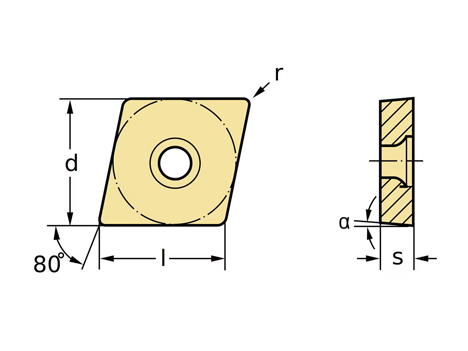

80° Carbide Insert

While carbide inserts may have a higher upfront cost, they offer excellent value by providing four usable cutting edges per insert and significantly reducing time spent on tool sharpening.

Carbide cutters excel at machining difficult materials such as cold-rolled steel, stainless steel, and bronze, delivering consistent performance and long tool life. They are also compatible with aluminum, brass, and leaded steels—though for these softer materials, a finely honed high-speed steel tool may still yield the best surface finish.

This is the 10-pack of replacement carbide inserts for the following tool holders:

- 80° Carbide Tool Holders

- 80° RH 3/8″ Boring Bar

- 80° LH 3/8″ Boring Bar

- 80° RH 3/8″ Boring Bar w/2 Flats

- 80° LH 3/8″ Boring Bar w/2 Flats

-

| INSCRIBED CIRCLE | 0.250″ (6.35 MM) |

| CUTTING EDGE LENGTH | 0.254″ (6.45 MM) |

| INSERT THICKNESS | 0.094″ (2.38 MM) |

| CLEARANCE ANGLE MAJOR | 11° |

| INCLUDED ANGLE | 80° |

| ISO INSERT DESIGNATION | CPMT 21.51 |

| CORNER RADIUS | 0.016″ (0.4 MM) |

| MINIMUM FEED PER REVOLUTION | 0.002″ (0.05 MM) |

| MAXIMUM FEED PER REVOLUTION | 0.006″ (0.16 MM) |

| DEPTH OF CUT MINIMUM | 0.004″ (0.1 MM) |

| MAX DEPTH OF CUT | 0.059″ (1.5 MM) |

Related products

Slitting Saws

Each saw blade is 2" in diameter with a 1/2" hole. The saw blades come in varying thicknesses and teeth counts. They require the slitting saw holder, which is held in the spindle with a drawbolt that pulls the holder up into the Morse #1 taper.

Note: Due to supply chain issues, the outside diameter of some of our saw blades may be 2-1/2" instead of 2" and teeth counts can vary. If you need a specific number of teeth in a certain size, please contact us to see if we have them in stock

1/4″ HSS Tool Blank Set

Lathe tools—also known as tool bits—are the cutting tools used for turning, facing, and other operations on a lathe. The most commonly used are high-speed steel (HSS) tools, which are suitable for machining a wide range of materials including wood, plastic, aluminum, brass, and steel. HSS tools maintain their hardness at temperatures up to 1000°F (588°C), making proper depth of cut, cutting speed, and feed rate essential for optimal performance.

One of the key advantages of HSS tools is how easily they can be resharpened using a standard aluminum oxide grinding wheel. Once sharpened, they retain a keen cutting edge through extended use.

Each Sherline lathe comes with a pre-sharpened 1/4" HSS cutting tool. Pre-ground tool sets—featuring right-hand, left-hand, and boring tools—are also available. However, for long-term savings and flexibility, learning to grind your own tools from blanks is recommended. Custom-shaped tools can be saved for repeat jobs or re-ground for new applications.