-

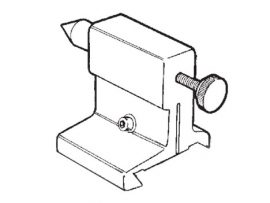

Linear Controller with Keypad

-

Power Supply

CNC Linear Controller with Power Supply

This stand-alone controller features an integrated keypad for easy programming and controls the operation of the connected stepper motor—no external computer or CNC system is required.

An 8-pin mini-DIN cable allows multiple controllers to be connected in a daisy-chain configuration. Each unit can send and receive signals to operate in sequence, enabling multi-axis motion without a master CNC controller. The controllers can also interface with existing CNC systems for more complex setups.

Each controller supports two independent programs, with up to 40 steps per program. Each step can define travel distance, direction, speed, and whether to pause or automatically continue to the next command.

The linear controller can also be daisy-chained with Sherline’s rotary controller, enabling combined linear and rotary motion. This simplifies more advanced tasks—such as gear cutting—without requiring any G-code knowledge beyond the simple keypad inputs.

Included with the Linear Controller:

Power Supply Specifications:

The included power supply is compatible with 110–240 VAC and automatically adjusts to local voltage, making it suitable for use worldwide. (Earlier versions of this product included a 110 VAC-only power supply.)