Back to CNC Controllers

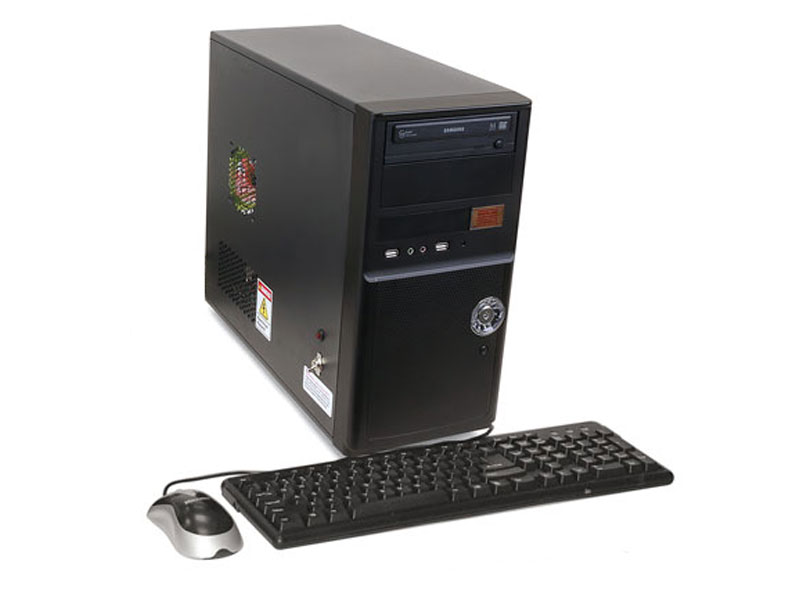

LinuxCNC Computer System with Driver Box

- Built-in Driver box (Converts g-code to steps to run DC stepper motors)

- Output cables for X, Y, Z, and A pre-wired with DIN plugs for stepper motors

- Keyboard and mouse (you supply the monitor)

- Processor Speed: 2 GHz or faster

- RAM: 2 GB

- Hard Drive: 500 GB

- Internal drive: DVD-RW

- External drive: 4 GB USB Flash drive for transferring g-code files

- Current: Internal switches are set to 110VAC but can be reset for operation with 230 VAC

- Installed software: Ubuntu 12.04 Linux-based OS with Linux CNC 2.6.11 4-axis CNC software.

- 90-day warranty on CNC and computer-related components.

Prior to January, 2005, Redhat version 2.xx was installed. From January, 2005 to September, 2009, Debian version 4.xx was installed. Starting in October, 2009 Ubuntu version was installed. Our 6.0 version of Ubuntu with “Lucid” build installed starting February, 2010. Debian wheezy 2017. Current software as of 2018 is Ubuntu 12.04 with Linux CNC 2.6.11

The most up-to-date version of the instructions can be found at CNC 7 Instructions. Instructions for Debian systems purchased between January 1, 2005, and September 17, 2009, can be found at CNC 4 Instructions. For those using a system purchased before January 1, 2005, instructions for the 2.xx Redhat version can be found on the Sherline CNC Instructions web page.

-

SKU: 8761

Categories: CNC Components, CNC Components, CNC Controllers, Driver Box, & Software, Replacement Parts

Tag: CNC

Related products

- NEMA 23 frame size – fits Sherline CNC-ready mills, lathes, and rotary tables.

- Dual-shaft design – both ends of the shaft are usable; flats are ground on each end for secure attachment of handwheels and couplings.

- Standard step angle – 1.8° per step (200 steps/rev) for precise motion control.

- 2.0 A/phase – both motors are rated at 2.0 amps and work with existing Sherline CNC power supplies and driver electronics.

- 6-lead wiring – allows use in a variety of bipolar or unipolar configurations (see spec sheets for wiring diagrams).

- Designed for Sherline CNC – plug-and-play with Sherline driver boxes and motion controllers when used with the supplied connectors.

- Coupler requirement: Because of the increased torque, the high-torque motor (P/N 67126) must be used with the updated CNC coupling (P/N 671052). This coupling replaces the older 3-slot coupling (P/N 67105).

- Motor mounts: When used with a Sherline stepper motor mount (P/N 67101), be sure that the shaft entering the coupling has a flat aligned with the set screw. Tightening against the round shaft can damage the shaft and make removal difficult.

- Handwheel use: The dual-shaft design lets you mount a handwheel on the rear shaft for manual operation when the drivers are powered down. When the motors are energized, they hold position and cannot be moved easily by hand.

- Controller compatibility: P/N 67127 with the 5-pin DIN plug is designed to plug directly into Sherline’s 4-axis driver box, CNC systems, and linear and rotary controllers. P/N 67130 (no plug) is intended for non-Sherline or custom controllers.

4-Axis CNC Driver Box

In designing our CNC systems, we fitted the driver board and power supply directly inside the PC. For users who’d prefer to build their own setup or use a different PC, we offer this complete driver box and power supply as a standalone solution.

Housed in an anodized aluminum enclosure, this unit includes four stepper-motor drivers — labeled X, Y, Z and A — each terminating in a dedicated cable that plugs directly into the corresponding pre-wired Sherline stepper motor. The kit also includes a 6′ (approx.) DB-25 parallel cable to connect the box to your computer’s parallel port, and an externally-mounted 24 VDC power supply (included) that simply plugs into the driver box.

CNC Rotary Table with Stepper Motor

A fully integrated 4″ (100 mm) precision rotary table with a built-in NEMA 23 stepper motor and plug-in interface, ready to serve as the A-axis on your Sherline CNC milling setup. Designed for seamless G-code control and radial machining, it supports continuous loads of 50 lbs horizontally, 30 lbs vertically, and delivers approx. 6 ft-lbs of vertical torque. Backlash is held under 0.2° and it achieves roughly 28,800 steps per revolution (~0.006°/step) for high-accuracy indexing.

Stepper Motors

Sherline stepper motors are NEMA 23, dual-shaft motors designed specifically for our CNC mills, lathes, and rotary tables.

Both the standard motor (P/N 67127) and the high-torque motor (P/N 67126) are rated at 2.0 A/phase and are fully compatible with Sherline CNC systems, driver boxes, and motion controllers. The dual-shaft design allows you to add handwheels for manual control when needed.

[accordion]

[pane title="Features"]

[/pane]

[pane title="Compatibility & Installation Notes"]

P/N 67127 – Standard Stepper Motor (with Plug)

The standard Sherline stepper motor (P/N 67127) comes pre-wired with six leads into a 5-pin DIN connector that plugs directly into Sherline’s CNC driver boxes and linear or rotary controllers. Simply plug each motor into the corresponding axis cable for a quick, clean setup. This motor is ideal for typical Sherline CNC applications where cutting loads are moderate, such as machining aluminum, brass, plastics, and light cuts in steel.P/N 67130 – Stepper Motor (Without Plug)

P/N 67130 is the same basic motor as P/N 67127 but supplied with six raw wire leads and no connector. It is intended for non-Sherline controllers or custom installations where a different pinout or connector is required.P/N 67126 – High-Torque Stepper Motor

Sherline’s high-torque stepper motor (P/N 67126) uses the same NEMA 23 frame size and 1/4" dual shaft as the standard motor, but delivers over 75% more holding torque. This added torque is especially useful on the Z-axis, where it can better handle the weight of the headstock and motor, and for heavier cuts or higher feed rates. Rated at 2 amps, the high-torque motor is fully compatible with all Sherline CNC machines, including complete CNC systems, the 4-axis driver box, CNC rotary tables, and Sherline linear and rotary controllers. No power supply upgrade is required. [/pane] [pane title="Specifications Comparison"]| Specification | P/N 67127 – Standard | P/N 67126 – High-Torque |

|---|---|---|

| Frame size | NEMA #23 | NEMA #23 |

| Shaft | 1/4" diameter, dual shafts | 1/4" diameter, dual shafts |

| Step angle | 1.8° (200 steps/rev) | 1.8° (200 steps/rev) |

| Holding torque | 0.775 N·m 7.9 kg-cm 109.71 oz-in 6.856 in-lb | 1.35 N·m 13.756 kg-cm 191.17 oz-in 11.948 in-lb |

| Maximum RPM | 530 RPM | 530 RPM |

| Voltage (nominal) | 3.2 V DC | 4.5 V DC |

| Current | 2.0 A/phase | 2.0 A/phase |

| Rotor inertia | 250 g-cm² | 480 g-cm² |

| Axial / radial load (max) | See spec sheet | Axial: 15 N (3.37 lbf) Radial: 75 N (16.86 lbf) |

| Number of leads | 6 leads (with DIN plug on 67127) | 6 leads |