Axial / radial load (max) | See spec sheet | Axial: 15 N (3.37 lbf) Radial: 75 N (16.86 lbf) |

| Number of leads | 6 leads (with DIN plug on 67127) | 6 leads |