Product Description

Upgraded DRO Chip

Beginning August 1st, 2021, all DROs will ship with an upgraded chip. This new chip upgrade allows our Digital Readout to function with our ball screw machines as well as our standard leadscrew machines. We also programmed some upgrades based on customer feedback, like using Metric on Inch machines and using Inch on Metric machines.

The new DRO chip has six different modes to choose from based on the machine type, e.g., mill, lathe, leadscrew, or ball screw, and your preference of either inch or metric display on the DRO.

For more detailed information on setting up the modes for DRO, please see the DRO Mode Instructions.

NOTE: You must make sure you have the correct RPM tach sticker for your machine. Use a 6-pulse (P/N 81510) tach sticker if your machine is a leadscrew machine or a 5-pulse tach sticker (P/N P/N 87860) if your machine is a ball screw machine.

About the Sherline DRO Tabletop Lathe

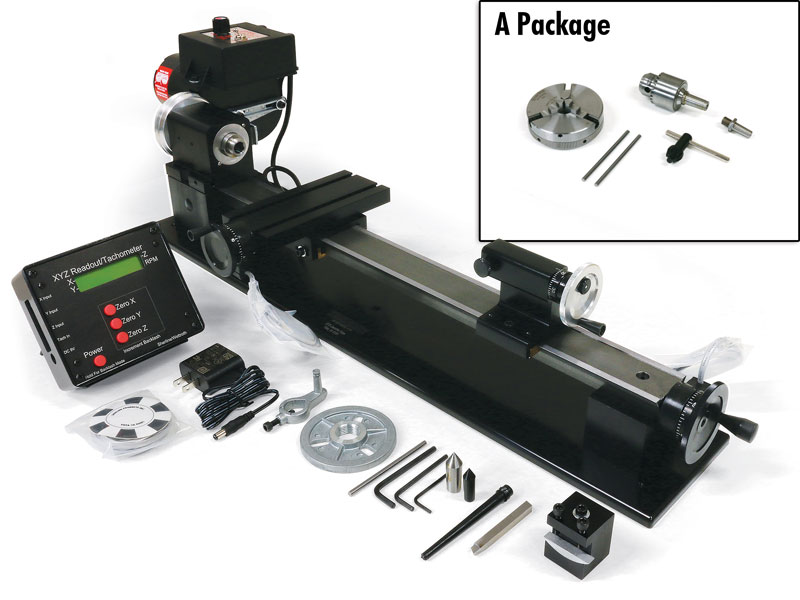

Our DRO tabletop lathe ships with a digital readout box and special handwheels with built-in electronic encoders that replace the standard handwheels. (The standard handwheels are not included when ordering the DRO option.) These special DRO handwheels are connected to the electronic readout box that translates the handwheel movement into a display of table travel for each of the three axes of movement. The readout for any axis can be reset to zero at any time with the push of a button. Spindle RPM is also constantly displayed on the DRO box whenever the motor is running. The readout can be fitted to either inch or metric machines.

Our DRO tabletop lathe is perfect for the customer looking for a mini DRO lathe to make small, precision parts. All our lathes are made in the USA, and our customer service is second to none. Although our machines are small, they can produce high-quality precision parts. Our DRO lathe will not only cut wood and plastic but is also rigid and accurate enough to cut aluminum and steel parts. This lathe is a desktop-size machine with full-size machine precision and accuracy.

Using the Digital Readout on the Tabletop Lathe

The display shows the position of each axis in relation to a zero point that you establish. Inch versions show position to three and a half decimal places or to within .0005″. Metric versions show position to within .01 mm. Backlash can be electronically eliminated by setting its measured value into the readout box for each axis. When handwheel rotation changes direction, the backlash value is electronically subtracted before the readout counts in the other direction.

The ease with which distance and direction can be kept track of with this system will add a new level of enjoyment to your machining. It also helps eliminate some of the tedious jobs of keeping track of handwheel revolutions and thereby helps eliminate errors.

NOTE: The unit does not translate dimensions from inch to metric. It must be initialized to work with the pitch of the leadscrew to which the handwheel is attached.

220-240 Volt Electrical Current

The DRO power supply automatically switches from 120V to 240V for countries with 220-240 volt electrical current. You may need to use a wall socket adapter if you use the power supply in a country outside North America.

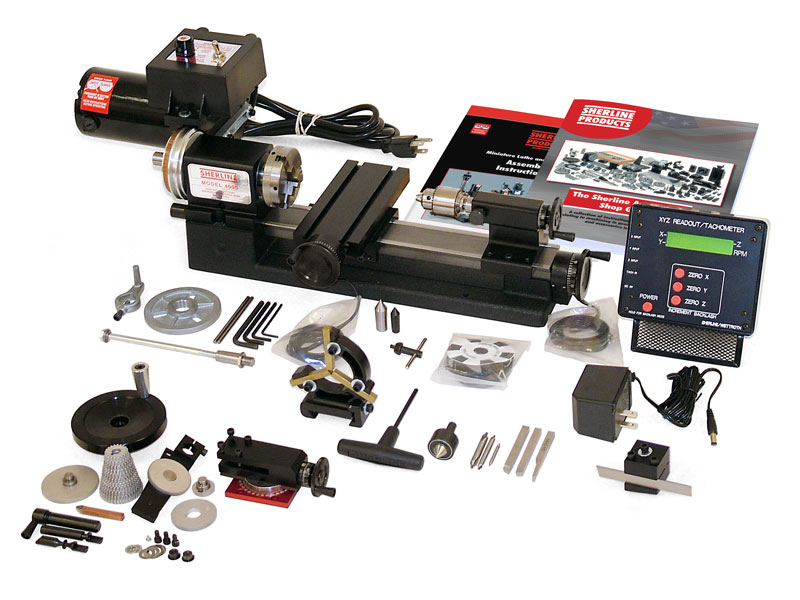

Standard equipment for the DRO Tabletop Lathe includes:

- A powerful 90V DC motor with electronic speed controller*

- 2.75″ (70mm) x 6.0″ (152mm) crosslide

- 15″ (381mm) steel bed to allow 8″ (203mm) between centers

- Digital readout box with LCD display, RPM sensor, power supply, cables, stand, and all necessary mounting hardware. No hole drilling is required.

- Special handwheels are supplied with DRO machines. These handwheels can be reset to zero electronically with the push of a button on the DRO display box. Sherline DRO lathes are outfitted with the special DRO 2″ (51mm) handwheels on the leadscrew and crosslide feed screw and a standard 1-5/8″ (41mm) handwheel on the tailstock. Each handwheel has laser-engraved aluminum handwheel collars.

- Pulleys, drive belt, faceplate, lathe dog, two dead centers, three hexagonal keys, tool post, sharpened high-speed steel cutting tool, eight-foot three-wire power cord, and instruction manual.

* Not included with lathe without motor and speed control

The C Package includes:

- 2.5″ 3-jaw self-centering chuck

- 1/4″ tailstock drill chuck w/ key, #0 Morse arbor, #1 Morse arbor with drawbolt

- Steady rest

- Live Center

- Compound Slide

- Rear Mount Cutoff Tool and Holder

- 3-pc 1/4″ HSS Cutting Tool Set (LH, RH, Boring)

- 5/32″ T-driver

- 3-pc Center Drill Set

- Sherline Accessories Shop Guide Book

- Thread Cutting Attachment

Other ordering options:

Similar to the XYZ bases for our mills, you can now order the lathe without the headstock, motor, or speed control. Please see the selections in the drop-down menu above.