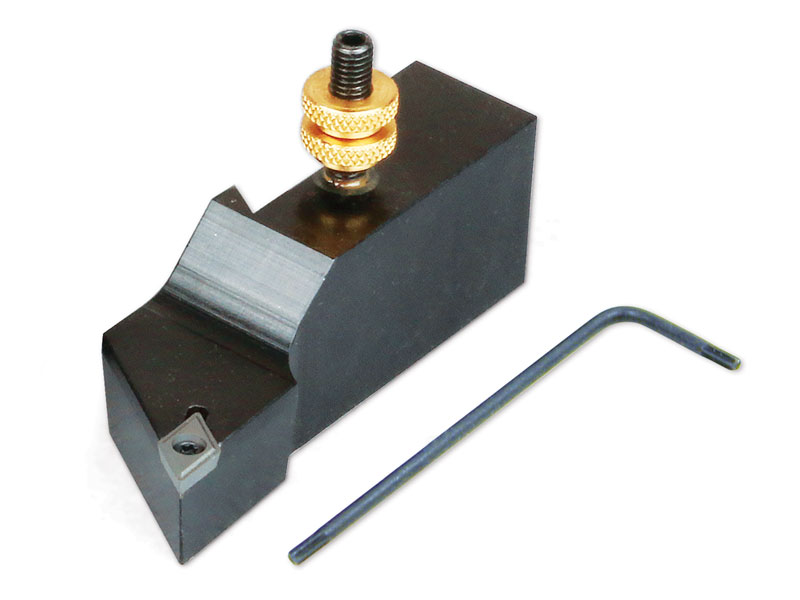

Quick-Change Carbide Insert Tool Holder

This holder is not included with the Quick-Change Tool Post System (P/N 2250) but is available separately for users who want to take advantage of the enhanced cutting performance offered by carbide tools. The holder includes one 55° carbide insert with two cutting edges, secured by a small screw. A Torx wrench for tightening the screw is also provided.

Like the Quick-Change Tool Post and other dovetailed holders in the system, this inserted tip holder is made from case-hardened steel with a black oxide finish for durability and corrosion resistance.

To learn more about the benefits of using inserted tip carbide tools, CLICK HERE to download a detailed PDF guide.

-

| Tool Post and Holders Body Material | Steel |

|---|---|

| Body Coating | Black Oxide |

2295 |

|

|---|---|

| 22550 | QC Carbide Insert-Holder Body |

| 22560 | 10-32 x 1″ Cup Point Set Screw |

| 22680 | QC Height Adjuster |

| 22580 | Torx T7 Wrench |

| 32100 | 10-32 Hex Nut |

| 7605 | 55-Degree Carbide Insert |

| 76232 | Torque Screw (Pt 542T) |

Related products

80° Carbide Insert-10 Pack

While carbide inserts may have a higher upfront cost, they offer excellent value by providing four usable cutting edges per insert and significantly reducing time spent on tool sharpening.

Carbide cutters excel at machining difficult materials such as cold-rolled steel, stainless steel, and bronze, delivering consistent performance and long tool life. They are also compatible with aluminum, brass, and leaded steels—though for these softer materials, a finely honed high-speed steel tool may still yield the best surface finish.

This is the 10-pack of replacement carbide inserts for the following tool holders:

Carbide Insert RH 55° 3/8″ Boring Bar w/2 Flats

Sherline’s gang-tooling tool post (P/N 5930) was specifically designed for customers converting their Sherline lathe into a chucker-style or gang-tooling lathe. Since most parts produced on a chucker lathe are 1/2" (13 mm) in diameter or smaller, and the center-to-center spacing on our gang-tooling post is 1.5" (38 mm), we identified a practical opportunity: our boring bars can double as both boring and outside diameter (O.D.) turning tools.

To support this dual use, we modified our standard boring bars by adding a second locating flat. This allows them to be mounted with the insert face up or face down, providing flexibility for front- or back-side operations. For example, right-hand 80° and 55° boring bars can now be used effectively on either side of the part (see Figure 1).

These 3/8" diameter boring bars are designed to hold a 2-sided 55° carbide insert, secured with a Torx® screw. Each holder includes an 55° carbide insert and a Torx driver.

-

Each holder is 3-1/4" long and can bore to a depth of just over 2" when secured with two set screws.

-

Constructed from 1144 Stressproof® steel with a black oxide finish for strength and corrosion resistance.

See instructions below for additional guidance on using two-flat boring bars with gang tooling setups.

Pro Tip: Consider using the boring bar with the insert face down to help reduce chip buildup on the insert during cutting. This orientation can improve chip evacuation and extend insert life.

FIGURE 1—55° boring bars used as examples. The left-hand tools are used as turning tools, while the right-hand tools are used as boring tools.

Note: The straight-groove chip breaker shown in some older images is no longer available. Current inserts feature the spider web-style chip breaker as shown here

Carbide Insert RH 80° 3/8″ Boring Bar w/2 Flats

Sherline’s gang-tooling tool post (P/N 5930) was specifically designed for customers converting their Sherline lathe into a chucker-style or gang-tooling lathe. Since most parts produced on a chucker lathe are 1/2" (13 mm) in diameter or smaller, and the center-to-center spacing on our gang-tooling post is 1.5" (38 mm), we identified a practical opportunity: our boring bars can double as both boring and outside diameter (O.D.) turning tools.

To support this dual use, we modified our standard boring bars by adding a second locating flat. This allows them to be mounted with the insert face up or face down, providing flexibility for front- or back-side operations. For example, right-hand 80° and 55° boring bars can now be used effectively on either side of the part (see Figure 1).

These 3/8" diameter boring bars are designed to hold a 2-sided 80° carbide insert, secured with a Torx® screw. Each holder includes an 80° carbide insert and a Torx driver.

-

Each holder is 3-1/4" long and can bore to a depth of just over 2" when secured with two set screws.

-

Constructed from 1144 Stressproof® steel with a black oxide finish for strength and corrosion resistance.

See instructions below for additional guidance on using two-flat boring bars with gang tooling setups.

Pro Tip: Consider using the boring bar with the insert face down to help reduce chip buildup on the insert during cutting. This orientation can improve chip evacuation and extend insert life.

FIGURE 1—55° boring bars used as examples. The left-hand tools are used as turning tools, while the right-hand tools are used as boring tools.

Note: The straight-groove chip breaker shown in some older images is no longer available. Current inserts feature the spider web-style chip breaker as shown here