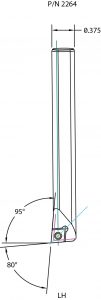

LH 55° & 80° 3/8″ Boring Bars w/Carbide Inserts

These 3/8″ diameter boring bars hold a carbide insert secured with a Torx screw. Each comes with either a 2-sided 55° or 80° carbide insert and Torx wrench. The 55° LH boring tool will fit into a 3/4″ starting hole. The 80° holder will fit into a smaller 1/2″ hole. The 80° holder offers a little more strength for roughing cuts while the 55° insert will cut into sharper corners. The 3-1/4″ long holder can bore a hole a little over 2″ deep with two fastening screws tightened on it. The holders are made from 1144 Stress-proof steel with a black oxide finish. Available individually.

Left Hand Boring Bars

These LH boring bars are not intended to be used for boring on a standard Sherline lathe, as the spindle is not reversible without electronic modifications. They were developed for a Sherline tool that is now in development where they will be used as a turning tool from the backside with the bit upside down. Watch for the introduction of this new “chucker” lathe soon.

Advantages of Using Carbide Insert Tools

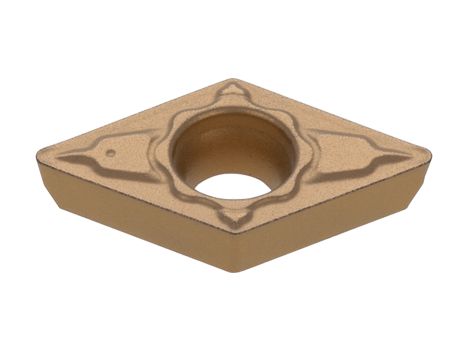

Though relatively expensive, if a cutting edge of a carbide insert becomes dull or chipped, the insert can be removed and rotated 180° to expose two new cutting surfaces, providing, in effect, two tools for the price of one.

The primary method of cutting metal on miniature machine tools is usually with high-speed steel tools as they are inexpensive, easily resharpened and can be ground into “form” tools for special jobs. However, inserted tip carbide tools can be lifesavers for some jobs. Though more expensive and not able to be resharpened, carbide tools hold their cutting edge when cutting exotic metals like stainless steel or titanium or abrasive materials like carbon fiber and can speed up the cutting process. This is why they are used for most cutting tasks in the modern professional machine shop.

NOTE: A tool is named by the direction from which the chip leaves the tool; so a right-hand tool has its cutting edge on the left and the chip peels off to the right.

-

| Insert Holder Material | 1144 Stressproof Steel |

|---|---|

| Body Coating | Black Oxide |

| Insert Material | Carbide |

Related products

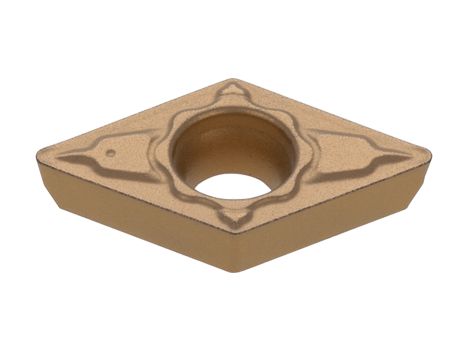

55° Carbide Insert

While not inexpensive, carbide inserts offer excellent value—each insert provides four cutting edges, significantly reducing the need for frequent sharpening and saving valuable time.

Carbide cutters perform well on hard-to-machine materials like cold-rolled steel and are also effective on aluminum, brass, and leaded steels, offering exceptional durability. However, for the finest finishes on softer metals, a well-sharpened high-speed steel tool still delivers superior results.

This is the 10-pack of replacement carbide inserts for the following tool holders:

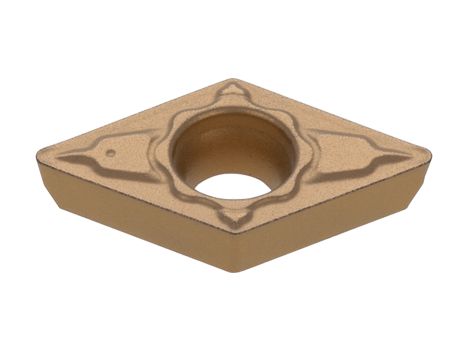

55° Carbide Insert-10 Pack

While not inexpensive, carbide inserts offer excellent value—each insert provides four cutting edges, significantly reducing the need for frequent sharpening and saving valuable time.

Carbide cutters perform well on hard-to-machine materials like cold-rolled steel and are also effective on aluminum, brass, and leaded steels, offering exceptional durability. However, for the finest finishes on softer metals, a well-sharpened high-speed steel tool still delivers superior results.

This is the 10-pack of replacement carbide inserts for the following tool holders:

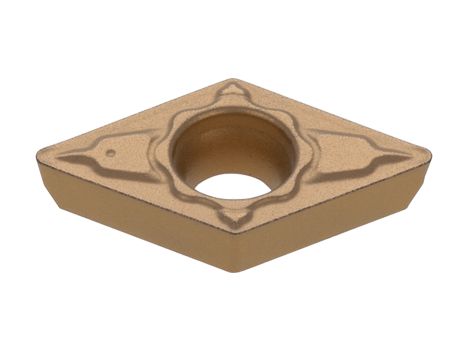

80° Carbide Insert

While carbide inserts may have a higher upfront cost, they offer excellent value by providing four usable cutting edges per insert and significantly reducing time spent on tool sharpening.

Carbide cutters excel at machining difficult materials such as cold-rolled steel, stainless steel, and bronze, delivering consistent performance and long tool life. They are also compatible with aluminum, brass, and leaded steels—though for these softer materials, a finely honed high-speed steel tool may still yield the best surface finish.

This is the 10-pack of replacement carbide inserts for the following tool holders:

80° Carbide Insert-10 Pack

While carbide inserts may have a higher upfront cost, they offer excellent value by providing four usable cutting edges per insert and significantly reducing time spent on tool sharpening.

Carbide cutters excel at machining difficult materials such as cold-rolled steel, stainless steel, and bronze, delivering consistent performance and long tool life. They are also compatible with aluminum, brass, and leaded steels—though for these softer materials, a finely honed high-speed steel tool may still yield the best surface finish.

This is the 10-pack of replacement carbide inserts for the following tool holders: