Product Description

Like those used on many of our large production machines, the mill tooling plate solves two main problems. It not only protects your mill’s table from damage (while also adding additional stiffness), but it also provides an inexpensive, modifiable surface for clamping work that is as flat as the machine’s original table. The best way to hold a part more securely is to add more clamping points rather than over-tightening the points you already have. The mill tooling plate allows you to easily do this. Like a lathe faceplate, the mill tooling plate should be looked at as somewhat disposable. It has a hole pattern predrilled to make it easy to clamp down the Sherline mill vise or the rotary table, but you should feel free to drill and tap whatever additional holes are needed to meet your clamping and setup needs for a particular job. The plate is made from 6061-T6 aluminum that is accurately milled to 3/4″ thick, which is 1/4″ thicker than our standard P/N 3560 tooling plate. The surface is not anodized. Therefore, additional machining to the plate can be done to suit your unique needs.

NOTE: This tooling plate will mount on your table, but it will reduce your “throat depth” by 2″, and your overall Y-axis travel by 3.3″. A 12″ base will be reduced to 1.7″ of Y-axis travel, and a 14″ base will be reduced to 3.7″ of Y-axis travel (See Figure 1).

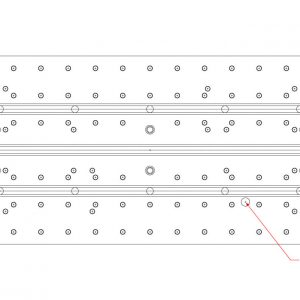

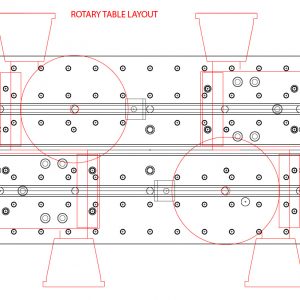

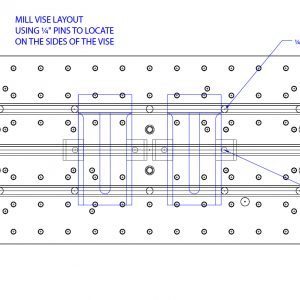

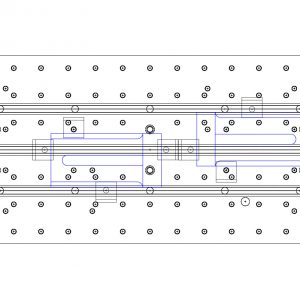

This 7″ x 18″ tooling plate is a larger version of the 7″ x 13″ tooling plate (P/N 3562) that comes standard with the 5800 NexGen Mill. In addition to an extensive pattern of 10-32 holes on 1-inch centers, the plate has three T-slots milled on its long axis to provide additional mounting capability. 10-32 holes are also provided as needed for mounting the Sherline P/N 3700 or 8700 rotary table. Provided with the plate are six 10-32 x 7/16″ mounting screws and T-nuts. Also provided are four 1/4″ diameter steel pins that go in locating holes in the bottom of the T-slots to help quickly locate parts parallel to the axis of the plate.

This fixture is not limited to use on Sherline tools. Like the rotary table and some other Sherline accessories, it could be useful on larger machines in your shop as well.

This tooling plate was designed to give our customers a larger work surface. The plate was designed primarily for the 5800 NexGen mill. When mounted on the 5800*, it will increase the usable machining area of the mill to a full 7″ x 18″ (that’s an additional 5.0″ in the Y-axis and 13.2″ in the X-axis). It can also be used on the 2000 mill, however, it limits the usable Y-axis travel to 2.85″. It has a hole pattern pre-drilled to make it easy to clamp down the Sherline mill vise. Additional holes were also added to accommodate the Sherline rotary table, but you should feel free to drill whatever additional holes are needed to meet your particular clamping and setup needs. The following images show how the Sherline rotary table and mill vise can be mounted on the 7″ x 13″ Mill Tooling Plate. (Click on images below for larger view.)

*NOTE: The tooling plate must be mounted with the oiler access hole in the front of the machine in order for it to align to the oiler body.