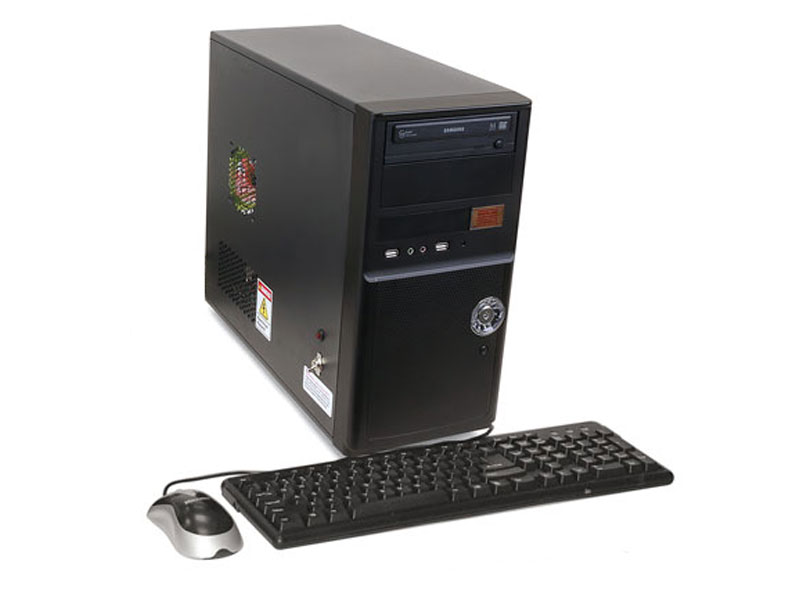

LinuxCNC Computer System with Driver Box

- Built-in Driver box (Converts g-code to steps to run DC stepper motors)

- Output cables for X, Y, Z, and A pre-wired with DIN plugs for stepper motors

- Keyboard and mouse (you supply the monitor)

- Processor Speed: 2 GHz or faster

- RAM: 2 GB

- Hard Drive: 500 GB

- Internal drive: DVD-RW

- External drive: 4 GB USB Flash drive for transferring g-code files

- Current: Internal switches are set to 110VAC but can be reset for operation with 230 VAC

- Installed software: Ubuntu 12.04 Linux-based OS with Linux CNC 2.6.11 4-axis CNC software.

- 90-day warranty on CNC and computer-related components.

Prior to January, 2005, Redhat version 2.xx was installed. From January, 2005 to September, 2009, Debian version 4.xx was installed. Starting in October, 2009 Ubuntu version was installed. Our 6.0 version of Ubuntu with “Lucid” build installed starting February, 2010. Debian wheezy 2017. Current software as of 2018 is Ubuntu 12.04 with Linux CNC 2.6.11

The most up-to-date version of the instructions can be found at CNC 7 Instructions. Instructions for Debian systems purchased between January 1, 2005, and September 17, 2009, can be found at CNC 4 Instructions. For those using a system purchased before January 1, 2005, instructions for the 2.xx Redhat version can be found on the Sherline CNC Instructions web page.

-

Related products

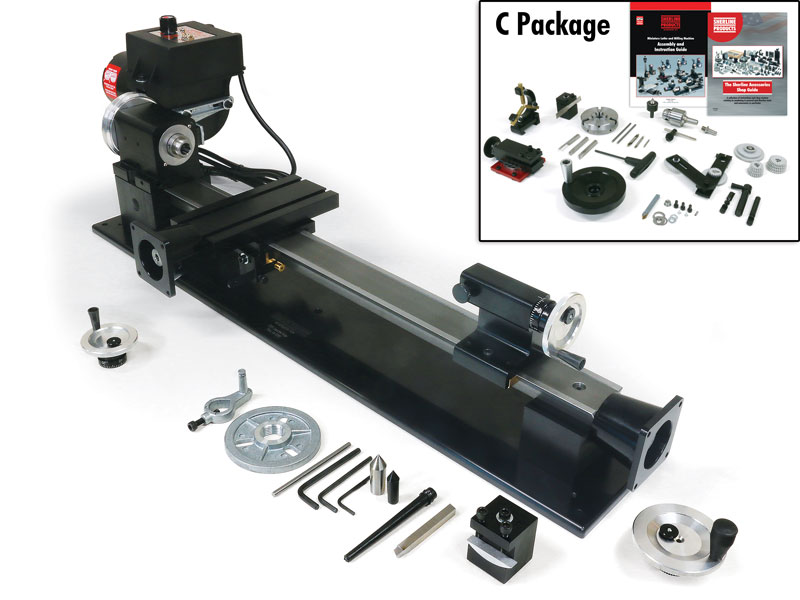

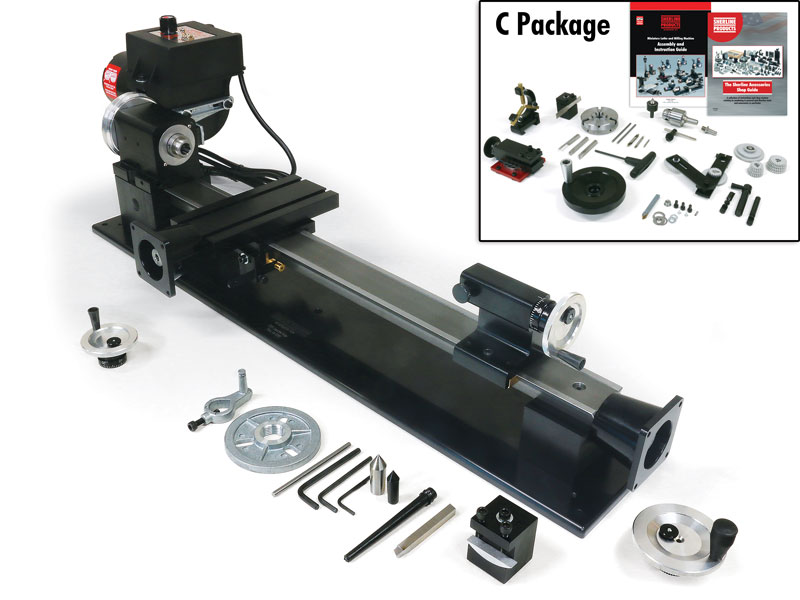

17″ Benchtop Lathe Package C – CNC Ready

14″ CNC-Ready Mill

The 8-Direction CNC-Ready Milling Machine is one of the most versatile mills Sherline offers. In addition to standard X-, Y-, and Z-axis movement, this model provides five additional directions of headstock adjustment—allowing you to position the spindle for drilling or milling operations from nearly any angle.

- The headstock pivots up to 90° left or right.

- The column bed also rotates side to side up to 90°, enabling angled drilling.

- A specialized knuckle joint allows the column to tilt front to back.

- The ram-style column base can swing side to side up to 90°, offering even greater flexibility.

- Loosening the column cap lets the ram move in and out, providing over 5.5″ of additional travel.

With this wide range of movement, the machining possibilities are nearly limitless within the compact work envelope of the machine. The 14″ base also increases Y-axis travel by 2″ compared to the Model 5400 mill, making it a powerful tool for advanced miniature machining applications.

The 8-Direction benchtop mill is ideal for users who need a small, precision milling machine capable of high-accuracy work. Like all Sherline mills, it is made in the USA and supported by unmatched customer service. Despite its compact size, this 14″ benchtop mill is engineered to handle wood, plastic, aluminum, and even steel—delivering full-size machine precision in a desktop footprint.

CNC-ready mills come with factory-installed stepper motor mounts in place of handwheels and are ready for you to add your own stepper motors and CNC controls. Please note: these are not turn-key systems and cannot be operated until motors and controls are installed. CNC-ready machines do not include stepper motors, a computer, or CNC software.

Sherline recommends dual-shaft stepper motors so manual control is still possible using the included handwheels, which mount to the rear shaft once the motors are installed. Sherline also offers high-quality stepper motors and CNC components to complete your system.

Additionally, you can explore various aftermarket suppliers for compatible motors, drivers, and software. Visit our CNC Dealers page for a list of suppliers and links to their websites.

Note on Ordering a Metric Mill – Most Sherline cutting tool, such as center drills, are offered in fractional sizes. If you opt for a metric machine with metric collets or holders, you’ll need to order compatible fractional-size holders to use these tools effectively.

Standard Equipment for the 14″ 8-Direction Tabletop Mill

- A powerful 90V DC motor with electronic speed controller

- 14″ base with laser-engraved scales

- Brass leadscrew cover that keeps chips off the rear of the Y-axis leadscrew

- 2.75″ (70 mm) x 13.0″ (330 mm) table with laser-engraved scales and two T-slots

- 2" column riser block

- Resettable, zero-adjustable handwheels that can be mounted to the end of the stepper motors to maintain manual control when needed:

- (2) 2″ (51 mm) handwheels on X- and Y-axes

- (1) 2-1/2″ (63 mm) handwheel on Z-axis

- All with laser-engraved aluminum collars

- NOTE: CNC-ready machines cannot be operated manually unless double-shaft stepper motors are installed.

- ¼” Drill Chuck w/ key, #1 Morse arbor with drawbolt

- Pulleys, drive belt, three hexagonal keys, spindle bars, gib removal tool, eight-foot three-wire power cord, and instruction manual

- Oil reservoirs on the X/Y axes and the Z axis help keep critical parts lubricated. These were initially developed for CNC machines that run constantly for hours on end but can benefit manual machines as well