- A powerful 90V DC motor with electronic speed controller

- 12″ base with laser-engraved scales

- Brass leadscrew cover that keeps chips off the rear of the Y-axis leadscrew

- 2.75″ (70 mm) x 13.0″ (330 mm) table with laser-engraved scales and two T-slots

- 1.235″ headstock spacer block

- Resettable, zero-adjustable handwheels that can be mounted to the end of the stepper motors to maintain manual control when needed:

- (2) 2″ (51 mm) handwheels on X- and Y-axes

- (1) 2-1/2″ (63 mm) handwheel on Z-axis

- All with laser-engraved aluminum collars

- NOTE: CNC-ready machines cannot be operated manually unless double-shaft stepper motors are installed.

- ¼” Drill Chuck w/ key, #1 Morse arbor with drawbolt

- Pulleys, drive belt, three hexagonal keys, spindle bars, gib removal tool, eight-foot three-wire power cord, and instruction manual

- Oil reservoirs on the X/Y axes and the Z axis help keep critical parts lubricated. These were initially developed for CNC machines that run constantly for hours on end but can benefit manual machines as well

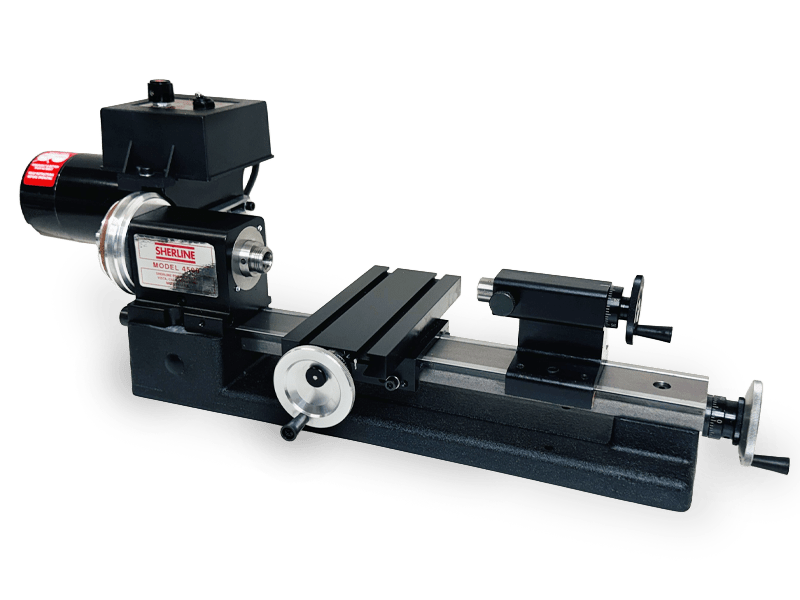

12″ CNC-Ready Mill

Our CNC-ready tabletop mill is ideal for customers seeking a compact CNC milling solution for producing small, precision parts. This mill offers full-size machine accuracy in a desktop footprint. Despite its size, it’s capable of cutting wood, plastic, aluminum, and even steel with impressive rigidity and precision.

CNC-ready mills come with factory-installed stepper motor mounts in place of handwheels and are ready for you to add your own stepper motors and CNC controls. Please note: these are not turn-key systems and cannot be operated until motors and controls are installed. CNC-ready machines do not include stepper motors, a computer, or CNC software.

Sherline recommends dual-shaft stepper motors so manual control is still possible using the included handwheels, which mount to the rear shaft once the motors are installed. Sherline also offers high-quality stepper motors and CNC components to complete your system.

Additionally, you can explore various aftermarket suppliers for compatible motors, drivers, and software. Visit our CNC Dealers page for a list of suppliers and links to their websites.

Note on Ordering a Metric Mill – Most Sherline cutting tool, such as center drills, are offered in fractional sizes. If you opt for a metric machine with metric collets or holders, you’ll need to order compatible fractional-size holders to use these tools effectively.