|

|

Always wear safety glasses when operating machine tools. |

|

Download PDF Installing High-Torque Stepper Motors on Ball Screw Machines |

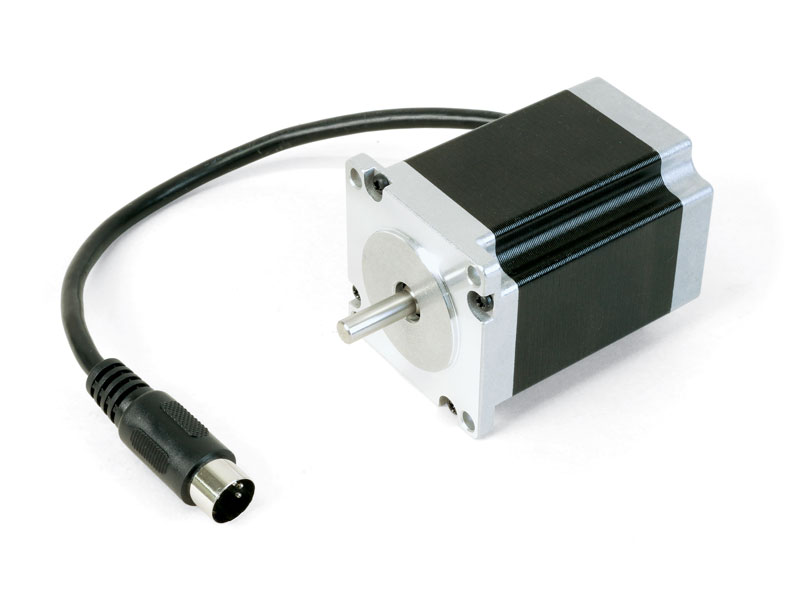

High-Torque Stepper Motor

Sherline’s high-torque stepper motor features the same NEMA 23 frame size as our standard stepper motor but delivers over 75% more torque – ideal for increased cutting feed rates and better performance on the Z-axis, where it can handle the added weight of the motor and headstock. Note that maximum rapid feed rate remains unchanged.

Important Compatibility Note: Due to the increased torque, these motors require an updated CNC coupler (P/N 671052, sold separately). If upgrading from systems using the discontinued coupler (P/N 67105), ensure you purchase the correct replacement.

Rated at 2 amps, these motors are fully compatible with all Sherline CNC machines, including complete CNC systems, our 4-axis driver box, CNC rotary tables and our linear and rotary motion controllers. No additional power supply upgrades are needed.

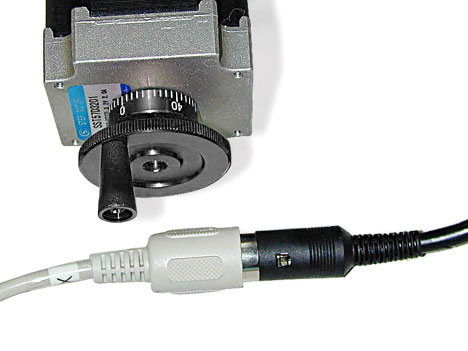

Dual-shaft design allows handwheel operation for manual control. Flats are precision-ground on both ends to secure handwheels and couplers via set screws. When used with Sherline motor mounts, the shaft end engaging the coupler must have a flat to prevent damage from the set screw. This may not be necessary in non-Sherline applications.

Each motor includes a six-lead cable with a 5-pin connector, pre-wired to interface seamlessly with Sherline’s CNC equipment, making setup fast and easy – just plug in and go.

-

| Frame size | NEMA #23 |

|---|---|

| Shaft | 1/4″ diameter, dual shafts |

| Holding Torque | 1.35 N.m (Newton meters) 13.756 kg-cm (kilogram centimeter) 191.17 oz/in (ounce inch) 11.948 in/lb (inch pound) |

| Maximum RPM | 530 RPM |

| Axial-Force | Fa=15 N Max., or 3.37 lbf Max. |

| Radial-Force | Fr=75 N Max., or 16.86 lbf Max. |

| Rotor inertia | 480 g-cm2 |

| Voltage | 4.5 V DC |

| Current | 2 A |

| Step Angle | 1.8° (200 steps/rev) |

Video instructions on how to remove and install Sherline CNC Stepper Motors

Removing Stepper Motors

Installing Stepper Motors

Aligning the Stepper Motor to the Ball Screw

Related products

10″ Tabletop Mill Package A – CNC-Ready