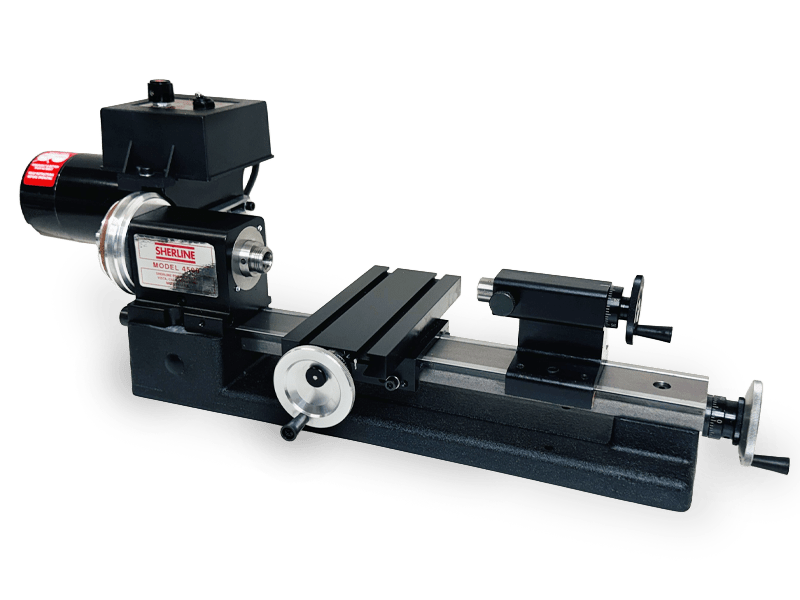

The 8″ tabletop lathe is an ideal precision tool for jewelers and gem cutters working on small, detailed components such as rings, settings, mandrels, bezels, bushings, and custom fixtures. It can turn parts up to 3.5″ in diameter over the bed or 1.88″ over the carriage, with 8″ of distance between centers, providing ample capacity for most jewelry and lapidary work without unnecessary machine size.

For jewelry applications, we often recommend the 8″ tabletop lathe over our 17″ model. The additional bed length of the 17″ lathe is rarely needed for typical jeweler or gem-cutting tasks, and its longer layout requires reaching farther to operate the Z-axis handwheel. The compact design of the 8″ lathe keeps both handwheels close to the work area, allowing for greater control, improved ergonomics, and more precise hand-fed cuts during fine finishing operations.

The lathe features an electronic speed control that provides continuously variable spindle speeds from 70 to 2,800 RPM without belt changes, making it easy to dial in the correct speed for delicate materials and small-diameter tools. A secondary pulley position is available when additional low-RPM torque is needed for tougher materials or heavier cuts. Despite its compact footprint, the machine is rigid and stable, delivering the smooth, controlled operation required for jewelry-scale precision.

Typical Jewelry & Gem-Cutting Applications

- Turning and sizing ring blanks and bands

- Machining ring mandrels and expanding mandrels

- Cutting and finishing bezels, settings, and prongs

- Making collet-held parts and small precision components

- Truing and modifying stone setting tools

- Fabricating custom jigs, fixtures, and specialty tools

- Light turning of precious and non-precious metals

- Working with wax, plastic, aluminum, and steel for prototypes and tooling

Designed for jewelers seeking a professional-grade mini lathe, this tabletop machine combines desktop convenience with true machine-tool accuracy. Made in the USA and backed by knowledgeable customer support, it is capable of machining wood, plastic, aluminum, and steel, making it a versatile addition to any jewelry or gem-cutting workshop. Its small size makes it especially well suited for space-limited studios and home shops, and it can be easily stored when not in use.