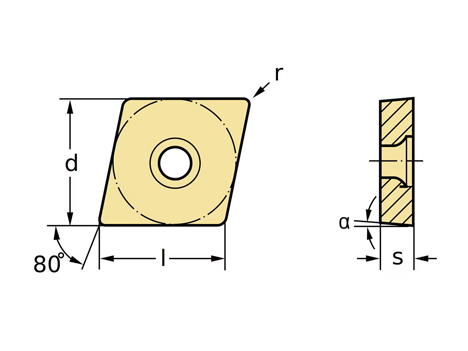

80° Carbide Insert-10 Pack

While carbide inserts may have a higher upfront cost, they offer excellent value by providing four usable cutting edges per insert and significantly reducing time spent on tool sharpening.

Carbide cutters excel at machining difficult materials such as cold-rolled steel, stainless steel, and bronze, delivering consistent performance and long tool life. They are also compatible with aluminum, brass, and leaded steels—though for these softer materials, a finely honed high-speed steel tool may still yield the best surface finish.

This is the 10-pack of replacement carbide inserts for the following tool holders:

- 80° Carbide Tool Holders

- 80° RH 3/8″ Boring Bar

- 80° LH 3/8″ Boring Bar

- 80° RH 3/8″ Boring Bar w/2 Flats

- 80° LH 3/8″ Boring Bar w/2 Flats

4 interest-free payments or as low as $10/mo with Affirm. Check your purchasing power

| INSCRIBED CIRCLE | 0.250″ (6.35 MM) |

| CUTTING EDGE LENGTH | 0.254″ (6.45 MM) |

| INSERT THICKNESS | 0.094″ (2.38 MM) |

| CLEARANCE ANGLE MAJOR | 11° |

| INCLUDED ANGLE | 80° |

| ISO INSERT DESIGNATION | CPMT 21.51 |

| CORNER RADIUS | 0.016″ (0.4 MM) |

| MINIMUM FEED PER REVOLUTION | 0.002″ (0.05 MM) |

| MAXIMUM FEED PER REVOLUTION | 0.006″ (0.16 MM) |

| DEPTH OF CUT MINIMUM | 0.004″ (0.1 MM) |

| MAX DEPTH OF CUT | 0.059″ (1.5 MM) |

Related products

Slitting Saws

Each saw blade is 2" in diameter with a 1/2" hole. The saw blades come in varying thicknesses and teeth counts. They require the slitting saw holder, which is held in the spindle with a drawbolt that pulls the holder up into the Morse #1 taper.

Note: Due to supply chain issues, the outside diameter of some of our saw blades may be 2-1/2" instead of 2" and teeth counts can vary. If you need a specific number of teeth in a certain size, please contact us to see if we have them in stock

Threading/Grooving Carbide Insert Tool Holder

Due to the variety of insert types and their cost, the holder is sold separately without inserts, allowing you to select only the specific inserts you need. The holder includes a clamp, 6-32 hold-down screw, and a 7/64" hex key for secure setup.

⚠️ CUSTOMER NOTICE — July 8, 2020

We’ve identified a potential issue affecting a small number of our Threading/Grooving Carbide Insert Tool Holders. Specifically, the cutting insert may not be securely clamped in place.

When tightening the clamp, the inside corner of the clamp may contact the step adjacent to the insert pocket, preventing full engagement with the clamping notch on the insert. This was caused by an early in-house clamp design that mistakenly used symmetrical angles on both sides of the clamp nose, rather than the intended asymmetrical design. This issue has since been corrected.

[caption id="attachment_33596" align="alignright" width="300"] Click on the image for a larger view.[/caption]

Click on the image for a larger view.[/caption]

To resolve the issue immediately:

-

Use a bench grinder or file to slightly grind down the back side of the clamp (see blue circle in the image).

-

This will allow the clamp tip to clear the step (indicated by the red arrow), ensuring full contact and proper clamping of the insert.

⚠️ CAUTION: Chips coming off the carbide inserts can be very HOT! Use extreme caution. Carbide inserts can also shatter. For these reasons, proper protective eyewear and clothing are especially important when using these tools. Materials like tool steel can form long, stringy chips that wrap around the part. Use a chip brush frequently, or pause machining to clear debris. Accumulated chips, especially when hot, can ignite. Keep the area around the cutter clean and free of chip buildup.