- CNC-ready with factory-installed stepper motor mounts (X and Z axes)

- Turns parts up to 3.5″ (90 mm) diameter over the bed

- 17″ (430 mm) bed provides extended travel for longer workpieces

- 8″ (200 mm) crosslide for increased tool reach

- Precision-machined dovetail slides with adjustable gibs and backlash

- High-accuracy spindle and headstock used across all Sherline lathes

- Manual control possible with included handwheels

- Compatible with Sherline’s full line of accessories

- Made in the USA

- Model making and miniatures

- Prototyping and custom part production

- Educational CNC training programs

- Hobbyist and light industrial use

- A powerful 90V DC motor with electronic speed controller

- 12″ base with laser-engraved scales

- Brass leadscrew cover that keeps chips off the rear of the Y-axis leadscrew

- 2.75″ (70 mm) x 13.0″ (330 mm) table with laser-engraved scales and two T-slots

- 1.235″ headstock spacer block

- Resettable, zero-adjustable handwheels that can be mounted to the end of the stepper motors to maintain manual control when needed:

- (2) 2″ (51 mm) handwheels on X- and Y-axes

- (1) 2-1/2″ (63 mm) handwheel on Z-axis

- All with laser-engraved aluminum collars

- NOTE: CNC-ready machines cannot be operated manually unless double-shaft stepper motors are installed.

- ¼” Drill Chuck w/ key, #1 Morse arbor with drawbolt

- Pulleys, drive belt, three hexagonal keys, spindle bars, gib removal tool, eight-foot three-wire power cord, and instruction manual

- Oil reservoirs on the X/Y axes and the Z axis help keep critical parts lubricated. These were initially developed for CNC machines that run constantly for hours on end but can benefit manual machines as well

- The headstock pivots up to 90° left or right.

- The column bed also rotates side to side up to 90°, enabling angled drilling.

- A specialized knuckle joint allows the column to tilt front to back.

- The ram-style column base can swing side to side up to 90°, offering even greater flexibility.

- Loosening the column cap lets the ram move in and out, providing over 5.5″ of additional travel.

- A powerful 90V DC motor with electronic speed controller

- 14″ base with laser-engraved scales

- Brass leadscrew cover that keeps chips off the rear of the Y-axis leadscrew

- 2.75″ (70 mm) x 13.0″ (330 mm) table with laser-engraved scales and two T-slots

- 2" column riser block

- Resettable, zero-adjustable handwheels that can be mounted to the end of the stepper motors to maintain manual control when needed:

- (2) 2″ (51 mm) handwheels on X- and Y-axes

- (1) 2-1/2″ (63 mm) handwheel on Z-axis

- All with laser-engraved aluminum collars

- NOTE: CNC-ready machines cannot be operated manually unless double-shaft stepper motors are installed.

- ¼” Drill Chuck w/ key, #1 Morse arbor with drawbolt

- Pulleys, drive belt, three hexagonal keys, spindle bars, gib removal tool, eight-foot three-wire power cord, and instruction manual

- Oil reservoirs on the X/Y axes and the Z axis help keep critical parts lubricated. These were initially developed for CNC machines that run constantly for hours on end but can benefit manual machines as well

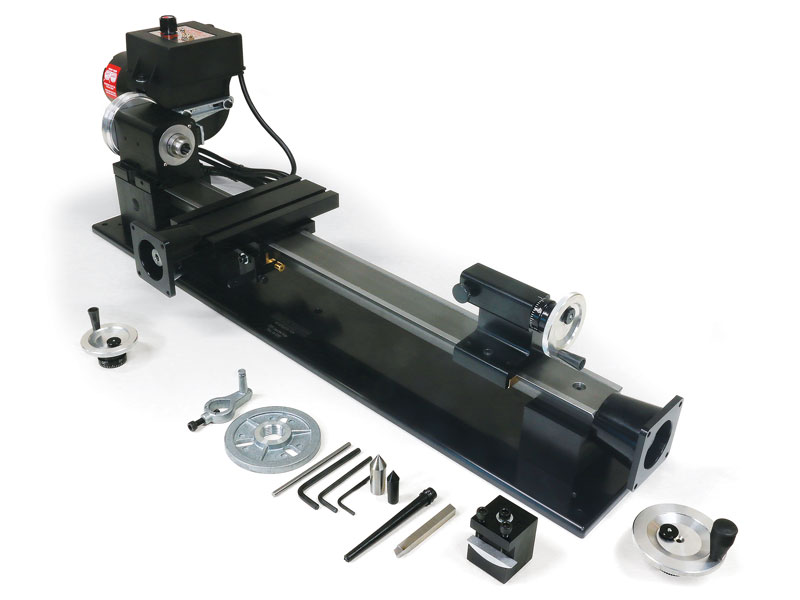

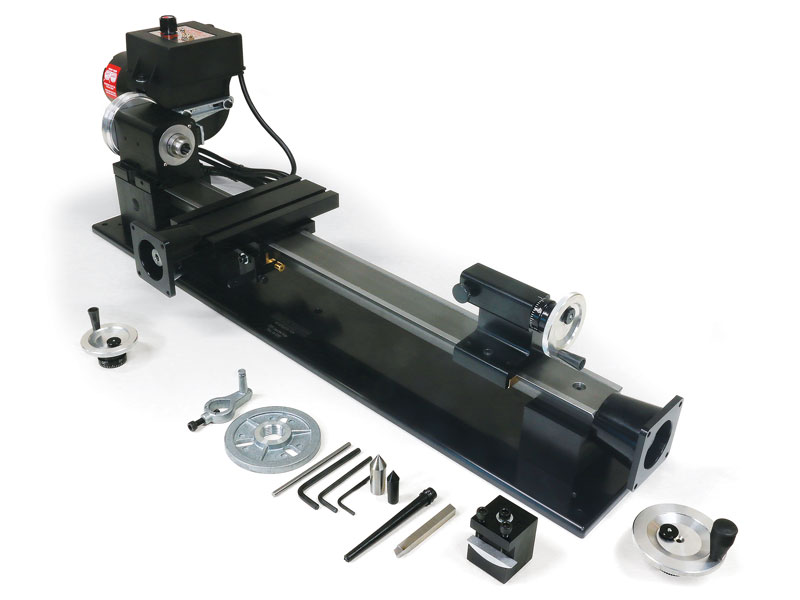

17″ CNC-Ready Lathe

The Sherline 17" CNC Lathe is a precision benchtop machine designed for small, detailed, and accurate turning applications. Built on Sherline’s proven lathe platform, this CNC-ready version includes factory-installed stepper motor mounts on both the X and Z axes - allowing you to add your own stepper motors and controller for complete CNC control.

With a 17" long bed, 8" crosslide, and a working diameter capacity of up to 3.5" over the bed, this lathe provides the versatility needed for prototyping, small-part production, model engineering, R&D, and teaching environments. The rigid aluminum/steel construction, dovetail slides, and adjustable backlash compensation ensure repeatable accuracy on even the smallest parts.

All CNC-ready Sherline lathes include the same high-quality headstock, spindle, and bearings used in our manual models, giving you excellent spindle concentricity for demanding turning operations. The machine still allows for full manual operation when needed - simply turn the handwheels for quick setup or manual machining tasks.

Features:

Ideal Applications:

Note: This is a CNC-ready lathe. Stepper motors and CNC controller are sold separately. For a fully assembled and tested system, see our complete CNC lathes.

12″ CNC-Ready Mill

Our CNC-ready tabletop mill is ideal for customers seeking a compact CNC milling solution for producing small, precision parts. This mill offers full-size machine accuracy in a desktop footprint. Despite its size, it’s capable of cutting wood, plastic, aluminum, and even steel with impressive rigidity and precision.

CNC-ready mills come with factory-installed stepper motor mounts in place of handwheels and are ready for you to add your own stepper motors and CNC controls. Please note: these are not turn-key systems and cannot be operated until motors and controls are installed. CNC-ready machines do not include stepper motors, a computer, or CNC software.

Sherline recommends dual-shaft stepper motors so manual control is still possible using the included handwheels, which mount to the rear shaft once the motors are installed. Sherline also offers high-quality stepper motors and CNC components to complete your system.

Additionally, you can explore various aftermarket suppliers for compatible motors, drivers, and software. Visit our CNC Dealers page for a list of suppliers and links to their websites.

Note on Ordering a Metric Mill – Most Sherline cutting tool, such as center drills, are offered in fractional sizes. If you opt for a metric machine with metric collets or holders, you’ll need to order compatible fractional-size holders to use these tools effectively.

Standard Equipment for the 12″ Deluxe Tabletop Mill

14″ CNC-Ready Mill

The 8-Direction CNC-Ready Milling Machine is one of the most versatile mills Sherline offers. In addition to standard X-, Y-, and Z-axis movement, this model provides five additional directions of headstock adjustment—allowing you to position the spindle for drilling or milling operations from nearly any angle.

With this wide range of movement, the machining possibilities are nearly limitless within the compact work envelope of the machine. The 14″ base also increases Y-axis travel by 2″ compared to the Model 5400 mill, making it a powerful tool for advanced miniature machining applications.

The 8-Direction benchtop mill is ideal for users who need a small, precision milling machine capable of high-accuracy work. Like all Sherline mills, it is made in the USA and supported by unmatched customer service. Despite its compact size, this 14″ benchtop mill is engineered to handle wood, plastic, aluminum, and even steel—delivering full-size machine precision in a desktop footprint.

CNC-ready mills come with factory-installed stepper motor mounts in place of handwheels and are ready for you to add your own stepper motors and CNC controls. Please note: these are not turn-key systems and cannot be operated until motors and controls are installed. CNC-ready machines do not include stepper motors, a computer, or CNC software.

Sherline recommends dual-shaft stepper motors so manual control is still possible using the included handwheels, which mount to the rear shaft once the motors are installed. Sherline also offers high-quality stepper motors and CNC components to complete your system.

Additionally, you can explore various aftermarket suppliers for compatible motors, drivers, and software. Visit our CNC Dealers page for a list of suppliers and links to their websites.

Note on Ordering a Metric Mill – Most Sherline cutting tool, such as center drills, are offered in fractional sizes. If you opt for a metric machine with metric collets or holders, you’ll need to order compatible fractional-size holders to use these tools effectively.