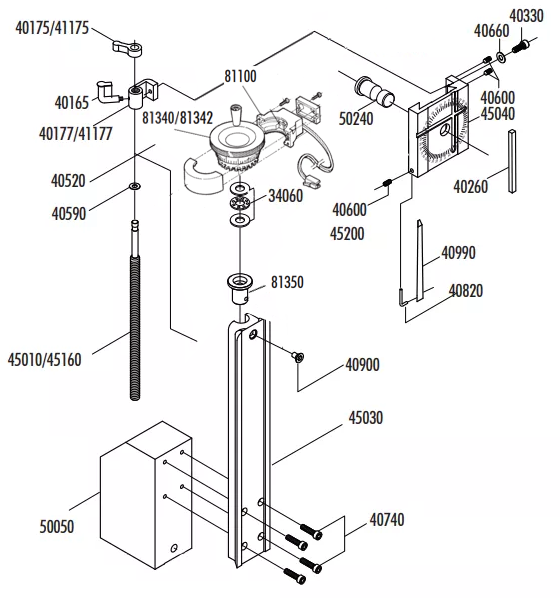

Mill Column – DRO

NOTE: This column is for a mill, if you want to put this column on a lathe click here

-

| Part No. | Description | Quantity |

|---|---|---|

| 34060 | Thrust Bearing Set | 1 |

| 40175 41175 |

Saddle Locking Lever (Inch) Saddle Locking Lever (Metric) |

1 |

| 40177OL 41177OL |

Saddle Nut with Oiler (Inch) Saddle Nut with Oiler (Metric) |

1 |

| 40260 | Head Key | 1 |

| 40330 | 10-32 x 5/8″ SHCS | 1 |

| 40590 | 1/4″ Washer | 1 |

| 40600 | 10-32 x 1/4″ Flat Point Set Screw | 3 |

| 40660 | #10 Washer 3/16″ | 1 |

| 40740 | 10-32 x 7/8″ SHCS | 4 |

| 40820 | Gib Lock | 1 |

| 40900 | 10-32 x 3/8″ Flat Head Screw | 1 |

| 40990 | Saddle Gib | 1 |

| 45010 45160 |

Column Lead Screw (Inch) Column Lead Screw (Metric) |

1 |

| 45030 | Column Bed | 1 |

| 45040 | Column Saddle | 1 |

| 50050 | Mill Column Base | 1 |

| 50220 | 1/4-20 x 1-3/4″ SHCS | 2 |

| 50240 | Pivot Pin | 1 |

| 76140 | 5/64″ Hex Key | 1 |

| 81100 | Encoder Unit with Cable | 1 |

| 81340 81342 |

2.5″ Z Axis DRO Handwheel (Inch) 2.5″ Z Axis DRO Handwheel (Metric) |

1 |

| 81350 | DRO Z Axis Thrust Collar | 1 |

Related products

3/8″ Double-Ended End Mill Sets

These precision 3/8″ shank double-ended end mill sets are a versatile and budget-friendly choice for general milling work. Double-ended cutters give you two cutting ends in one tool, doubling your productivity and value. Each cutter features a flat section on the shank for secure clamping in a 3/8″ end mill holder.

Both sets include six popular diameters: 1/8″, 5/32″, 3/16″, 1/4″, 5/16″ and 3/8″.

7400 – 2-Flute Set

Ideal for softer materials such as aluminum, these 2-flute cutters resist clogging and provide smooth chip evacuation.

7401 – 4-Flute Set

With four cutting edges, this set offers increased cutting contact and is better suited for harder materials like steel.

Each set includes a wooden storage block to protect your cutters when not in use

CAUTION: Unlike a drill bit that looks similar, end mills are sharpened on the edges as well as the tip. These sharp edges demand a lot of respect when being handled and used! Also, to keep them sharp, store them in the block provided or individually protected in your toolbox.

Mill Collet Set

Sherline milling collets are specifically designed for use with the Morse #1 internal taper, which is standard on both the Sherline lathe and vertical mill. Due to the shallow angle of the Morse #1 taper, tightening the drawbolt results in significantly greater clamping force compared to WW collets. For this reason, we recommend using these milling collets to securely hold miniature end mills (with 3/16" or 1/4" shanks), #1 and smaller center drills, Dremel® bits (1/8" shank), and a variety of other small cutters.

Inch Mill Collet Set: 1/8", 3/16", 1/4"

Metric Mill Collet Set: 3 mm, 4 mm, 6 mm

Note: Tools held in these collets must have a shank diameter within .001" of the stated size. Because of the shallow taper, the collet will remain tight in the spindle even after loosening the drawbolt. To release it, back the drawbolt out a few turns and tap it lightly to free the collet.

⚠️ CAUTION: When tightening the collet drawbolt with a Tommy bar, be careful not to insert the bar too far into the spindle. Doing so can damage the collet’s taper area. The red arrow in the image below shows an example of this type of damage.