Product Description

| INDUSTRY STANDARD | #1 |

| INCLUDED ANGLE | 60° |

| TOOL MATERIAL | High Speed Steel |

| FINISH COATING | Bright Finish |

| DRILL DIAMETER | 3/64″ |

| BODY DIAMETER | 1/8″ |

| HARDNESS | 58 to 60 RC |

| OVERALL LENGTH | 1-1/4″ |

| SIZE | # 1 |

.046 tip diameter, 1/8″ shank diameter

-

| INDUSTRY STANDARD | #1 |

| INCLUDED ANGLE | 60° |

| TOOL MATERIAL | High Speed Steel |

| FINISH COATING | Bright Finish |

| DRILL DIAMETER | 3/64″ |

| BODY DIAMETER | 1/8″ |

| HARDNESS | 58 to 60 RC |

| OVERALL LENGTH | 1-1/4″ |

| SIZE | # 1 |

Lathe tools—also known as tool bits—are the cutting tools used for turning, facing, and other operations on a lathe. The most commonly used are high-speed steel (HSS) tools, which are suitable for machining a wide range of materials including wood, plastic, aluminum, brass, and steel. HSS tools maintain their hardness at temperatures up to 1000°F (588°C), making proper depth of cut, cutting speed, and feed rate essential for optimal performance.

One of the key advantages of HSS tools is how easily they can be resharpened using a standard aluminum oxide grinding wheel. Once sharpened, they retain a keen cutting edge through extended use.

Each Sherline lathe comes with a pre-sharpened 1/4" HSS cutting tool. Pre-ground tool sets—featuring right-hand, left-hand, and boring tools—are also available. However, for long-term savings and flexibility, learning to grind your own tools from blanks is recommended. Custom-shaped tools can be saved for repeat jobs or re-ground for new applications.

Lathe tools—often referred to as tool bits—are the primary cutting tools used for turning and facing operations on a lathe. The most common type is made from high-speed steel (HSS), which is suitable for machining a wide range of materials, including wood, plastic, aluminum, brass, and steel. HSS tool blanks are relatively inexpensive and can maintain their hardness at temperatures up to 1000°F (588°C), making proper control of depth of cut, cutting speed, and feed rate essential.

A major advantage of HSS tools is how easily they can be sharpened. They can be shaped and resharpened using a standard aluminum oxide grinding wheel and, once sharpened, will hold their edge for a long time.

NOTE: A lathe tool is named for the direction the chip exits the tool. A right-hand tool has its cutting edge on the left, causing the chip to peel off to the right.

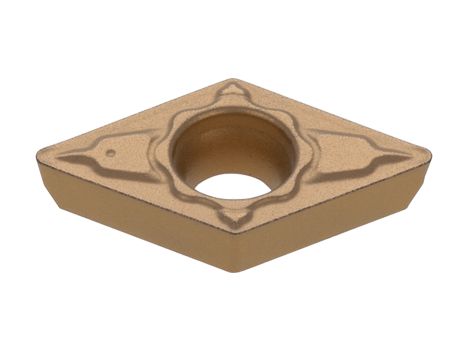

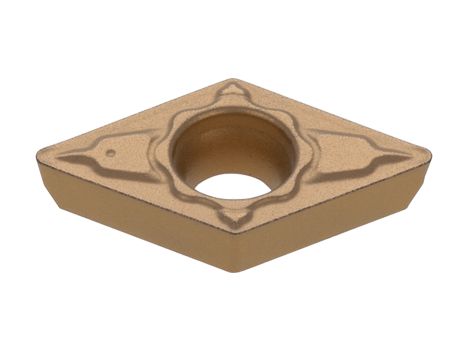

While not inexpensive, carbide inserts offer excellent value—each insert provides four cutting edges, significantly reducing the need for frequent sharpening and saving valuable time.

Carbide cutters perform well on hard-to-machine materials like cold-rolled steel and are also effective on aluminum, brass, and leaded steels, offering exceptional durability. However, for the finest finishes on softer metals, a well-sharpened high-speed steel tool still delivers superior results.

This is the 10-pack of replacement carbide inserts for the following tool holders: