5C 4″ 4-Jaw Independent Chuck

5C collets are widely used in machine shops, but there are times when the exact size collet isn’t available, or when a part requires the flexibility of a 4-jaw chuck. This 4” 4-jaw chuck with a 5C back allows you to quickly switch between a collet and a chuck without disassembling your setup or moving to another machine. Simply remove the collet and insert the chuck into your existing 5C holder. When you’re finished, you can just as easily switch back to collets.

The 5C back features the standard taper, thread, and keyway, and is CNC-machined from a single billet of steel to ensure concentricity between the back and the chuck body. The compact 4” chuck comes with reversible jaws and a chuck key for easy adjustments.

Note: 5C collets are designed for use on full-size machines. This chuck is intended for use with such machines and is not compatible with Sherline lathes.

-

| Chuck Diameter | 3.1″ |

|---|---|

| Jaw Capacity | With jaws in normal position: 3/32″ (2mm) – 1-3/16″ (30mm)

With jaws in reverse position: 3/32″ (2mm) – 2-1/4″ (56mm) |

| Through Hole Diameter | .79″ (20mm) |

| Spindle Taper | 5C |

| Chuck Body Material | 12L14 Steel |

| Chuck Jaws Material | 12L14 Case Hardened Steel |

Because chuck jaws are factory ground to precisely match each chuck body all replacement orders must be made by phone.

Related products

- Turning and sizing ring blanks and bands

- Machining ring mandrels and expanding mandrels

- Cutting and finishing bezels, settings, and prongs

- Making collet-held parts and small precision components

- Truing and modifying stone setting tools

- Fabricating custom jigs, fixtures, and specialty tools

- Light turning of precious and non-precious metals

- Working with wax, plastic, aluminum, and steel for prototypes and tooling

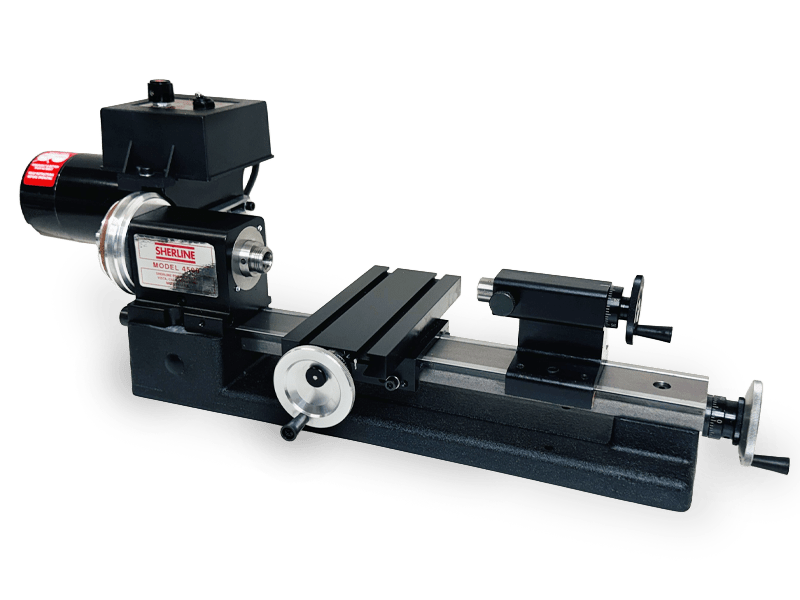

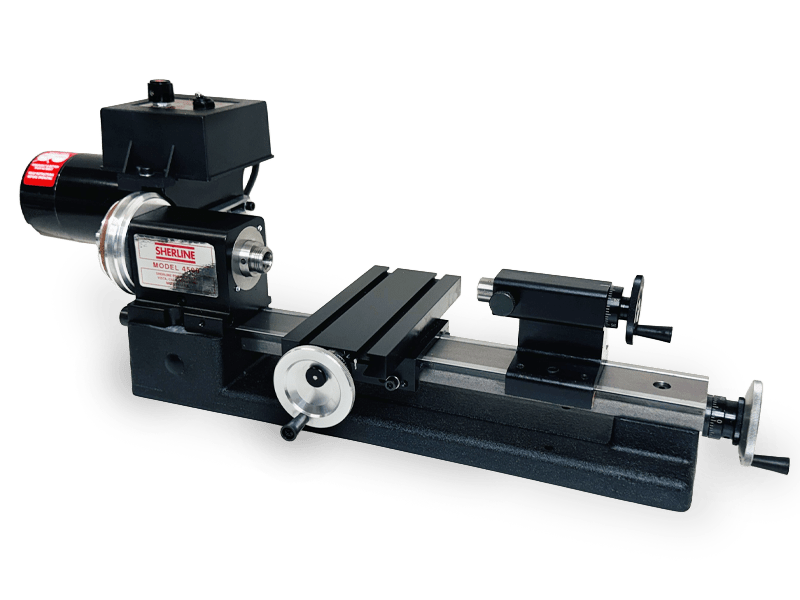

Sherline Precision Jewelers Lathe

Typical Jewelry & Gem-Cutting Applications

Expanding Ring Mandrel

Sherline Products, in collaboration with Bryan D. Drummond (gem cutter and goldsmith), designed this Expanding Ring Mandrel specifically for making and modifying rings on the Sherline lathe.

The mandrel is manufactured from 12L14 steel and features a black oxide finish for rust prevention.

It is designed for use with stepped ring collets manufactured by Ring Tech (Faceting Collets Stepped). These Ring Tech collets are known for their excellent quality and superior design, and, like our machines, are made in the USA. If you buy collets from Ringtech, tell them Sherline sent you.

If you are using a brand of collet that is shorter than the Ring Tech collets, the mandrel includes a spacer washer that fits against the shoulder of the mandrel. This allows shorter collets to be properly positioned at the front of the mandrel.