Product Description

Our CNC-ready benchtop lathe is perfect for the customer looking for a mini CNC lathe to make small, precision parts. All our lathes are made in the USA, and our customer service is second to none. Although our machines are small, they can produce high-quality precision parts. Our CNC lathe will cut wood and plastic and is rigid and accurate enough to cut aluminum and steel parts. This lathe is a desktop-size machine with full-size machine precision and accuracy.

Sherline CNC-ready lathes have factory-installed stepper motor mounts in place of the handwheels and are ready to apply 23-frame size stepper motors and computer numeric controls (CNC). CNC-Ready lathes are not turn-key machines and cannot be used until stepper motors have been installed. All lathes described as “CNC-ready” have stepper motor mounts but do NOT include stepper motors, computer, or CNC software.

Sherline recommends using dual-shaft stepper motors to apply handwheels to the rear shaft for manual control. With that in mind, handwheels for each axis are included with the machine, although you can’t use them until you install stepper motors. Sherline offers high-quality stepper motors and CNC options.

You can also find several aftermarket suppliers for motors, drivers, and software to complete the CNC system. You supply the 486 processor or, better, computer. See our CNC Dealers page for a list of suppliers and links to their home pages.

- A powerful 90V DC motor with electronic speed controller*

- 2.75″ (70mm) x 6.0″ (152mm) crosslide

- 24″ (610mm) steel bed that has 17″ (431mm) between centers

- 2.5″ (63mm) resettable, zero adjustable handwheel for the leadscrew, one 2″ (51mm) resettable, zero adjustable handwheels for the crosslide feed screw, and a 2″ (51mm) resettable, zero adjustable handwheel on the tailstock. Each handwheel has laser-engraved aluminum handwheel collars**

- Rocker tool post substituted for the standard tool post used on the short bed lathes

- Pulleys, drive belt, faceplate, lathe dog, two dead centers, three hexagonal keys, tool post, sharpened high-speed steel cutting tool, eight-foot three-wire power cord, and instruction manual

* Not included with lathe without motor and speed control

**CNC-ready machines cannot be operated manually unless double-shaft stepper motors are installed.

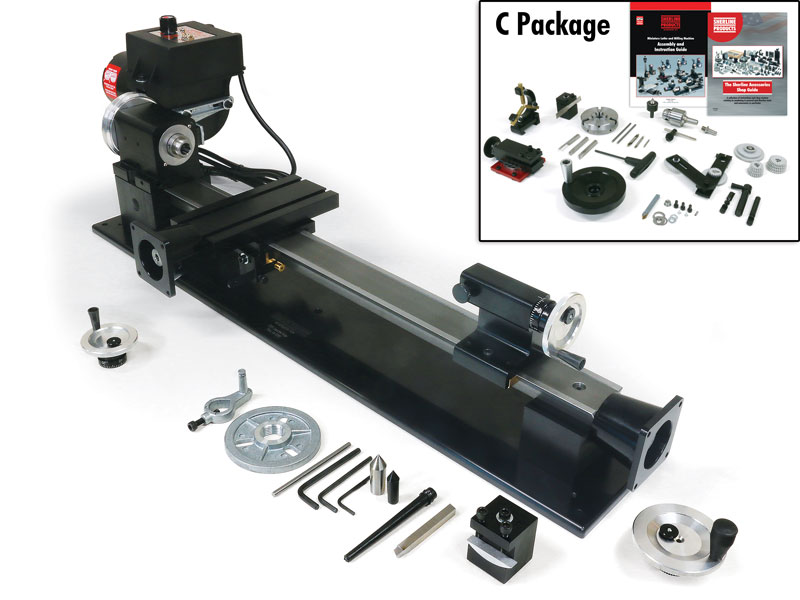

The C Package includes:

- 3.1″ 3-jaw self-centering chuck

- 3/8″ tailstock drill chuck w/ key, #0 Morse arbor, #1 Morse arbor with drawbolt

- Steady rest

- Live Center

- Compound Slide

- Rear Mount Cutoff Tool and Holder

- 3-pc 1/4″ HSS Cutting Tool Set (LH, RH, Boring)

- 5/32″ T-driver

- 3-pc Center Drill Set

- Sherline Accessories Shop Guide Book

- Thread Cutting Attachment

Other ordering options:

Similar to the XYZ bases for our mills, you can now order the lathe without the headstock, motor, or speed control. Please see the selections in the drop-down menu above.