Product Description

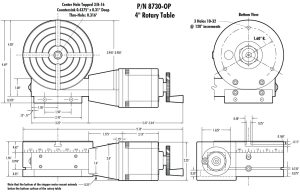

About the CNC 4″ Rotary Table Indexer with Reverse Mount

The reverse rotary table is perfect for use on the tilting angle table. The reverse mount allows access to the handwheel from the front of the machine (see photo below). If you used a standard rotary table in the previously described set-up, the handwheel would be mounted facing the backside of the X-axis.

NOTE: When the worm housing is reversed to the opposite side, a clockwise rotation of the handwheel or stepper motor will result in a counter-clockwise rotation of the rotary table.

Sherline has taken their accurate and reliable 4″ rotary table into the 21st century with the addition of Computer Numeric Control. Clock-makers or anyone with a need to cut gears or other complicated radially symmetrical patterns will find this accessory takes all the headaches out of repetitive indexing operations.

All entries are made from this simple keypad. No separate computer is needed. You get everything you need, including the 4″ Sherline rotary table with an installed stepper motor, microprocessor unit with numeric input keypad, 115 VAC power source, and all necessary connecting cables.

All entries are made from this simple keypad. No separate computer is needed. You get everything you need, including the 4″ Sherline rotary table with an installed stepper motor, microprocessor unit with numeric input keypad, 115 VAC power source, and all necessary connecting cables.

Vertical Mounting Options

The rotary table comes with clamps and T-nuts for attaching it to the T-slots of a Sherline mill table. In addition, there are two options available for mounting the table in the vertical position or at other angles:

Right-Angle Attachment—This plate holds the table in the vertical position with a center height of 2.7″. A right-angle tailstock is also available to support long stock held on center in the rotary table.

Tilting-Angle Table—This table holds the rotary table and can be fixed at any angle from 0° to 90°. In the 90° position, the rotary table center is also at the 2.7″ height that allows the right angle tailstock to be used with it.

Operation is very simple

After entering the number of steps per revolution (or the number of degrees per step) on a simple numeric keypad, the table advances quickly and precisely to the next position at the touch of a single advance key. If an error is made, previous positions can be accurately recalled by hitting another button. Basic resolution is 28,800 steps per revolution, ±0.006° per step. This allows the accurate machining of items like gears with odd numbers of teeth. Computations are made internally to a high degree of accuracy to avoid cumulative errors.

The CNC rotary indexer is a stand-alone unit. You get everything you need to make complex indexing jobs easy. In addition, the unit can be connected to an existing CNC control to act in conjunction with that system. An input signal triggers the programmed function. When it is complete, it signals back to continue the program. The unit can also be “daisy chained” with other units to trigger sequential actions. As with all Sherline accessories, complete instructions are included.

The rotary table can also be “daisy chained” with Sherline’s linear controller (P/N 8800) to achieve combinations of rotary and linear movement in sequence. This makes it easy to set up for relatively sophisticated operations like cutting gears without having to know anything about CNC programming beyond what is entered from these simple keypads.

NOTE: We are stating the following weight limits for our rotary tables for continual use.

- Horizontal orientation—50 lbs.

- Vertical orientation—30 lbs.

- Vertical rotational torque—6 foot/lbs. (meaning it can lift a 6 lb. weight when suspended 12″ away from the center of the rotary table)

The rotary tables can hold more weight when they are not under a continual load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

About the Controller Power Supply Current

The controller power supply is 110-240VAC compatible. It automatically switches from 110V to 240V for countries with 220-240 volt electrical current. The original power supply that we offered with this product was 110 VAC only.

Using the rotary table with the limit switches on the TAT

NOTE: For instructions on using the rotary table with the limit switches on the TAT, click on the Instructions tab above and download the PDF MASSO Rotary Table Limit Switch Interference on the Tilting Angle Table.