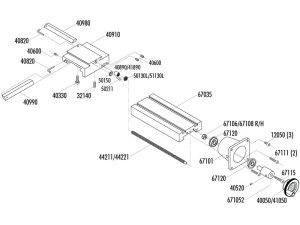

6″ Lathe Crosslide and Saddle Assembly – CNC Ready

-

| Part No. | Description | Quantity |

|---|---|---|

| 12050 | 8-32 x 3/8″ SHCS | 3 |

| 32140 | 10-32 x 1/2″ Cup Point Set Screw | 1 |

| 40050 41050 |

Y-Axis Handwheel (Inch) Y-Axis Handwheel (Metric) |

1 |

| 40330 | 10-32 x 5/8″ SHCS | 1 |

| 40520 | 10-32 x 3/16″ Cup PT Set Screw | 1 |

| 40600 | 10-32 x 1/4″ Flat Point Set Screw | 3 |

| 40890 41890 |

Slide Screw Insert (Inch) Slide Screw Insert (Metric) |

1 |

| 40820 | Gib Lock | 2 |

| 40910 | Lathe Saddle | 1 |

| 40980 | Crosslide Gib | 1 |

| 40990 | Saddle Gib | 1 |

| 44211 44221 |

6.5″ Slide Screw (Inch) 6.5″ Slide Screw (Metric) |

1 |

| 50130L 51130L |

Lathe Anti Backlash Nut (Inch) Lathe Anti Backlash Nut (Metric) |

1 |

| 50150 | Anti-Backlash Lock | 1 |

| 50211 | 8-32 x 1/4″ Button Socket Screw | 1 |

| 67101 | Stepper Motor Mount | 1 |

| 67035 | 6″ Crosslide | 1 |

| 671052 | CNC Coupling | 1 |

| 67106 67108 |

RH Coupling Preload Nut (course) (Inch) RH Coupling Preload Nut (course) (Metric) |

1 |

| 67111 | 8-32 x 7/8″ SHCS | 2 |

| 67115 | 5-40 x 7/8″ SHCS | 1 |

| 67120 | Stepper Motor Preload Bearing | 2 |

Related products

- Turning and sizing ring blanks and bands

- Machining ring mandrels and expanding mandrels

- Cutting and finishing bezels, settings, and prongs

- Making collet-held parts and small precision components

- Truing and modifying stone setting tools

- Fabricating custom jigs, fixtures, and specialty tools

- Light turning of precious and non-precious metals

- Working with wax, plastic, aluminum, and steel for prototypes and tooling

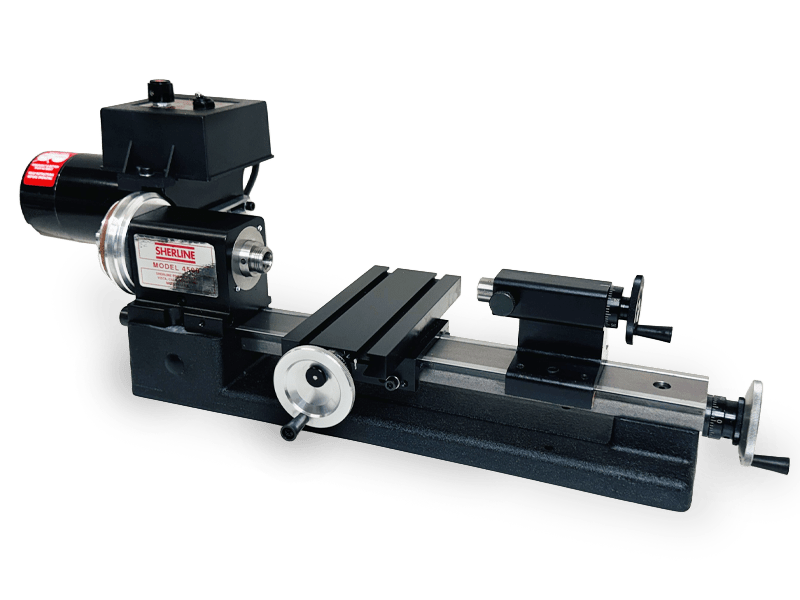

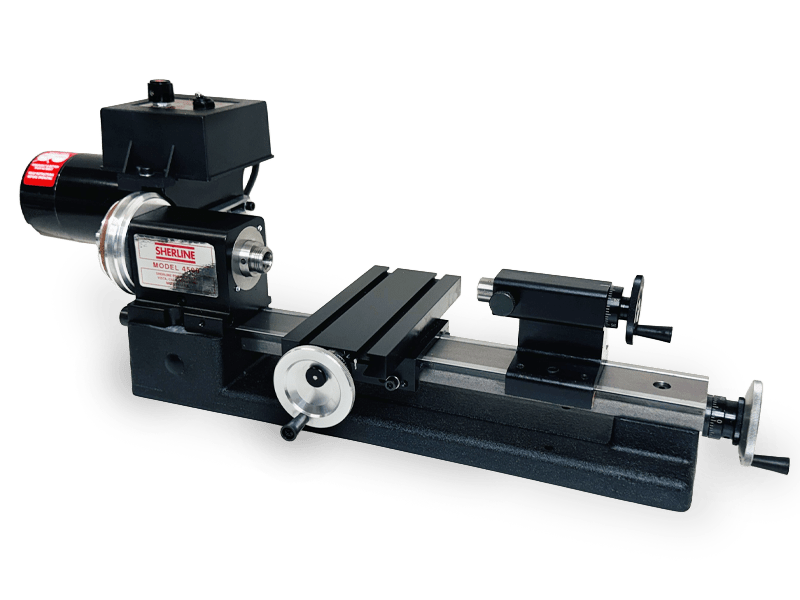

Sherline Precision Jewelers Lathe

Typical Jewelry & Gem-Cutting Applications

Expanding Ring Mandrel

Sherline Products, in collaboration with Bryan D. Drummond (gem cutter and goldsmith), designed this Expanding Ring Mandrel specifically for making and modifying rings on the Sherline lathe.

The mandrel is manufactured from 12L14 steel and features a black oxide finish for rust prevention.

It is designed for use with stepped ring collets manufactured by Ring Tech (Faceting Collets Stepped). These Ring Tech collets are known for their excellent quality and superior design, and, like our machines, are made in the USA. If you buy collets from Ringtech, tell them Sherline sent you.

If you are using a brand of collet that is shorter than the Ring Tech collets, the mandrel includes a spacer washer that fits against the shoulder of the mandrel. This allows shorter collets to be properly positioned at the front of the mandrel.