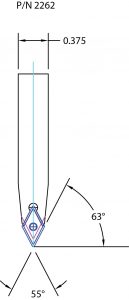

Straight Insert Tool Holder w/55° insert

This holder features a centered design (not offset to either side) and includes a 55° carbide insert, a hold-down screw, and a Torx key for installation. It has a 3/8″ square shank that fits standard 3/8″ tool posts. The straight tip design allows for general-purpose turning operations in either direction. The cutting tip is positioned 0.375″ from the bottom of the holder, which conforms to industry standards. The holder is constructed from case-hardened steel and finished with black oxide for enhanced durability and corrosion resistance.

Though more costly than traditional tools, each insert offers two usable cutting edges. When one edge becomes dull or chipped, simply rotate the insert 180° to access a new cutting surface—essentially providing two tools in one.

About the Carbide Inserts

While high-speed steel (HSS) tools remain the primary choice for miniature machine work due to their affordability and ease of resharpening, inserted-tip carbide tools offer significant advantages in specific applications. Carbide inserts excel in cutting harder materials, improving efficiency and tool life—making them invaluable in many professional machining environments.

Safety Note

Carbide inserts can produce extremely hot chips and may shatter under stress. Always wear appropriate eye protection and safety gear when using these tools.

Certain materials, such as tool steel, may form long, continuous chips that can wrap around the workpiece like steel wool. To minimize this, use a chip brush frequently or pause machining to remove chip buildup. These “bird’s nests” can ignite from hot chips, so maintain a clean workspace near the cutter.

4 interest-free payments of $16 with Affirm. Check your purchasing power

| Insert Holder Material | Case Hardened Steel |

|---|---|

| Body Coating | Black Oxide |

Related products

Carbide Inserts (thread, groove)

These Carbide inserts are used in the Insert Tool Holder and are used for either threading or grooving.

Thread Cutting

- 60° threading insert for cutting outside threads (P/N 22675)

- .031" insert (P/N 2269)

- .062" insert (P/N 2270)

- .094" insert (P/N 22694)

- .125" insert (P/N 22695)

- .031" radius insert (P/N 22692)

- .062" radius insert (P/N 22693)

RH 55° and 80° 3/8″ Boring Bars w/Carbide Inserts

These 3/8" diameter boring bars feature a carbide insert secured with a Torx® screw and come complete with a Torx wrench. Choose between:

-

A 55° right-hand insert, suitable for starting holes as small as 3/4", ideal for reaching sharp internal corners

-

An 80° insert, which fits into a smaller 1/2" hole and offers added strength for roughing operations

Each holder measures 3-1/4" long and can bore to a depth of just over 2" when properly secured with two set screws. Manufactured from durable 1144 Stressproof® steel with a black oxide finish, these tools are available individually or as a discounted set.

Why Choose Carbide Insert Tools?

While high-speed steel (HSS) remains common for small machine tools due to its low cost and resharpenability, carbide inserts offer significant advantages in demanding applications:

-

Longer-lasting edges when cutting hard metals like stainless steel, titanium, or abrasive materials such as carbon fiber

-

Faster cutting speeds and greater efficiency

-

Each insert can be rotated 180°, effectively giving you two cutting edges per insert

Although carbide inserts can't be resharpened, their durability and versatility make them a preferred choice in professional machine shops.

Note: The older straight-groove chip breaker insert is no longer available. Current inserts include the spider web-style chip breaker, as shown in the updated images here & here

LH 55° & 80° 3/8″ Boring Bars w/Carbide Inserts

These 3/8" diameter boring bars hold a carbide insert secured with a Torx screw. Each comes with either a 2-sided 55° or 80° carbide insert and Torx wrench. The 55° LH boring tool will fit into a 3/4" starting hole. The 80° holder will fit into a smaller 1/2" hole. The 80° holder offers a little more strength for roughing cuts while the 55° insert will cut into sharper corners. The 3-1/4" long holder can bore a hole a little over 2" deep with two fastening screws tightened on it. The holders are made from 1144 Stress-proof steel with a black oxide finish. Available individually.

Left Hand Boring Bars

These LH boring bars are not intended to be used for boring on a standard Sherline lathe, as the spindle is not reversible without electronic modifications. They were developed for a Sherline tool that is now in development where they will be used as a turning tool from the backside with the bit upside down. Watch for the introduction of this new “chucker” lathe soon.

Advantages of Using Carbide Insert Tools

Though relatively expensive, if a cutting edge of a carbide insert becomes dull or chipped, the insert can be removed and rotated 180° to expose two new cutting surfaces, providing, in effect, two tools for the price of one.

The primary method of cutting metal on miniature machine tools is usually with high-speed steel tools as they are inexpensive, easily resharpened and can be ground into "form" tools for special jobs. However, inserted tip carbide tools can be lifesavers for some jobs. Though more expensive and not able to be resharpened, carbide tools hold their cutting edge when cutting exotic metals like stainless steel or titanium or abrasive materials like carbon fiber and can speed up the cutting process. This is why they are used for most cutting tasks in the modern professional machine shop.

NOTE: A tool is named by the direction from which the chip leaves the tool; so a right-hand tool has its cutting edge on the left and the chip peels off to the right.