| Parameters | Logic high levels should be greater than 2 volts. |

|---|---|

| Logic low should be less than 1/2 volt. | |

| Step pulses are active low. | |

| Step pulses should be at least 22 microseconds long. | |

| The lines labeled as LinuxCNC inputs or outputs can be disregarded in other systems. | |

| For use with software other than LinuxCNC, make sure your software addresses the correct I/O lines for step and direction as shown below. Sherline is not able to provide assistance for other programs. For help with the LinuxCNC software, see http://www.linuxcnc.org/ | |

| We recommend at least an 800 MHz Pentium class computer or faster for use with the frequency mode. | |

| In operation, the power to the motors will be reduced to half current after 3 seconds of inactivity. This can be changed to 1/4 power with a jumper on H1. | |

| DB25 pin out | 1 – Input from LinuxCNC (may be ignored in other systems) |

| 2 – X Direction | |

| 3 – X Step | |

| 4 – Y Direction | |

| 5 – Y Step | |

| 6 – Z Direction | |

| 7 – Z Step | |

| 8 – A Direction | |

| 9 – A Step | |

| 10 – NC | |

| 11 – Output to LinuxCNC (may be ignored in other systems) | |

| 12 – Output to LinuxCNC, XYZ home (may be ignored in other systems) | |

| 13 – NC | |

| 14 – Input from LinuxCNC, C1 (may be ignored in other systems) | |

| 16 – Input from LinuxCNC, C2 (may be ignored in other systems) | |

| 17 – NC | |

| 18-25 – Ground. | |

| Headers on PC board | H1 – Will reduce current to 1/4 after 3 seconds |

| H2 – Unimplemented H3 – Will remove power from drivers immediately (panic stop) | |

| RESET – Will hold the drivers in reset condition | |

| Motor Connectors | 5-pin DIN male |

| Five to 30 volts (better performance at higher voltage) | |

| 2 amp unipolar configuration | |

| 800 steps per revolution (microstepping), equates to 16,000 steps/inch with .050″ pitch leadscrew |

Back to Replacement Parts

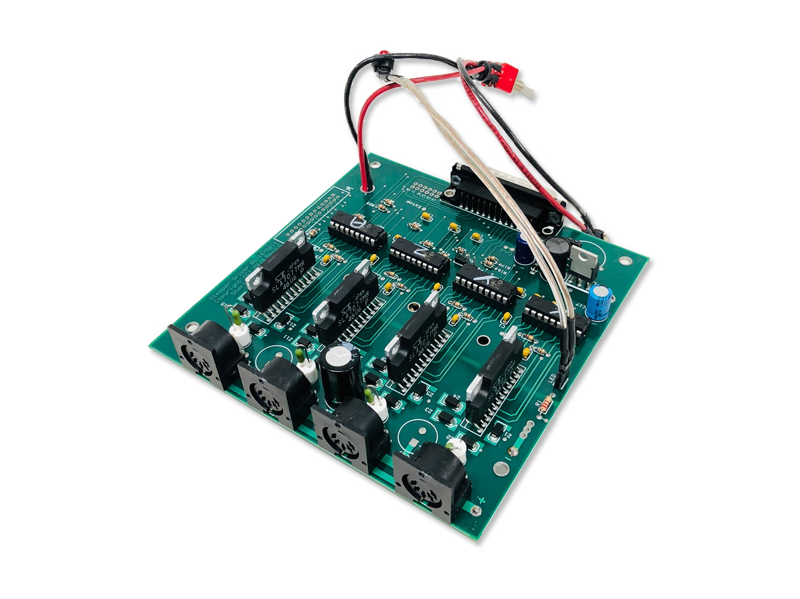

CNC Controller Board

With removable fuses

CLICK HERE for the fuse replacement instructions

-

SKU: 87625-09

Category: Replacement Parts

Related products

- Built-in Driver box (Converts g-code to steps to run DC stepper motors)

- Output cables for X, Y, Z, and A pre-wired with DIN plugs for stepper motors

- Keyboard and mouse (you supply the monitor)

- Processor Speed: 2 GHz or faster

- RAM: 2 GB

- Hard Drive: 500 GB

- Internal drive: DVD-RW

- External drive: 4 GB USB Flash drive for transferring g-code files

- Current: Internal switches are set to 110VAC but can be reset for operation with 230 VAC

- Installed software: Ubuntu 12.04 Linux-based OS with Linux CNC 2.6.11 4-axis CNC software.

- 90-day warranty on CNC and computer-related components.

4-Axis CNC Driver Box

In designing our CNC systems, we fitted the driver board and power supply directly inside the PC. For users who’d prefer to build their own setup or use a different PC, we offer this complete driver box and power supply as a standalone solution.

Housed in an anodized aluminum enclosure, this unit includes four stepper-motor drivers — labeled X, Y, Z and A — each terminating in a dedicated cable that plugs directly into the corresponding pre-wired Sherline stepper motor. The kit also includes a 6′ (approx.) DB-25 parallel cable to connect the box to your computer’s parallel port, and an externally-mounted 24 VDC power supply (included) that simply plugs into the driver box.