Back to Replacement Parts

Related products

- Turning and sizing ring blanks and bands

- Machining ring mandrels and expanding mandrels

- Cutting and finishing bezels, settings, and prongs

- Making collet-held parts and small precision components

- Truing and modifying stone setting tools

- Fabricating custom jigs, fixtures, and specialty tools

- Light turning of precious and non-precious metals

- Working with wax, plastic, aluminum, and steel for prototypes and tooling

Protected: Jeweler Point Carver System

Our Jeweler Point Carver System was developed in response to a request from Everett Walker Jewels. You can view Everett’s exceptional craftsmanship on Instagram at @everettwalkerjewels

Designed primarily for lapidary applications, this system provides jewelers with a precise and secure method for carving, shaping, and detailing stones and other small components.

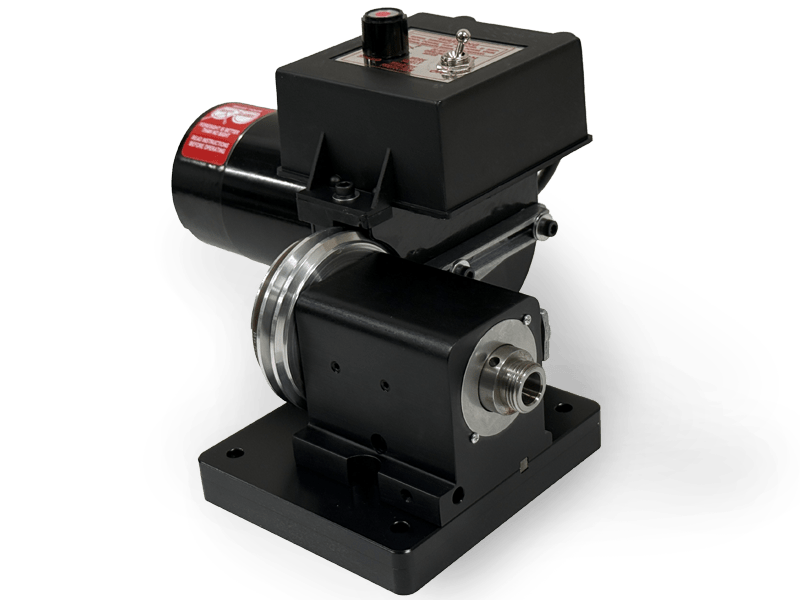

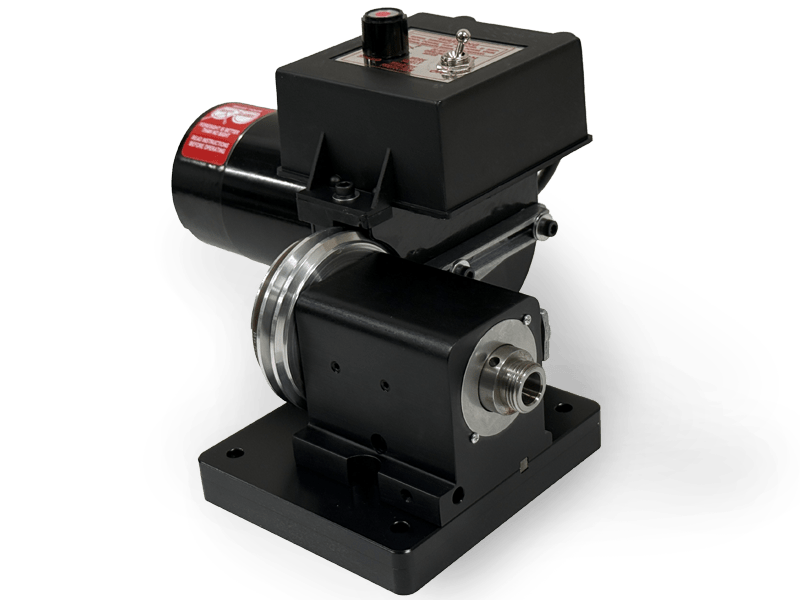

The system is built around our P/N 3306 headstock, which features a Morse #1 spindle taper. It can be purchased as a complete, standalone system or as an accessory for any Sherline lathe equipped with a Morse #1 headstock.

At the core of the system is the headstock, paired with a motor and electronic speed control to deliver smooth, variable-speed operation.

The system offers four interchangeable holder options. Each holder features a Morse #1 taper mount that fits directly into the headstock spindle. The taper mount provides a highly secure and concentric connection, making it one of the most reliable methods for mounting accessories on a rotating axis.

Each holder includes our P/N 30880 ¼-20 drawbolt and washer, ensuring the holder is securely retained within the spindle’s Morse #1 taper during operation.

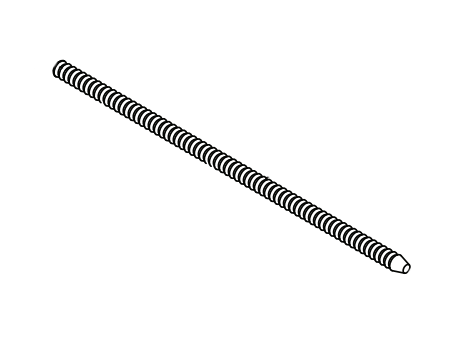

The Point Carver System also includes our P/N 1156 #1 Morse Taper Remover, allowing holders to be safely and easily released from the spindle taper when changing setups.

Sherline Precision Jewelers Lathe

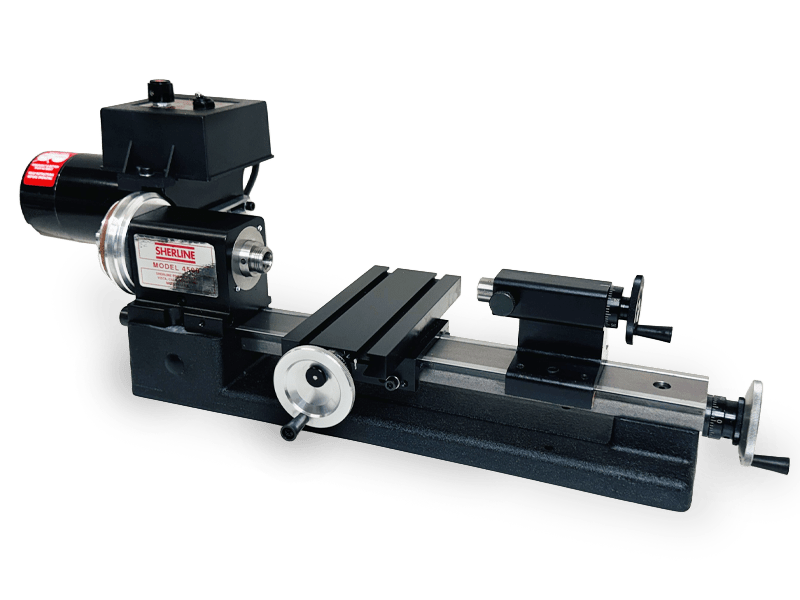

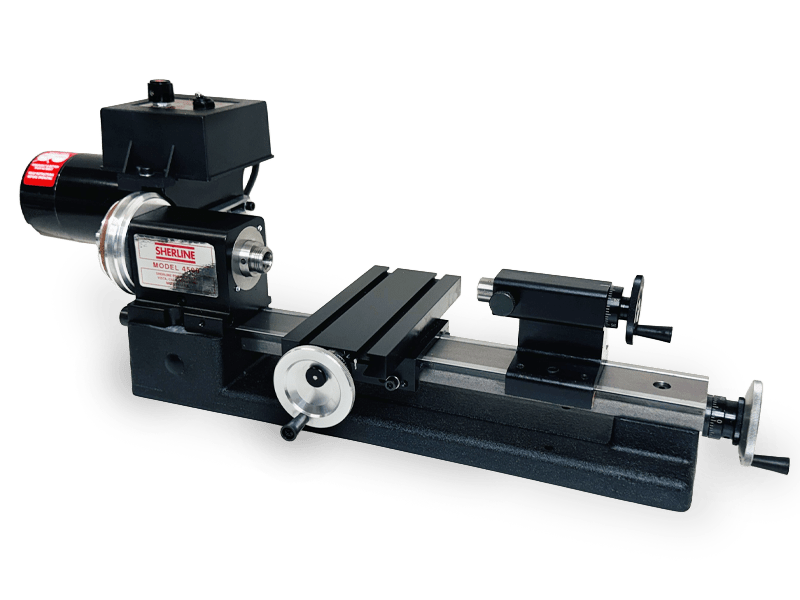

The 8″ tabletop lathe is an ideal precision tool for jewelers and gem cutters working on small, detailed components such as rings, settings, mandrels, bezels, bushings, and custom fixtures. It can turn parts up to 3.5″ in diameter over the bed or 1.88″ over the carriage, with 8″ of distance between centers, providing ample capacity for most jewelry and lapidary work without unnecessary machine size.

For jewelry applications, we often recommend the 8″ tabletop lathe over our 17″ model. The additional bed length of the 17″ lathe is rarely needed for typical jeweler or gem-cutting tasks, and its longer layout requires reaching farther to operate the Z-axis handwheel. The compact design of the 8″ lathe keeps both handwheels close to the work area, allowing for greater control, improved ergonomics, and more precise hand-fed cuts during fine finishing operations.

The lathe features an electronic speed control that provides continuously variable spindle speeds from 70 to 2,800 RPM without belt changes, making it easy to dial in the correct speed for delicate materials and small-diameter tools. A secondary pulley position is available when additional low-RPM torque is needed for tougher materials or heavier cuts. Despite its compact footprint, the machine is rigid and stable, delivering the smooth, controlled operation required for jewelry-scale precision.

Typical Jewelry & Gem-Cutting Applications

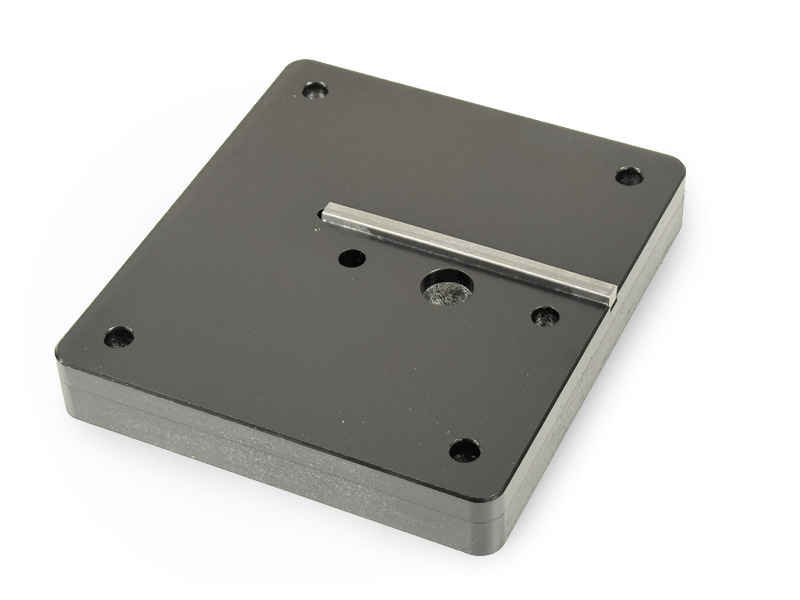

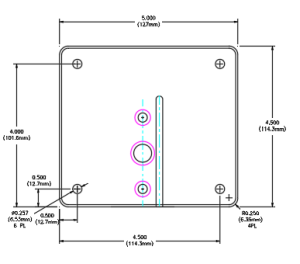

Expanding Ring Mandrel

Sherline Products, in collaboration with Bryan D. Drummond (gem cutter and goldsmith), designed this Expanding Ring Mandrel specifically for making and modifying rings on the Sherline lathe.

The mandrel is manufactured from 12L14 steel and features a black oxide finish for rust prevention.

It is designed for use with stepped ring collets manufactured by Ring Tech (Faceting Collets Stepped). These Ring Tech collets are known for their excellent quality and superior design, and, like our machines, are made in the USA. If you buy collets from Ringtech, tell them Sherline sent you.

If you are using a brand of collet that is shorter than the Ring Tech collets, the mandrel includes a spacer washer that fits against the shoulder of the mandrel. This allows shorter collets to be properly positioned at the front of the mandrel.