- Centroid Acorn CNC control board

- Acorn plug-and-play relay module (mounted and pre-wired)

- Internal wiring to DB9, DB25, and 2-wire Molex connectors

- Power supply, push-to-reset circuit breaker, and cooling fan

- External Ethernet port, power switch, and power LED

- Ethernet connection

- Power switch and power LED

- Cooling fan

- Three DB25 connectors:

- Sherline 4-axis driver box

- Aux 4-axis control for additional drives/axes

- Relay card

- Three DB9 connectors:

- Limit switches

- External encoder*

- Aux tool setter or touch probe (one at a time)

- Three 2-wire Molex connectors:

- E-stop button

- Spindle control

- Laser

- Dual logic power: 5 VDC and 24 VDC

- Input power: 100–120 VAC or 208–240 VAC, 50/60 Hz

- 15 ft shielded Ethernet cable (controller to PC)

- External E-stop with 2 ft cord

- The controller connects directly to Sherline 24 V stepper motors via the Sherline 4-axis driver box (P/N 8760).

- Not compatible with MASSO 36 V closed-loop stepper motors.

- For DIY users with their own motors/drives, use the “Aux 4-axis” DB25 connector. Wiring information for DIY customers is available under the Specifications/Downloads.

- Program directly from hand sketches or prints

- Import DXF files and generate G-code without separate CAD/CAM

- Ideal for new CNC users and those unfamiliar with traditional G-code programming

- Buys CNC-ready Sherline machines and installs their own motors, drives, and encoders.

- Purchase the base Sherline/Acorn CNC Controller (P/N 9400) without options and wire to your own hardware.

- Upgrading an existing Sherline CNC system including older OEM systems such as Denford, D&M, LabVolt, Paxton-Patterson, or Light Machines. For a sample Denford/Sherline Microlathe conversion using Acorn, see: Centroid Denford/Sherline Microlathe Conversion

- If you already have a Sherline Linux PC or 4-axis driver box, configure the controller

with:

- Spindle Control Isolator Board

- External Encoder kit for your headstock (Standard or 3C)

- Wants a complete Sherline system: CNC-ready machine, 24 V stepper motors, 4-axis driver box, spindle control isolator board, and external encoder.

- The Sherline/Acorn Controller is designed to support all of these configurations.

- To control spindle speed via G-code, you must have a motor drive or the Spindle Control Isolator Board and an external encoder installed.

- These components work together to accurately acquire and control spindle RPM.

- If you do not include the Spindle Control Isolator Board at the time of purchase, adding it later will require returning the controller to Sherline for installation. Email orders@sherline.com for return instructions.

- Built-in Driver box (Converts g-code to steps to run DC stepper motors)

- Output cables for X, Y, Z, and A pre-wired with DIN plugs for stepper motors

- Keyboard and mouse (you supply the monitor)

- Processor Speed: 2 GHz or faster

- RAM: 2 GB

- Hard Drive: 500 GB

- Internal drive: DVD-RW

- External drive: 4 GB USB Flash drive for transferring g-code files

- Current: Internal switches are set to 110VAC but can be reset for operation with 230 VAC

- Installed software: Ubuntu 12.04 Linux-based OS with Linux CNC 2.6.11 4-axis CNC software.

- 90-day warranty on CNC and computer-related components.

- Keyboard and mouse (you supply the monitor)

- Processor Speed: 2 GHz or faster

- RAM: 2 GB

- Hard Drive: 500 GB

- Internal drive: DVD-RW

- External drive: 4 GB USB Flash drive for transferring g-code files

- Current: Internal switches are set to 110VAC but can be reset for operation with 230 VAC

- Installed software: Ubuntu 12.04 Linux-based OS with Linux CNC 2.6.11 4-axis CNC software.

- 90-day warranty on CNC and computer-related components.

-

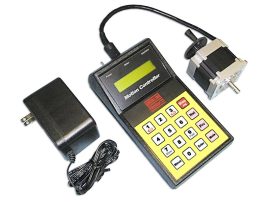

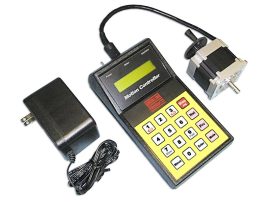

Linear Controller with Keypad

-

Power Supply

-

DVD: Linux operating system (Ubuntu v12.04) with LinuxCNC software (v2.6.11)

-

CD: Installation and troubleshooting instructions, along with free or low-cost utilities, including AutoEditNC, ACE Converter, MeshCAM, DeskEngrave, Freemill, Inkscape, and FreeCAD

-

Linear controller with keypad

-

Power supply

-

#23 frame size stepper motor

-

Cables

-

Complete instructions

Sherline/Acorn CNC Controller

[icon icon=icon-chevron-down size=14px color=#000 ] Controller Features

Custom control housing includes:[icon icon=icon-chevron-down size=14px color=#000 ] Compatibility & Connection Options

[icon icon=icon-chevron-down size=14px color=#000 ] Software & Conversational CAM

A free version of Centroid CNC12 is included with each Acorn kit for initial setup. However, it is strongly recommended that you purchase the Centroid Acorn “Pro” CNC12 Software License to unlock full conversational CAM (Intercon). Use the options below or visit: CLICK HERE for Acorn “Pro” CNC12 Software License details Intercon Conversational CAM:[icon icon=icon-chevron-down size=14px color=#000 ] Typical Use Cases

DIY Customer[icon icon=icon-chevron-down size=14px color=#000 ] Important Notes for Spindle Control

LinuxCNC Computer System with Driver Box

LinuxCNC Computer System without Driver Box

4-Axis CNC Driver Box

CNC Linear Controller with Power Supply

This stand-alone controller features an integrated keypad for easy programming and controls the operation of the connected stepper motor—no external computer or CNC system is required.

An 8-pin mini-DIN cable allows multiple controllers to be connected in a daisy-chain configuration. Each unit can send and receive signals to operate in sequence, enabling multi-axis motion without a master CNC controller. The controllers can also interface with existing CNC systems for more complex setups.

Each controller supports two independent programs, with up to 40 steps per program. Each step can define travel distance, direction, speed, and whether to pause or automatically continue to the next command.

The linear controller can also be daisy-chained with Sherline’s rotary controller, enabling combined linear and rotary motion. This simplifies more advanced tasks—such as gear cutting—without requiring any G-code knowledge beyond the simple keypad inputs.

Included with the Linear Controller:

Power Supply Specifications:

The included power supply is compatible with 110–240 VAC and automatically adjusts to local voltage, making it suitable for use worldwide. (Earlier versions of this product included a 110 VAC-only power supply.)

Sherline Linux OS/LinuxCNC Software

The discs include the following items and require a PC equipped with a CD/DVD drive:

CNC Linear Controller with Stepper Motor

This stand-alone controller is fully programmable via its integrated keypad and directly controls the stepper motor to which it is connected. The stepper motor can be applied to any axis of a CNC-Ready Sherline machine.

An 8-pin mini-DIN cable allows multiple controllers to be connected in a “daisy-chain” configuration. Controllers can signal one another to operate in sequence, enabling complex, multi-axis movements without the need for a computer or master CNC controller. The system can also be used alongside existing CNC controllers. Each controller stores two independent programs, with up to 40 operations per program. For each operation, you can define travel distance, direction, feed rate, and whether the sequence pauses or proceeds to the next step.

The linear controller can also be daisy-chained with Sherline’s rotary controller, enabling coordinated rotary and linear motion. This allows users to easily perform advanced operations—such as gear cutting—without requiring CNC programming skills beyond simple keypad inputs.

Included with the CNC Linear Controller:

Note: To add CNC linear control to an axis on a Sherline machine that does not have a stepper motor mount, see P/N 8850.

Power Supply Compatibility:

The included power supply operates on 110–240 VAC and automatically adjusts for global use (220–240V). Earlier versions of this product shipped with a 110 VAC-only power supply.