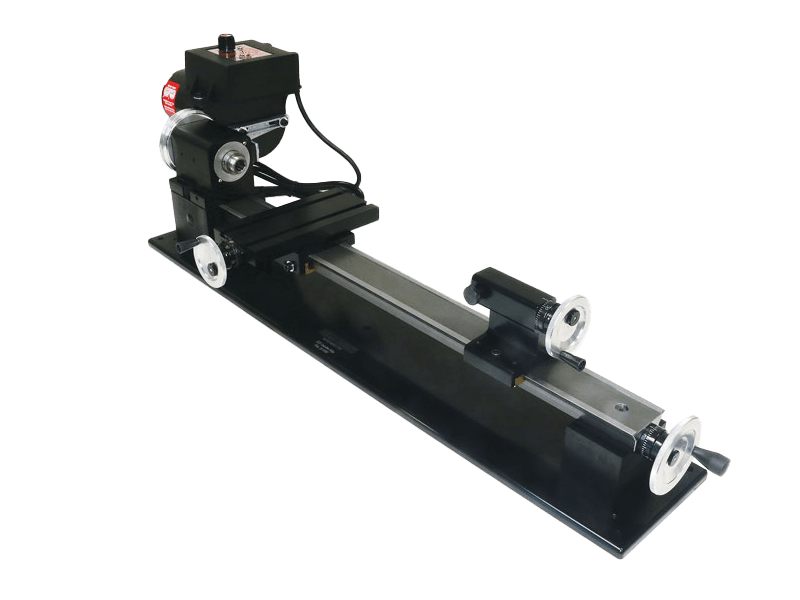

17″ Benchtop Lathe

Our benchtop lathe offers 17″ between centers, more than double the 8″ available on the tabletop model, giving you significantly more clearance. This extra space becomes especially useful when a part is held in a chuck and the tailstock also holds a larger drill chuck with a long bit, where a shorter bed might fall short.

With the additional 9″ of center-to-center distance, along with adjustable “zero” handwheels and a rocker-style tool post, this lathe brings more flexibility and capability – a worthwhile upgrade over the shorter version.

Although compact in size, our 17″ benchtop lathe still delivers the precision and accuracy expected from a full-size machine. It’s capable of turning wood and plastic, but is also rigid enough to handle aluminum and steel parts – making it suitable not just for hobby use, but for precision metalwork too.

Designed as a desktop-friendly machine, it packs full-size performance into a smaller footprint, offering a practical balance of convenience and capability for small shops or home workshops.

Features:

- Adjustable resettable “zero” handwheels: 2.5″ (63 mm) on the leadscrew, 2″ (51 mm) on both the crosslide feed screw and the tailstock – each handwheel has laser-engraved aluminum handwheel collars

- Turns parts up to 3.5″ (90 mm) diameter over the bed and 1.75″ (45 mm) over the carriage without riser blocks; with riser blocks, up to 6″ over the bed

- 17″ (430 mm) bed provides extended travel for longer workpieces

- 6″ (152 mm) crosslide for increased tool reach

- Precision-machined dovetail slides with adjustable gibs and backlash

- High-accuracy spindle and headstock used across all Sherline lathes

- Spindle speed: continuously variable from 70 to 2,800 RPM via electronic control (no belt changes required). A second pulley position offers more torque at low RPM if needed

- Rocker-style tool post (replacing the standard post used on shorter lathes)*

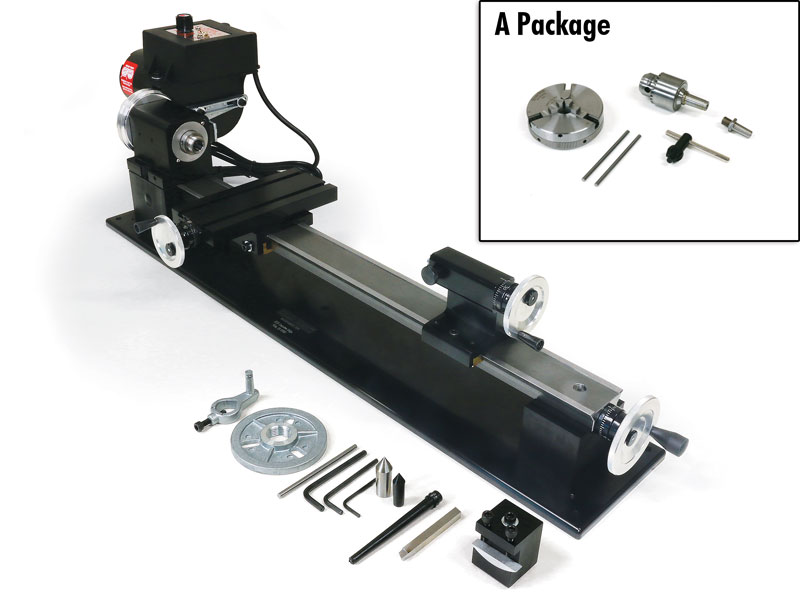

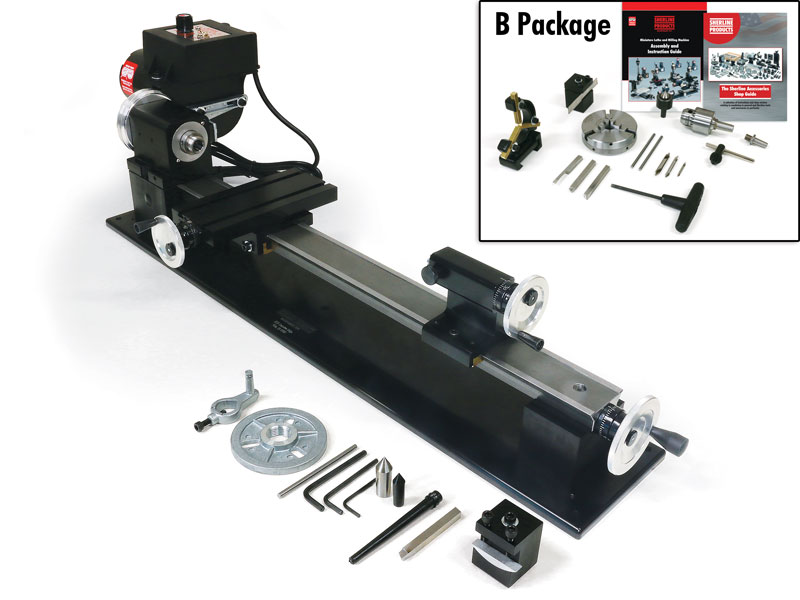

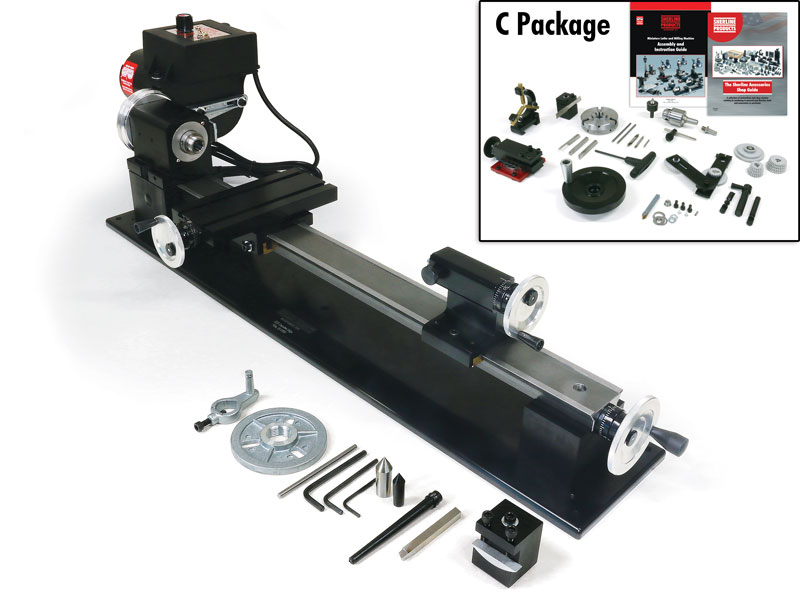

- Comes with pulleys, drive belt, faceplate, lathe dog, two dead centers, three hex keys, rocker tool post, a sharpened high-speed steel cutting tool, a grounded 3-wire power cord (8 ft), and instruction manual

- Compatible with Sherline’s full line of accessories

- Made in the USA

* Not included with lathe without motor and speed control

This 17″ benchtop lathe gives you the precision and robustness of a larger machine in a compact, desktop-sized package. The extended center distance, adjustable zero handwheels, rocker tool post, and variable-speed electronic motor make it a versatile choice for turning plastics, wood, aluminum, or steel. It’s ideal for small shops, hobbyists, or anyone needing a reliable lathe for detailed or small-batch work — with the convenience of a machine that doesn’t take up an entire shop floor.

-

| Swing Over Bed | 3.50″ (90 mm) |

|---|---|

| Swing Over Carriage | 1.75″ (45 mm) |

| Distance Between Centers | 17.00″ (430 mm) |

| Hole Through Spindle | .405″ (10 mm) |

| Spindle Nose Thread | 3/4″-16 T.P.I. |

| Spindle Nose Taper | #1 Morse |

| Spindle Runout of Morse Taper | .0005″ or less |

| Travel of Crosslide | 4.25″ (110 mm) |

| Tailstock Spindle Taper | #0 Morse |

| Protractor Graduations | 0° to 45° by 5° |

| Handwheel Graduations | .001″ (.01 mm) |

| Length Overall | 32.5″ (826 mm) |

| Width Overall | 8.00″ (267 mm) |

| Height Overall | 8.00″ (216 mm) |

| Shipping Weight | 31 lb. (14.1 kg) |

| Motor | 90 volt DC with electronic speed control that accepts any incoming current from 100VAC to 240 VAC, 50 Hz or 60 Hz.

Click here for motor specifications |

| Spindle Speed Range | 70-2800 RPM continuously variable by electronic speed control |

4400-Series Manual Benchtop Lathe-Machined Base

Click on the link for the exploded view of the 4400-Series Manual Benchtop Lathe (2024) to help identify replacement parts.

4400-Series Manual Benchtop Lathe-Cast Base

Click on the link for the exploded view of the 4400-Series Manual Benchtop Lathe to help identify replacement parts.

If you are still uncertain, please call our customer service representatives for help with this item.

Click the P/Ns below to download a zipped version of the IGS 3D CAD file. You will need to extract the zip file before viewing the files.

4400-Series 17″ Benchtop Lathe 3D IGS model

4400-Series 17″ Benchtop Lathe w/1041 3-Jaw Chuck 3D IGS model

You need an IGS viewer to open .igs files. CLICK HERE to download a FREE IGS viewer.

|

|

|

|---|---|---|

| 4000 (4100) | 4400 (4410) | |

| Swing over bed | 3.50″ (90 mm) | 3.50″ (90 mm) |

| Swing over carriage | 1.75″ (44.5 mm) | 1.75″ (44.5 mm) |

| Distance between centers | 8.00″ (200 mm) | 17.00″ (430 mm) |

| Hole through spindle | .405″ (10 mm) | .405″ (10 mm) |

| Spindle nose thread | 3/4-16 T.P.I. | 3/4-16 T.P.I. |

| Spindle nose taper | #1 Morse | #1 Morse |

| Spindle runout of Morse taper | 0005″ or less | .0005″ or less |

| Travel of crosslide | 4.25″ (110 mm) | 4.25″ (110 mm) |

| Tailstock spindle taper | #0 Morse | #0 Morse |

| Tailstock spindle travel | 1.75″ (44.5 mm) | 1.75″ (44.5 mm) |

| Protractor graduations | 0° to 45° by 5° | 0° to 45° by 5° |

| Handwheel graduations | 001″ (.01 mm) | 001″ (.01 mm) |

| Handwheel type | Standard Handwheels | Zero Adjustable Handwheels (With the exception of DRO machines, which come with DRO handwheels) |

| Electronically controlled spindle speed range | 70 to 2,800 RPM | 70 to 2,800 RPM |

| Length overall | 23″ (584 mm) | 32.5″ (826 mm) |

| Width overall | 10.25″ (260 mm) | 10.55″ (267 mm) |

| Height overall | 8″ (203 mm) | 8.5″ (216 mm) |

| Shipping weight | 24 lb. (10.9 kg) | 30 lb. (13.6 kg) |

| Motor Specs | ||

| Input voltage | 100 to 240 VAC, 50 or 60 Hz | |

| Output to motor | 90 VDC | |

| Current draw | .5 to 15 amps, depending on the load | |

| No-load output shaft speed | 6000 RPM (no pulley) | |

| Click here for more detailed specs | ||

| Spindle Specs | ||

| Spindle End play (factory adjustment of preload) |

.0002″ (.005 mm) or less, normal pulleys | |

| Runout at nose | .0005″ (0.013 mm) or less | |

| Bearings | Two 20 mm lifetime lubricated ball bearings with adjustable preload | |

Related products