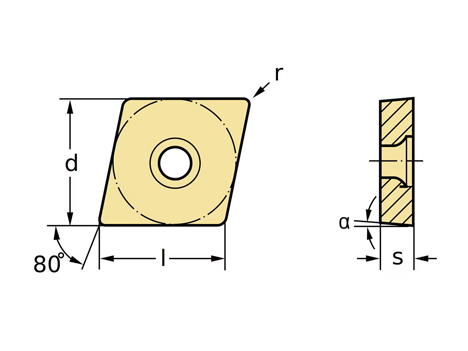

80° Carbide Insert

While carbide inserts may have a higher upfront cost, they offer excellent value by providing four usable cutting edges per insert and significantly reducing time spent on tool sharpening.

Carbide cutters excel at machining difficult materials such as cold-rolled steel, stainless steel, and bronze, delivering consistent performance and long tool life. They are also compatible with aluminum, brass, and leaded steels—though for these softer materials, a finely honed high-speed steel tool may still yield the best surface finish.

This is the 10-pack of replacement carbide inserts for the following tool holders:

- 80° Carbide Tool Holders

- 80° RH 3/8″ Boring Bar

- 80° LH 3/8″ Boring Bar

- 80° RH 3/8″ Boring Bar w/2 Flats

- 80° LH 3/8″ Boring Bar w/2 Flats

-

| INSCRIBED CIRCLE | 0.250″ (6.35 MM) |

| CUTTING EDGE LENGTH | 0.254″ (6.45 MM) |

| INSERT THICKNESS | 0.094″ (2.38 MM) |

| CLEARANCE ANGLE MAJOR | 11° |

| INCLUDED ANGLE | 80° |

| ISO INSERT DESIGNATION | CPMT 21.51 |

| CORNER RADIUS | 0.016″ (0.4 MM) |

| MINIMUM FEED PER REVOLUTION | 0.002″ (0.05 MM) |

| MAXIMUM FEED PER REVOLUTION | 0.006″ (0.16 MM) |

| DEPTH OF CUT MINIMUM | 0.004″ (0.1 MM) |

| MAX DEPTH OF CUT | 0.059″ (1.5 MM) |

Related products

Ceramic Insert Tool Holder

Designed for cutting hard materials like tool steel, this ceramic insert tool holder features a triangular insert mounted at a negative rake angle. The downward tilt of the insert provides proper side clearance, allowing you to use all six cutting edges—three per side—before needing a replacement. The 3/8" shank fits Sherline’s P/N 7600 tool post (not included). A clamp, hold-down screw, and 3/32" hex key are included for secure installation. Replacement inserts are available as (P/N 22659).

Why Use Ceramic Inserts?

Ceramic cutting tools are a powerful addition to the modern machinist’s toolbox. Though more brittle than high-speed steel (HSS) or carbide, ceramic inserts excel at cutting hardened steels and other tough materials, especially at higher spindle speeds. This makes them ideal for jobs that would otherwise be extremely difficult or impossible—such as turning down the shank of an end mill.

This insert’s large nose radius helps achieve an excellent surface finish, particularly when profiling.

-

Each insert offers six usable cutting edges:

-

Rotate 120° to access a new edge (3 per side), then

-

Flip the insert for 3 more cutting points on the opposite face

-

-

In comparison, traditional carbide inserts offer only 2–4 cutting edges, making ceramic inserts cost-effective over time, despite the higher upfront cost.

Usage Notes & Safety Information

-

Ceramic inserts are brittle and should be used with proper technique to avoid chipping or breakage.

-

Caution: Chips produced during cutting can be extremely hot—even red-hot. Use protective eyewear, gloves, and fire-safe clothing when operating.

-

Some materials, such as tool steel, may form long, stringy chips that wrap around the part ("bird’s nest" effect).

Use a chip brush and stop the machine frequently to clear chips. These chip clusters can ignite if they come in contact with hot chips.

RH 55° and 80° 3/8″ Boring Bars w/Carbide Inserts

These 3/8" diameter boring bars feature a carbide insert secured with a Torx® screw and come complete with a Torx wrench. Choose between:

-

A 55° right-hand insert, suitable for starting holes as small as 3/4", ideal for reaching sharp internal corners

-

An 80° insert, which fits into a smaller 1/2" hole and offers added strength for roughing operations

Each holder measures 3-1/4" long and can bore to a depth of just over 2" when properly secured with two set screws. Manufactured from durable 1144 Stressproof® steel with a black oxide finish, these tools are available individually or as a discounted set.

Why Choose Carbide Insert Tools?

While high-speed steel (HSS) remains common for small machine tools due to its low cost and resharpenability, carbide inserts offer significant advantages in demanding applications:

-

Longer-lasting edges when cutting hard metals like stainless steel, titanium, or abrasive materials such as carbon fiber

-

Faster cutting speeds and greater efficiency

-

Each insert can be rotated 180°, effectively giving you two cutting edges per insert

Although carbide inserts can't be resharpened, their durability and versatility make them a preferred choice in professional machine shops.

Note: The older straight-groove chip breaker insert is no longer available. Current inserts include the spider web-style chip breaker, as shown in the updated images here & here